Energy-saving environment-friendly polycarboxylic acid water reducing agent, and preparation method thereof

A technology of energy saving, environmental protection and water reducing agent, applied in the field of chemical building materials, can solve the problems of high production cost, complex production process, unenvironmental protection, etc., and achieve the effect of saving construction cost, good adaptability, and no three wastes discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

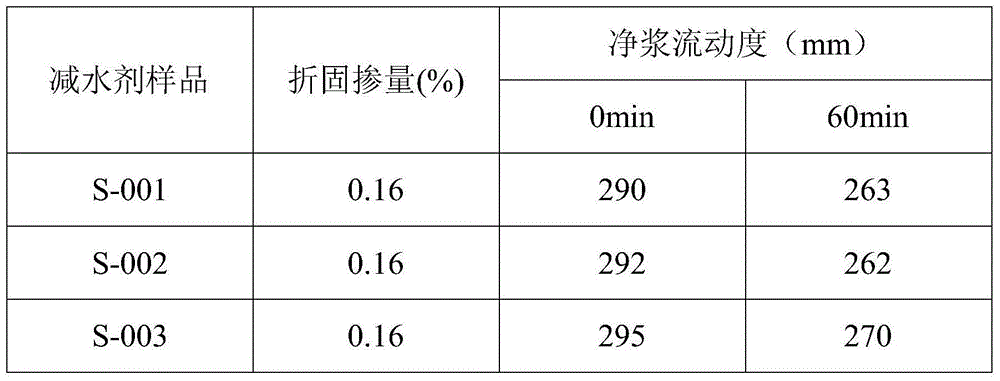

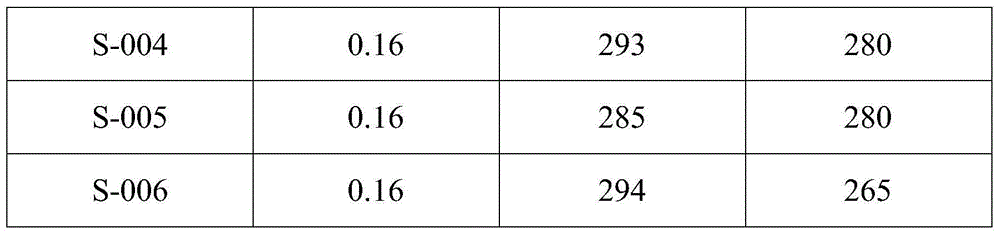

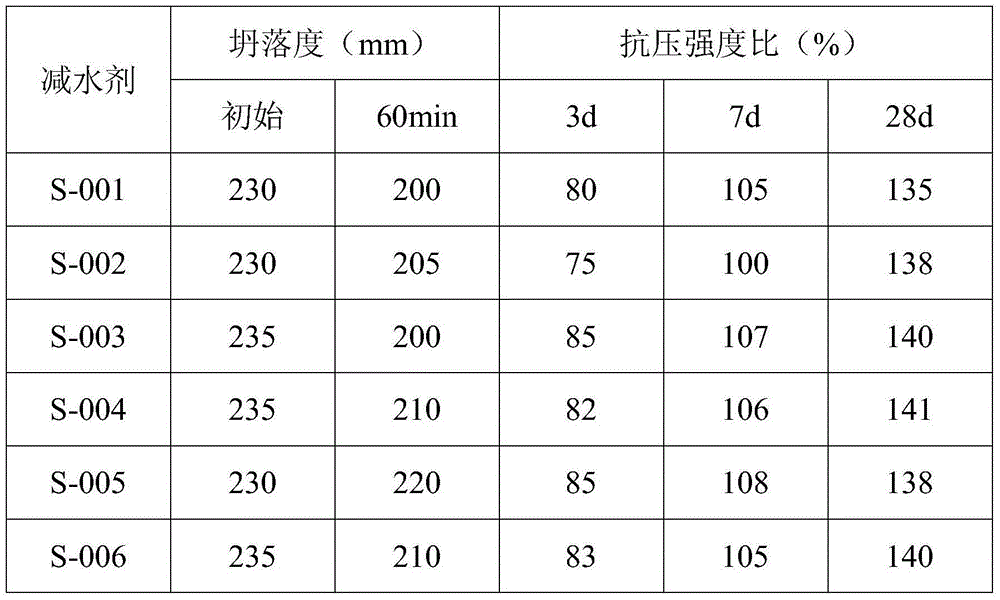

Examples

Embodiment 1

[0025] ① Add 25.0g of methacrylic acid, 0.5g of sodium bisulfite, 0.2g of thioglycolic acid, add 20g of water, stir well, and use it as liquid A for later use.

[0026] ②Add 2.0g of hydrogen peroxide to 25g of water, stir evenly, and use it as liquid B for later use.

[0027] ③ Add well water: 200g into a 500ml four-necked flask equipped with a thermometer and stirring equipment, add 220g of HPEG (isobutylene alcohol polyoxyethylene ether) macromonomer, and stir for 10 minutes.

[0028] ④ Use a peristaltic pump to add liquid A and liquid B in parallel at a constant speed, and the time for adding liquid A and liquid B is controlled within 2 hours.

[0029] ⑤ After the dropwise addition is completed, continue to react for 30 minutes, and the finished product is made after the reaction is completed.

[0030] In this example, the conductivity of well water is 800us / cm, the initial temperature of feeding is 15°C, and the product number is marked as: S-001.

Embodiment 2

[0032] ① Add 25.0g of methacrylic acid, 0.5g of sodium bisulfite, 0.2g of thioglycolic acid, add 20g of water, stir well, and use it as liquid A for later use.

[0033] ②Add 2.0g of hydrogen peroxide to 25g of water, stir evenly, and use it as liquid B for later use.

[0034] ③In a 500ml four-necked flask equipped with a thermometer and stirring equipment, add shallow well water: 120g, add 220g of HPEG (isobutylene alcohol polyoxyethylene ether) macromonomer, and stir for 10 minutes.

[0035] ④ Use a peristaltic pump to add liquid A and liquid B in parallel at a constant speed, and the time for adding liquid A and liquid B is controlled within 2 hours.

[0036] ⑤ After the dropwise addition is completed, continue to react for 30 minutes, and the finished product is made after the reaction is completed.

[0037] In this example, the conductivity of well water is 2200us / cm, the initial temperature of feeding is 6°C, and the product number is marked as: S-002.

Embodiment 3

[0039] ①Acrylic acid 20.0g, L-ascorbic acid 0.8g, thioglycolic acid 0.2g, mercaptopropionic acid 0.5g add water 25g, stir evenly, use as A solution for later use.

[0040] ② Add 3.0g of hydrogen peroxide, add 24g of water, stir evenly, and use it as liquid B for later use.

[0041] ③Add well water: 200g into a 500ml four-necked flask equipped with a thermometer and stirring equipment, add 230g of HPEG (isobutylene alcohol polyoxyethylene ether) macromonomer, and stir for 10 minutes.

[0042] ④ Use a peristaltic pump to add liquid A and liquid B in parallel at a constant speed. The feeding time of liquid A is 3 hours, and the feeding time of liquid B is 2 hours.

[0043] ⑤ After the dropwise addition is completed, continue to react for 30 minutes, and the finished product is made after the reaction is completed.

[0044] In this example, the conductivity of well water is 800us / cm, the initial temperature of feeding is 8°C, and the product number is marked as: S-003.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com