Polyamide composition and preparation method thereof

A technology of composition and polyamide, which is applied in the field of polyamide composition and its preparation, can solve the problems affecting whiteness, etc., and achieve the effect of good product color and maintaining combustion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

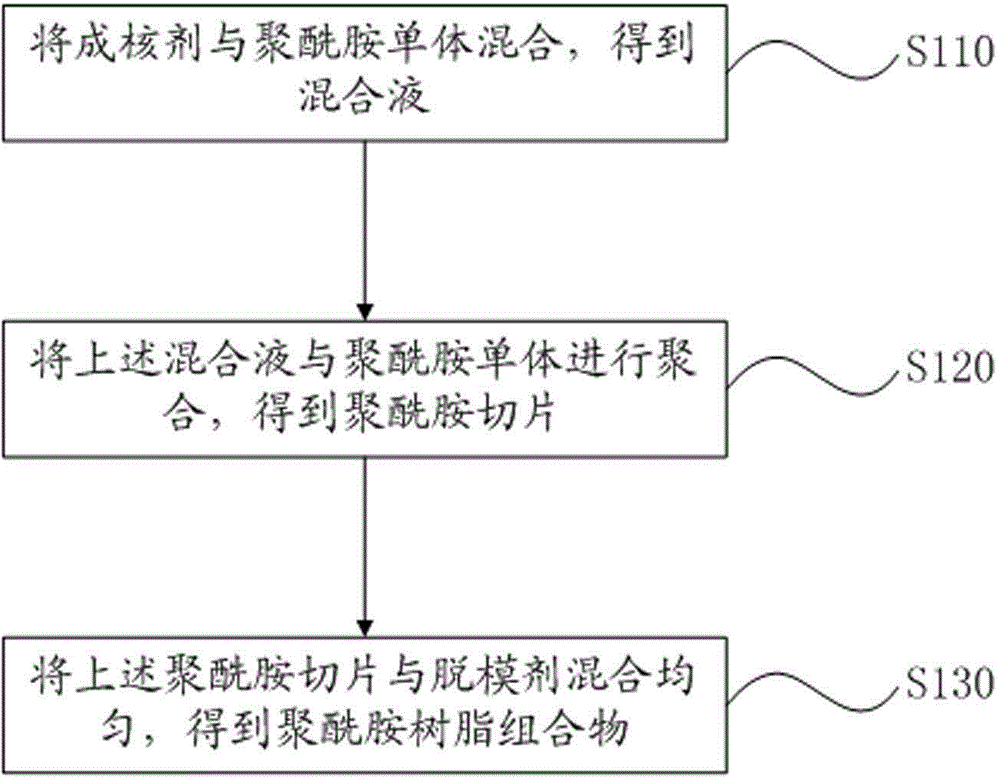

[0040] see figure 1 , a preparation method of a polyamide resin composition, comprising the following steps:

[0041] S110, mixing the nucleating agent and the polyamide monomer to obtain a mixed liquid.

[0042] Wherein, the nucleating agent is nylon 22, silicon dioxide or talcum powder.

[0043] In this embodiment, the mass percentage of the nucleating agent in the mixed liquid is 1%-10%.

[0044] Preferably, the mass percent content of the nucleating agent in the mixed solution is 2% to 6%.

[0045] S120. Polymerizing the above mixed solution with polyamide monomers to obtain polyamide chips.

[0046] Wherein, the polyamide slice is a polymer slice with amide repeating units on the polymer chain.

[0047] Polyamide slices are polyamide 6 slices, polyamide 66 slices, polyamide 610 slices, polyamide 612 slices, polyamide 1010 slices, polyamide 11 slices, polyamide 12 slices or copolyamide 6 / 66 slices.

[0048] It can be understood that the polyamide monomers used in step...

Embodiment 1

[0059] Mix nylon 22 and caprolactam to prepare a mixed solution with a mass content of nylon 22 of 5%. Mix the mixture with caprolactam at a ratio of 2:98, enter the polymerization reactor, polymerize under normal pressure for 12 hours, melt-cast and cut into pellets, extract with desalted water at 98°C for 24 hours, and dry with hot nitrogen for 16 hours to obtain Polyamide 6 slices. It was determined that the relative viscosity of polyamide 6 chips was 2.52, and the extractables were 0.35%.

[0060]The above-mentioned polyamide 6 slices were fed into a conical mixer, 0.15% of partially saponified montanic acid ester wax was added, mixed at 80°C for 20 minutes, and after cooling, a polyamide resin composition was obtained without any separated powder.

[0061] The above polyamide resin composition contains 0.1% of nylon 22, 0.15% of partially saponified montan ester and 99.75% of polyamide 6.

[0062] Using the polyamide resin composition prepared in Example 1, the metal pi...

Embodiment 2

[0070] The specific surface area is 130m 2 / g nano silicon dioxide is mixed with caprolactam to prepare a mixed solution with a mass content of silicon dioxide of 3%. Mix the mixture with caprolactam at a ratio of 4:96, enter the polymerization reactor, polymerize under normal pressure for 12 hours, melt-cast and cut into pellets, extract with desalted water at 98°C for 24 hours, and dry with hot nitrogen for 16 hours to obtain Polyamide 6 slices. It was determined that the relative viscosity of polyamide 6 chips was 2.57, and the extractables were 0.41%.

[0071] The above-mentioned polyamide 6 slices were sent into a conical mixer, a mixture of 0.05% ethylene glycol montanate and 0.1% stearyl stearamide was added, mixed at 80°C for 20 minutes, and a polyamide resin composition was obtained after cooling. No isolated powder was present.

[0072] The above polyamide resin composition contains 0.12% of silica, 0.15% of a release agent and 99.83% of polyamide 6.

[0073] Usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com