Improved modified Siemens process polycrystalline silicon reduction furnace base plate

A Siemens method and polysilicon technology, applied in the improvement field of polysilicon reduction furnace chassis, can solve the problems of low primary conversion rate of gas raw materials, uneven quality of polysilicon rods, and small production capacity, etc., to increase heat radiation utilization rate and primary conversion rate The effect of improving and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

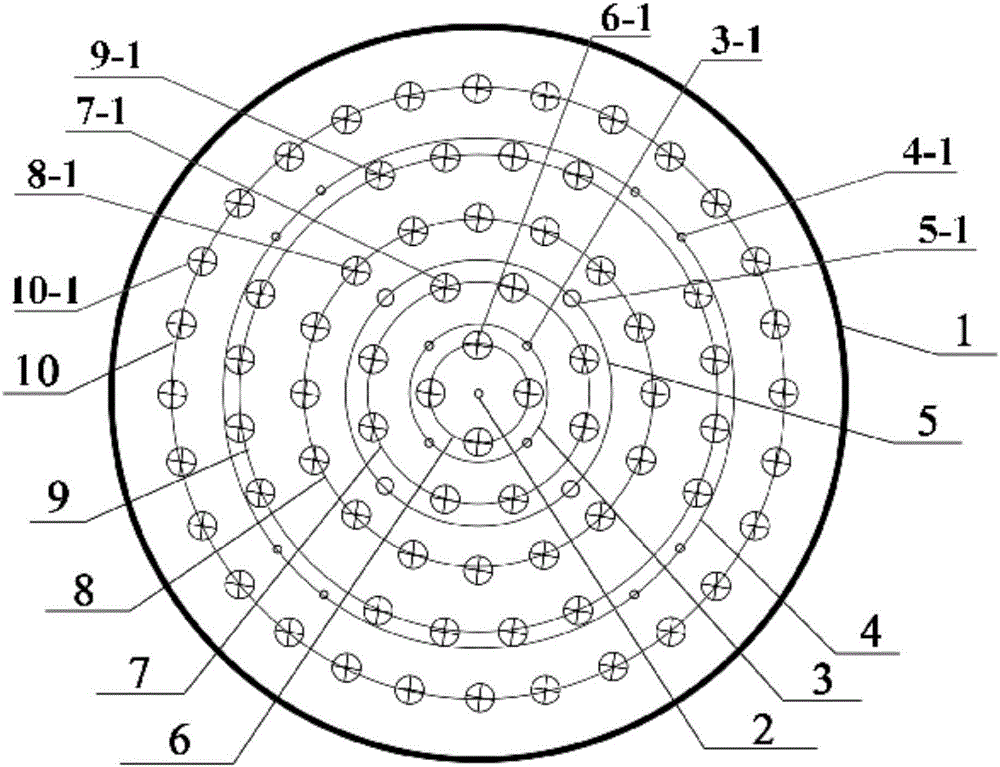

[0015] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. An improved modified Siemens method polysilicon reduction furnace chassis of this embodiment includes a chassis 1, 4 first electrodes 6-1, 8 second electrodes 7-1, 16 third electrodes 8-1, and 16 fourth electrodes Electrode 9-1, 28 fifth electrodes 10-1, 1 chassis center air intake nozzle 2, 4 first air intake nozzles 3-1 and 8 second air intake nozzles 4-1;

[0016] The four first electrodes 6-1 are evenly arranged on the ring-shaped center line 6 of the first electrode ring, and the linear distance between the centers of two adjacent first electrodes 6-1 is 190 mm to 230 mm; the average of the eight second electrodes 7-1 It is divided into 4 second electrode groups, and the 4 second electrode groups are evenly arranged on the center line 7 of the electrode ring ring, and the straight-line distance between the centers of two adjacent second electrodes 7...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: the chassis 1 is a disc structure. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the diameter of the chassis 1 is 2500mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com