Tarpaulin coating process

A tarpaulin and process technology, applied in the directions of coating, device for coating liquid on the surface, transportation and packaging, etc., can solve the problems of affecting the quality of tarpaulin finished products, long coating time, reducing manufacturing efficiency, etc. Uniform and reliable, short coating time, improved manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

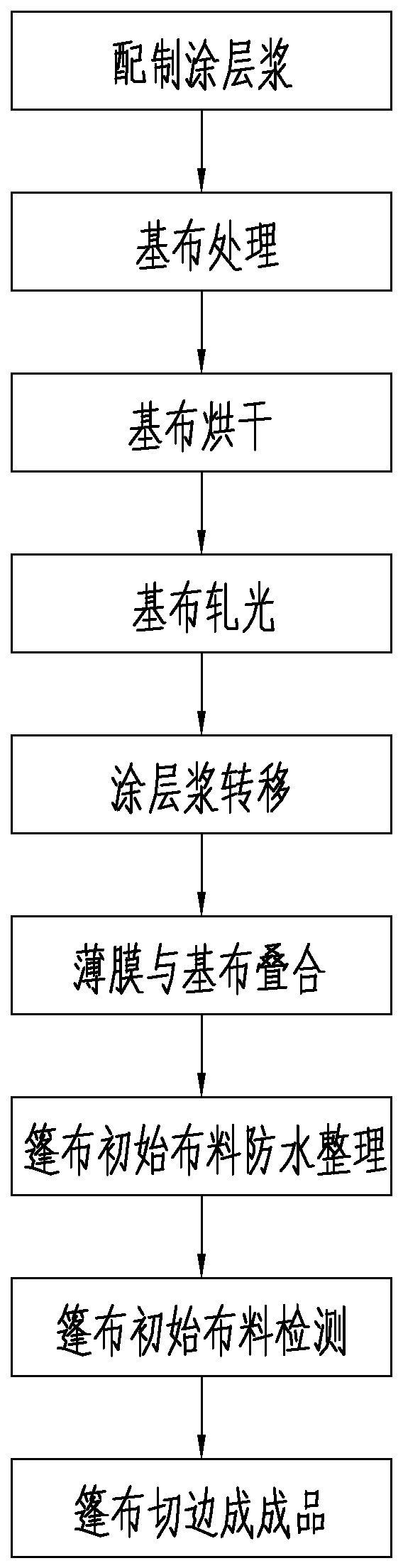

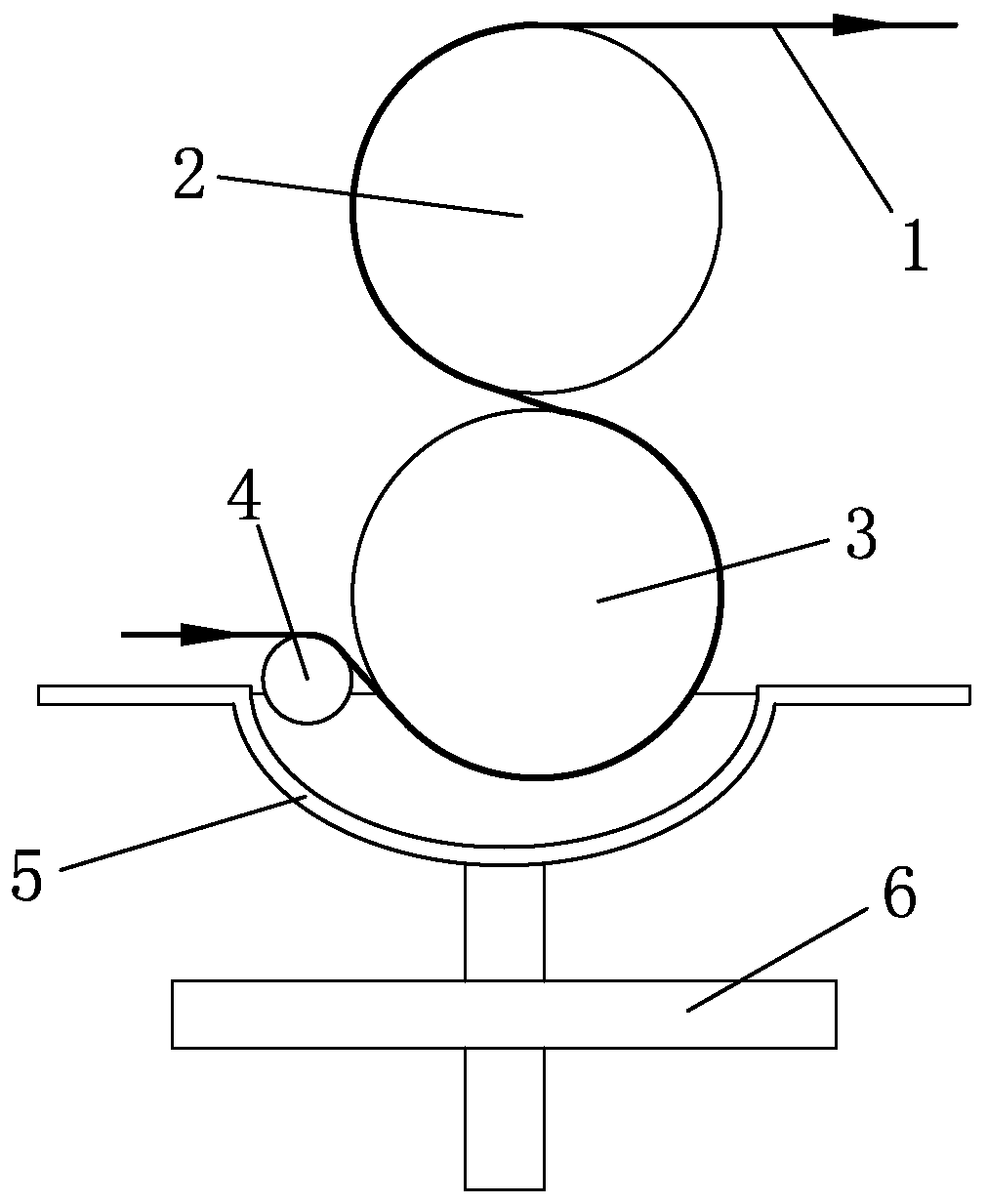

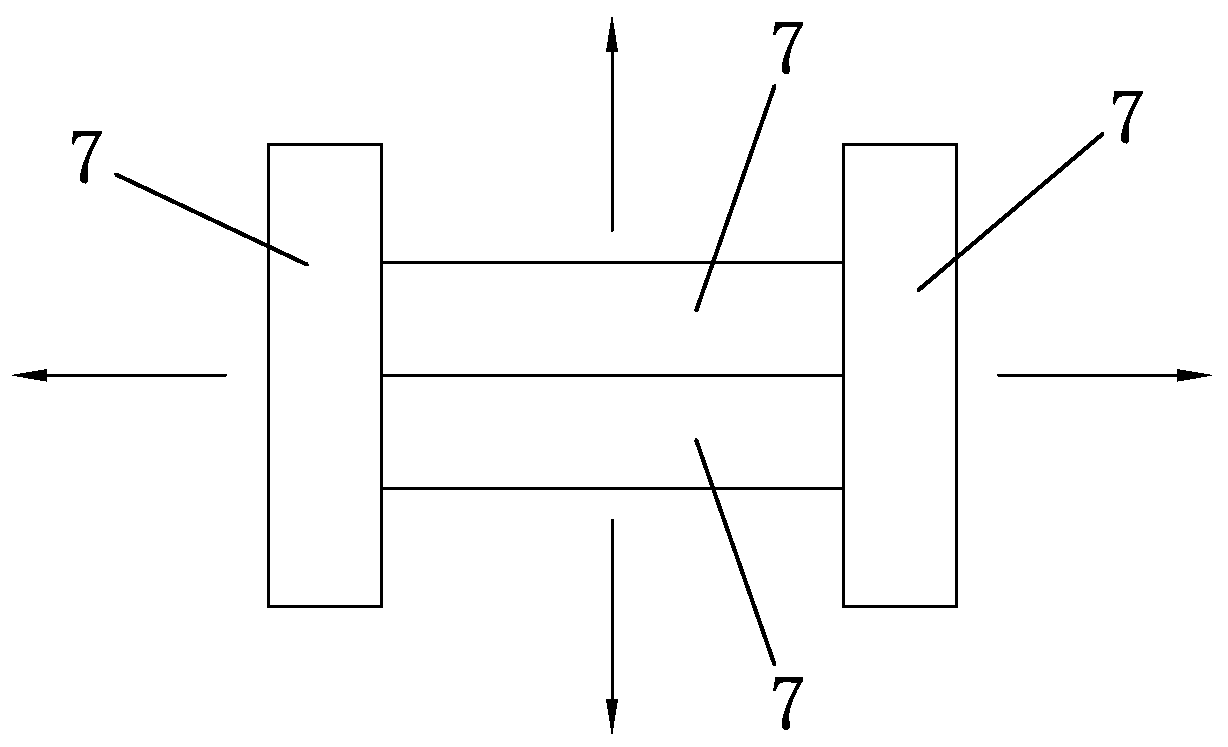

[0027] Such as Figure 1 to Figure 3 Shown, be tarpaulin coating technology involved in the present invention, specifically comprise the steps:

[0028] (a) Prepare coating slurry: disperse polyvinyl chloride solution in liquid plasticizer, swell and plasticize the mixed solution to form plastisol, then add emulsion, stabilizer, filler, colorant, and then stir, It is made into polyvinyl chloride paste resin, and then chemical additives are added to the polyvinyl chloride paste resin. The chemical additives are plasticizers, anti-fungal agents, anti-aging agents, antistatic agents, adhesives, and penetrating agents. , crosslinking agent and softener, etc. The dosage of each chemical additive is as shown in Table 1:

[0029]

[0030]

[0031] Table 1

[0032] The mixture of polyvinyl chloride paste resin and chemical additives is passed into the Z-type kneader through the screw feeding device, and then kneaded in the Z-type kneader, and then the mixture is sent to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com