Method for treating waste oil-based drilling cuttings produced by oil field drilling operation

A technology for oil field drilling and oil-based drilling cuttings, which is applied in the field of treatment of waste oil-based drilling cuttings produced by oilfield drilling operations, can solve the problems of oilfields failing to meet environmental protection requirements and meet the standard treatment technology, etc., and achieve harmless treatment and eliminate pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

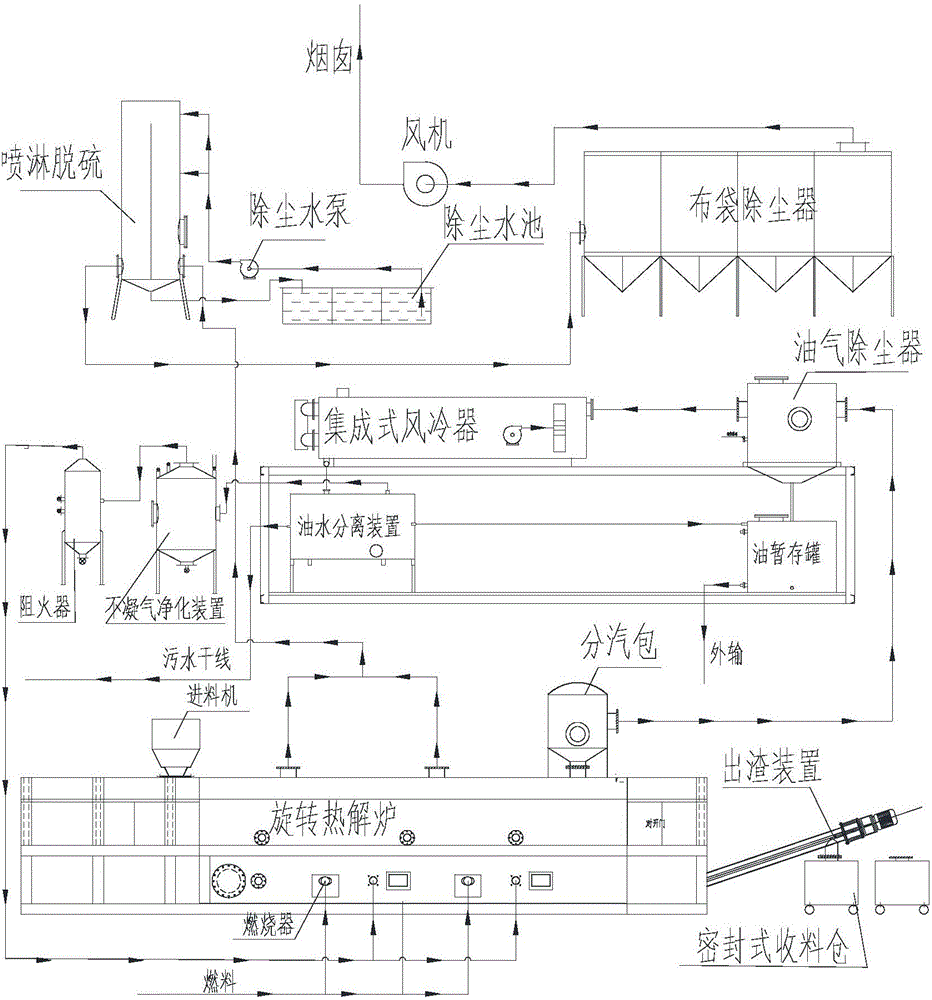

Image

Examples

Embodiment 1

[0028] Harmless treatment of waste oil-based drilling cuttings produced by about 1,000 tons of drilling operations in Daqing Oilfield, and a set of 24t / d oxygen barrier indirect heating rotary furnace pyrolysis process, with a treatment period of about 1.5 months. Before feeding materials, start the nitrogen making system to fill nitrogen into the rotary pyrolysis furnace to drive away the air to ensure an oxygen-isolated environment in the pyrolysis furnace; at the same time, according to the temperature control system settings, light the burner in the combustion chamber to reduce the temperature Control the temperature between 150°C and 180°C, control the temperature in the analysis chamber between 300°C and 400°C, ensure that the rotation speed of the rotary pyrolysis furnace is 1r / min, and start feeding. The material is continuously transported to the sealed chamber of the rotary pyrolysis furnace through a fully enclosed pipeline at a rate of 1t / h by a mud pump. The resid...

Embodiment 2

[0033] Daqing Oilfield conducts harmless treatment of about 300t of waste oil-based drilling cuttings generated from drilling operations, and provides a set of 12t / d oxygen barrier indirect heating rotary furnace pyrolysis process, with a treatment period of one month. Before feeding materials, start the nitrogen making system to fill nitrogen into the rotary pyrolysis furnace to drive away the air to ensure an oxygen-isolated environment in the pyrolysis furnace; at the same time, according to the temperature control system settings, light the burner in the combustion chamber to reduce the temperature Control the temperature between 150°C and 180°C, control the temperature in the analysis chamber between 300°C and 400°C, ensure that the rotation speed of the rotary pyrolysis furnace is 1r / min, and start feeding. The material is continuously transported to the sealed chamber of the rotary pyrolysis furnace through a mud pump at a rate of 0.5t / h through a fully enclosed pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com