A method for recovering h2s and nh3 in acidic water and purifying acidic water

A sour water and acid gas technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complex process, long start-up time, high energy consumption, etc., and achieve the effect of complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

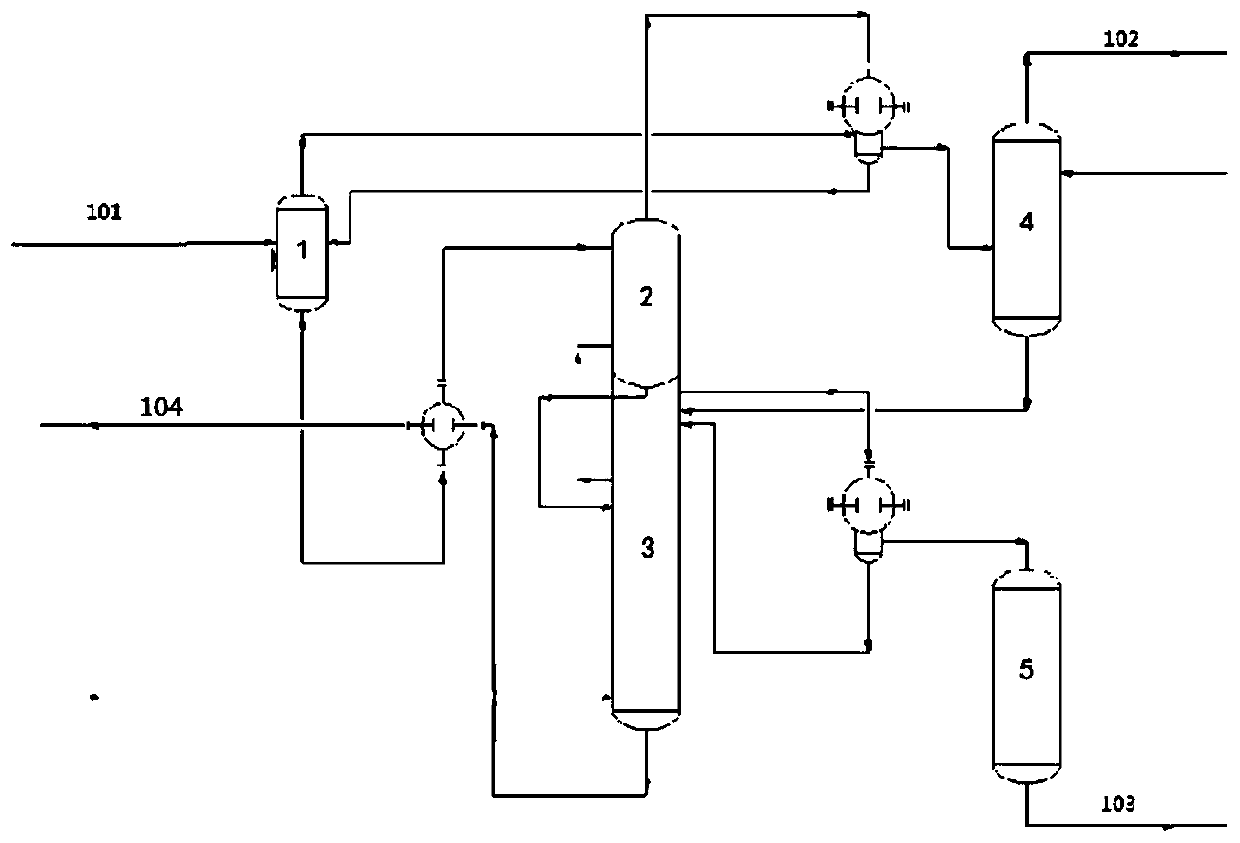

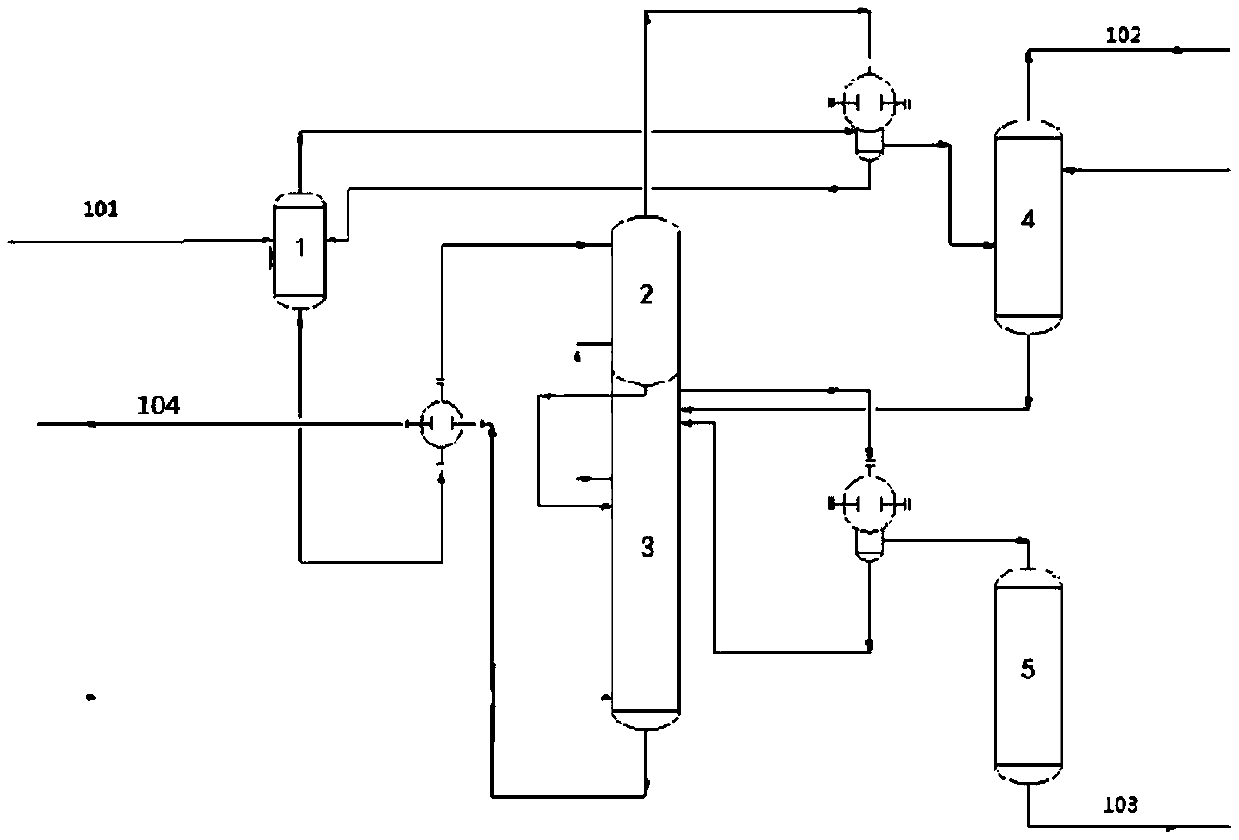

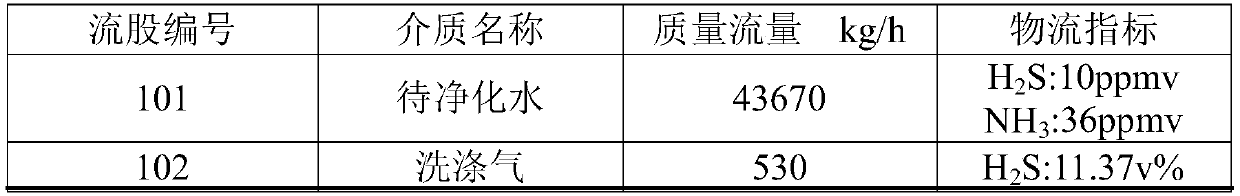

[0048] 1) According to figure 1 In the process shown, the acidic water to be purified (stream 101) from devices such as purification transformation, tail gas hydrogen production, low-temperature methanol washing, sulfur recovery and oil processing enters the degassing tank 1 together, and is operated at 47°C and 0.22MPa Perform flash evaporation under conditions to obtain flash gas and acidic water I; wherein, the flash gas obtained at the top of the tank enters the carbon dioxide stripping tower top condenser; the acidic water I obtained at the bottom of the tank is in the acidic water-purified water heat exchanger After exchanging heat with qualified purified acidic water and raising the temperature to 95°C, it enters the carbon dioxide stripping tower 2.

[0049] 2) step 1) gained sour water 1 flows from top to bottom in the carbon dioxide stripper 2 and carries out CO 2 and H 2 For the stripping of S, the operating pressure at the top of the carbon dioxide stripping towe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com