Linear motor driving type plunger pump provided with multiple motion units

A linear motor and motion unit technology, applied in variable displacement pump components, machines/engines, liquid fuel engines, etc., can solve the problems of difficult automatic control, complex structure, high vibration and noise, etc., to reduce impact vibration and noise, The effect of meeting complex working conditions and improving life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

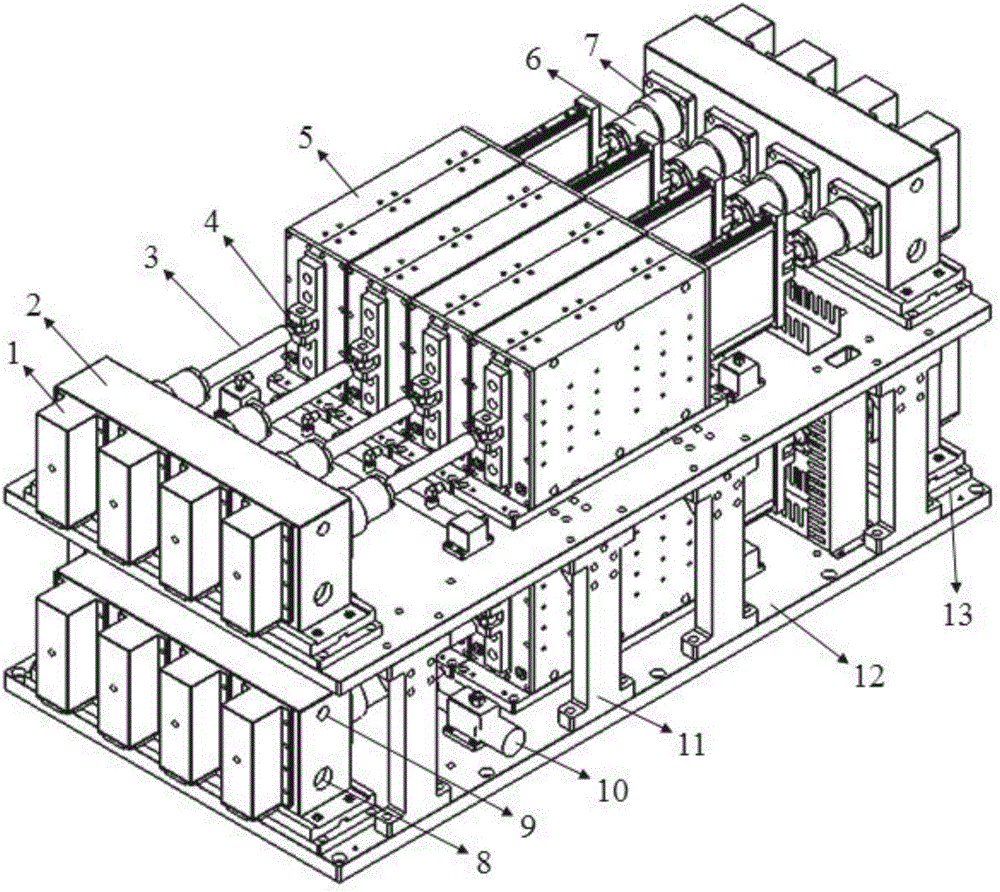

[0021] Such as figure 1 As shown, the present invention will be further described below through specific embodiments.

[0022] A multi-motion unit linear motor-driven plunger pump consists of two parts: a mechanical system and an electrical control system. The mechanical system mainly includes integrated distribution valve 1, cylinder body 2, plunger 3, end ball bearing 4, linear motor 5, cylinder barrel 6, cylinder barrel support flange 7, base 12, and cylinder body support base 13. The electrical control system mainly includes servo controller, driver, acquisition card, industrial computer, position feedback device, water cooler, etc.

[0023] The multi-motion unit linear motor-driven plunger pump consists of eight sets of linear motor units 5 arranged in two layers, each linear motor is driven by a corresponding driver, and the servo controller outputs control signals with a certain phase difference to the eight drivers. Thus, the linear motor mover is driven to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com