Carbon felt-enhanced phenolic aldehyde ethylene propylene diene monomer-based thermal insulation material and preparation method thereof

A technology of EPDM rubber and thermal insulation material, which can be applied in coating and other directions, can solve problems such as increasing material cost, and achieve the effects of improving production efficiency, improving the uniformity of glue content and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples.

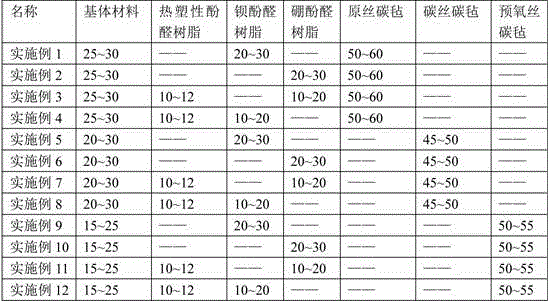

[0023] A carbon felt-reinforced phenolic EPDM rubber-based thermal insulation material, the formulation and component specifications of which are shown in Table 1, and the unit is parts by weight.

[0024]

[0025] Table 1

[0026] The raw silk carbon felt, carbon silk carbon felt or pre-oxygenated silk carbon felt are all provided by Shanxi Institute of Coal Chemistry, Chinese Academy of Sciences.

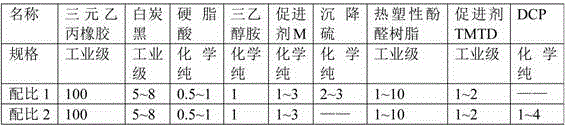

[0027] The EPDM base material described in the present invention is made of EPDM rubber, white carbon black, stearic acid, triethanolamine, accelerator M, accelerator TMTD, thermoplastic phenolic resin, settled sulfur or DCP, The formulation specifications are shown in Table 2; the EPDM base material is prepared through the rubber mixing process, then sampled and vulcanized, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com