Composite salad sauce packaging membrane and preparation method thereof

A composite film and salad technology, which is applied in the field of packaging materials, can solve the problems of packaging contents eroding the glue layer, affecting the packaging and shelf life of the contents, and delamination of the glue layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

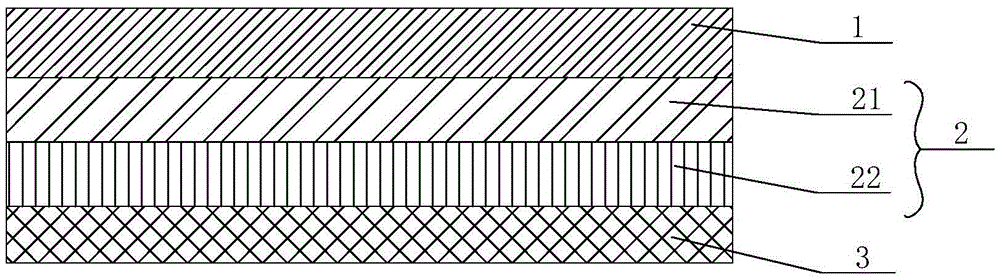

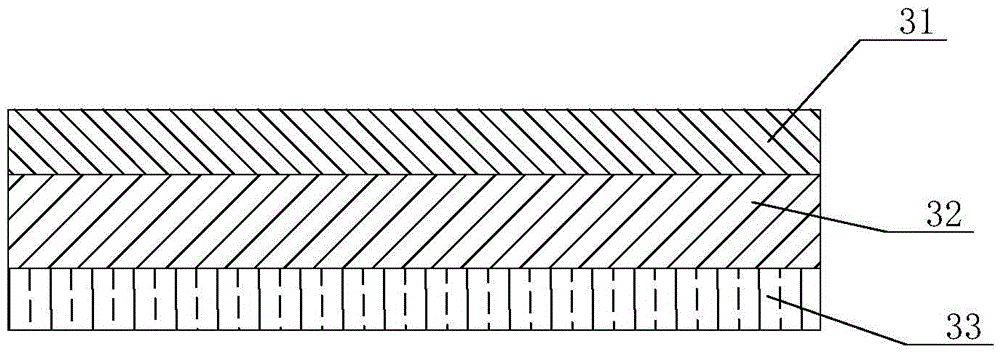

[0024] Such as Figure 1 to Figure 2 As shown, this specific embodiment adopts the following technical scheme: it includes successively connected 12 μm PET printing film layer 1, 15-20 μm functional polyethylene film layer 2, and 60-80 μm PE film layer 3 closely bonded together; The polyethylene film layer 2 is a double-layer co-extruded composite structure, and the side where the functional polyethylene film layer 2 is bonded to the PET printing film layer 1 is an ethylene acrylic acid copolymer layer 21; the functional polyethylene film layer 2 is bonded to the PE film layer 3. The side connected is low-density polyethylene and white masterbatch blending layer 22, and the weight ratio of low-density polyethylene and white masterbatch is 20~24:3; Described ethylene acrylic acid copolymer layer 21 and low-density polyethylene The thickness ratio of the blended layer 22 with the white masterbatch is 2:3-9:10.

[0025] Wherein, the grade of the ethylene acrylic acid copolymer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com