Process for preparing block-shaped nano-sized iron oxide coating through flame method

A technology of nano-iron oxide and flame method, which is applied in the field of environmental analysis and nano-materials to achieve the effects of easy control, high efficiency and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Take an iron wire with Φ=0.25 mm, first use 1.0M dilute hydrochloric acid to ultrasonically clean it for 15 minutes, then use acetone to ultrasonically clean it for 10 minutes, and finally use ultrapure water to ultrasonically clean it for 10 minutes; isolate the air and dry it for later use;

[0022] (2) Manually ignite the lighter, put one end of the cleaned iron wire into the inner flame position of the flame, burn for 5 s, and make nano iron oxide on the surface of the iron wire;

[0023] (3) Rinse the burnt iron wire with ultrapure water for 3 minutes, then with methanol for 8 minutes, and dry it in isolation from the air to obtain a uniform nano-iron oxide coating on the surface of the iron wire.

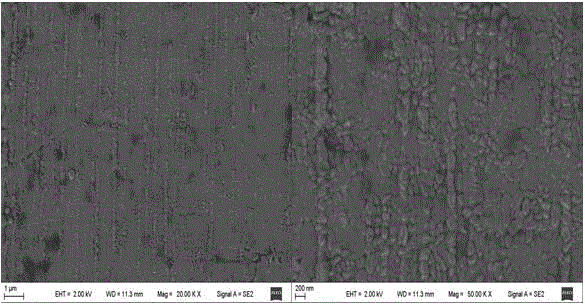

[0024] The SEM image of the prepared nano-iron oxide coating is attached figure 1 (The picture on the left is an SEM picture with a magnification of 20,000 times, and the picture on the right is an SEM picture with a magnification of 50,000 times.). Depend on figu...

Embodiment 2

[0026] (1) Take Φ=0.25 mm stainless steel wire, first use 1.5M oxalic acid to ultrasonically clean it for 15 minutes, then use acetone to ultrasonically clean it for 10 minutes, then use ultrapure water to ultrasonically clean it for 10 minutes, dry it in isolation, and set aside;

[0027] (2) Manually ignite the lighter, put one end of the cleaned stainless steel wire into the inner flame position of the flame, burn for 10 s, and prepare nano-iron oxide on the surface of the stainless steel wire;

[0028] (3) Rinse the burnt stainless steel wire with ultrapure water for 5 min, then with methanol for 8 min, and store it in an air-isolated dry place to obtain a uniform nano-iron oxide coating on the surface of the stainless steel wire.

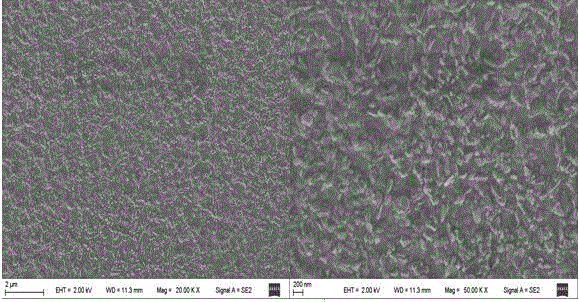

[0029] The SEM image of the prepared nano-iron oxide coating is shown in figure 2 (The picture on the left is an SEM picture with a magnification of 20,000 times, and the picture on the right is an SEM picture with a magnification of 50,000 ti...

Embodiment 3

[0031] (1) Take a piece of Φ=0.35 mm iron wire, first use 1.5M phosphoric acid to ultrasonically clean the iron wire for 15 minutes, then use acetone to ultrasonically clean it for 10 minutes, and finally use ultrapure water to ultrasonically clean it for 10 minutes, isolate it from the air and dry it, and set it aside;

[0032] (2) Put one end of the cleaned iron wire into the outer flame position of the flame of the alcohol lamp, burn for 20 s, and make nano-iron oxide on the surface of the iron wire;

[0033] (3) Rinse the burnt iron wire with ultrapure water for 4 minutes, and then with methanol for 8 minutes, and store it in a dry place isolated from air to obtain a uniform nano-iron oxide coating.

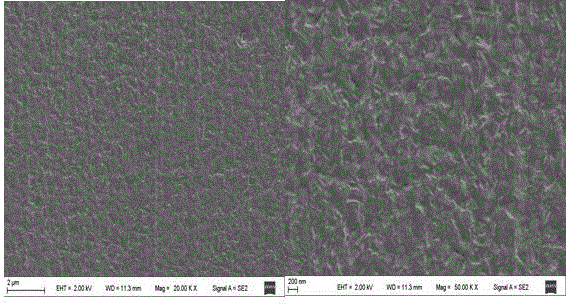

[0034] The SEM image of the prepared nano-iron oxide coating is shown in image 3 (The picture on the left is an SEM picture with a magnification of 20,000 times, and the picture on the right is an SEM picture with a magnification of 50,000 times.). Depend on image 3 It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com