Polyurethane foam material with carbon dioxide as environment-friendly latent foaming agent and preparing method thereof

An environmentally friendly, polyurethane foam technology, applied in the field of rigid polyurethane foam material preparation, to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] (1) The preparation method of the ammonium salt described in the formula of table 1 is as follows:

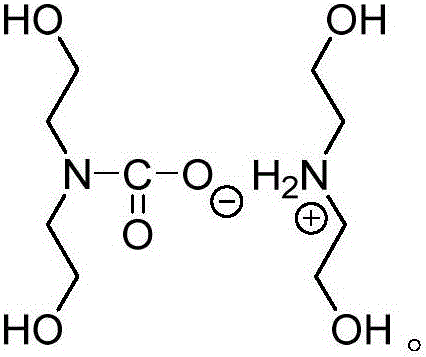

[0021] Diethanolamine was added into a three-necked flask, and reacted for 7 hours at a stirring speed of 250 rpm and a carbon dioxide feeding rate of 60 ml / min to obtain a transparent viscous ammonium salt (ammonium dihydroxyethylcarbamate).

[0022] (2) In parts by weight, take polyether polyol (polyether 430 produced by Changzhou Luoyang New Material Thermal Insulation Material Factory), ammonium dihydroxyethyl carbamate, isocyanate (produced by Yantai Wanhua Chemical Group Co., Ltd. PM-200), foam stabilizer 8804, catalyst PC-8, the formula of embodiment is as shown in table 1.

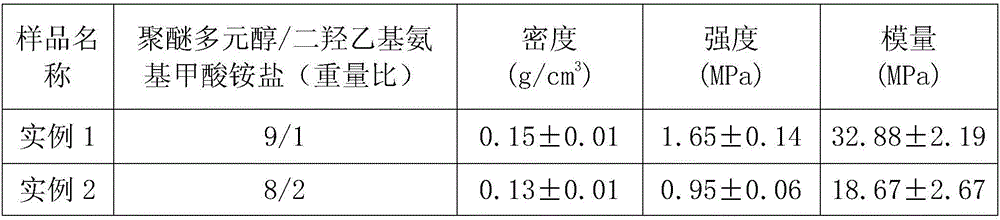

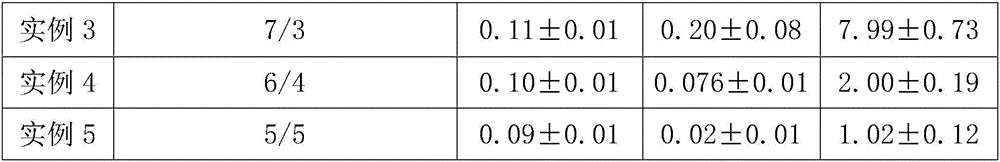

[0023] Table 1 is the raw material formula of rigid polyurethane foam

[0024] Raw material number Example 1 Example 2 Example 3 Example 4 Example 5 Polyether polyol 430 90.00 80.00 70.00 60.00 50.00 Ammonium Dihydroxyethylcarbamate 10.00 20.00 30.00 40....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com