Technological improvement method for preparing trelagliptin succinate

A technology for improving the technology of troxagliptin succinate and process, which is applied in the field of preparation of troxagliptin succinate, can solve problems such as unsuitability for industrialized production, complicated process routes, and insufficient environmental protection of solvents, and achieve the goal of overcoming cumbersome industrial operations and simplifying the process. The effect of operation process and environmental pollution is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

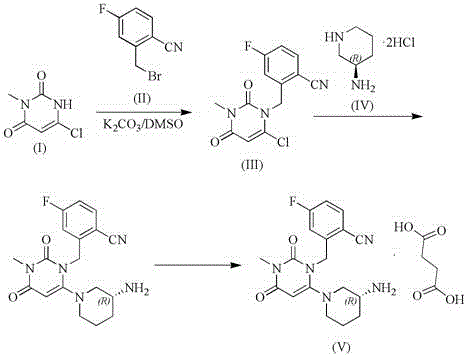

[0029] Example 1: One-pot method for preparing trexagliptin succinate

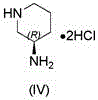

[0030] Add 15g of 6-chloro-3-methyluracil, 22.1g of 2-cyano-5-fluorobenzyl bromide and 150ml of ethanol into a 500ml three-necked flask. Add 39.3g NaHCO with stirring 3 , heated to reflux at 80°C for 3 hours. Add 24 g of (R)-3-aminopiperidine dihydrochloride and reflux at 80°C for 2 hours. Cool to 40°C, add 60ml of dichloromethane, and stir for 0.5 hours. After filtration, the filtrate was added to a 250ml three-neck flask, 16.6g of succinic acid was added, and heated to reflux at 80°C for 1 hour. Stir and cool overnight, filter, and put the filter cake into a blast drying oven to dry at 60°C to obtain 28.6 g of off-white crystalline powder (Trexagliptin succinate, compound V), with a yield of 64% and a purity of 99% by HPLC. See attached figure 1 ,Data are as follows:

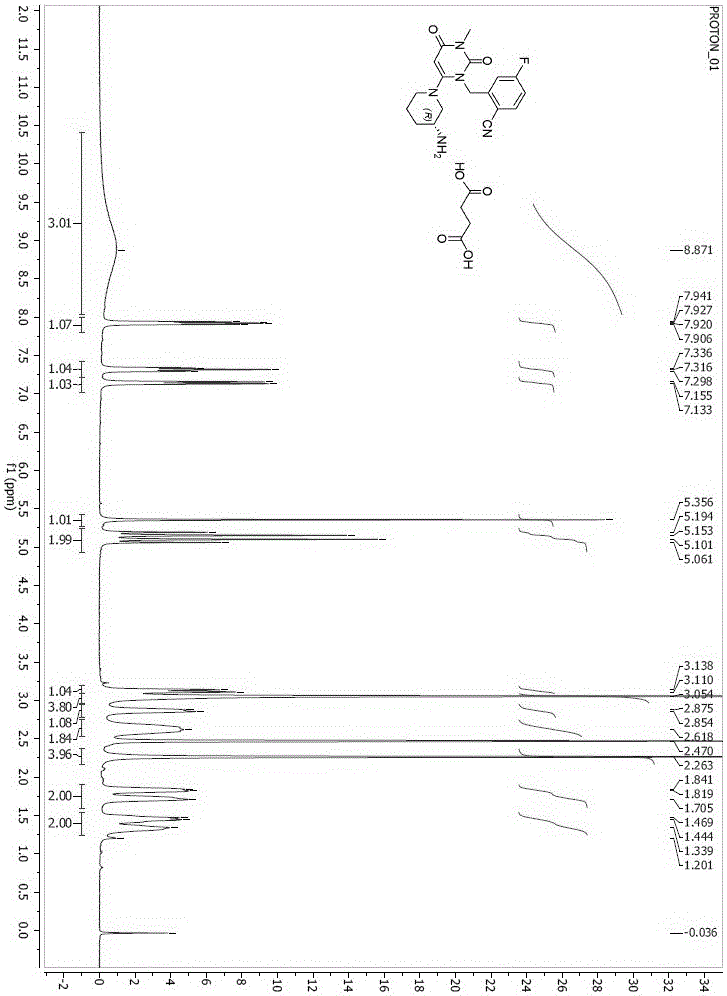

[0031] 1H NMR (400 MHz, dmso) δ 8.87 (s, 3H), 7.92 (dd, J = 8.4, 5.6 Hz, 1H), 7.32 (t, J = 7.6 Hz, 1H), 7.14 (d, J = 9.0 Hz , 1H)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com