Calorimetric pool for uniformly adding mobile phase in calorimetric apparatus

A mobile phase, calorimetric technology, applied in the field of calorimetric cells, can solve problems such as poor mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

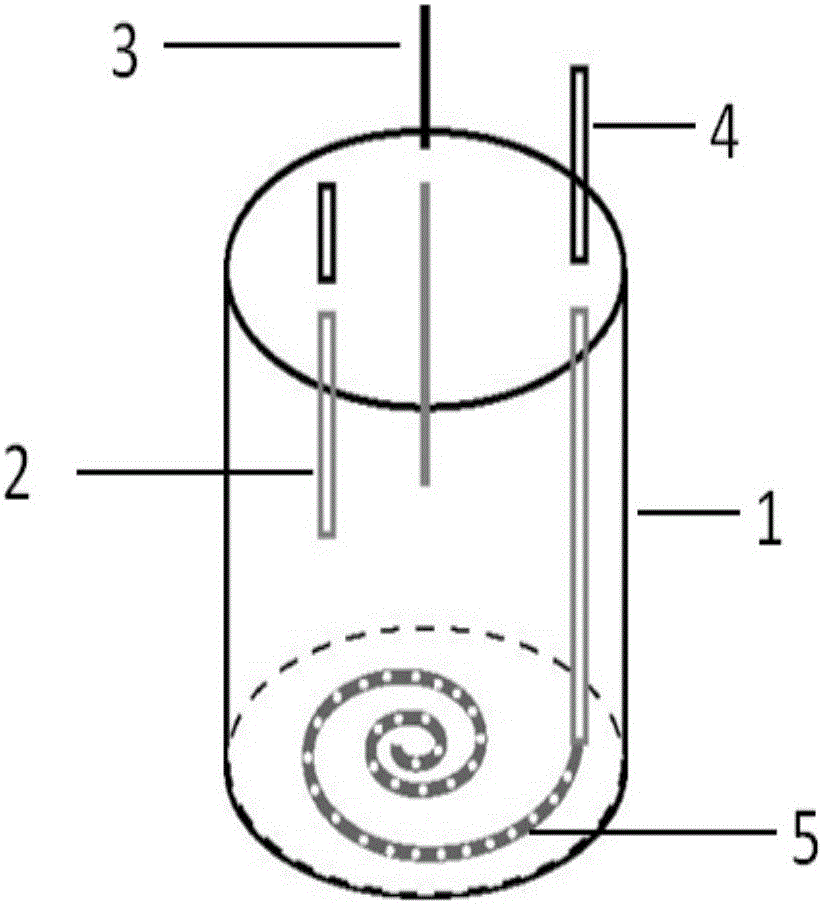

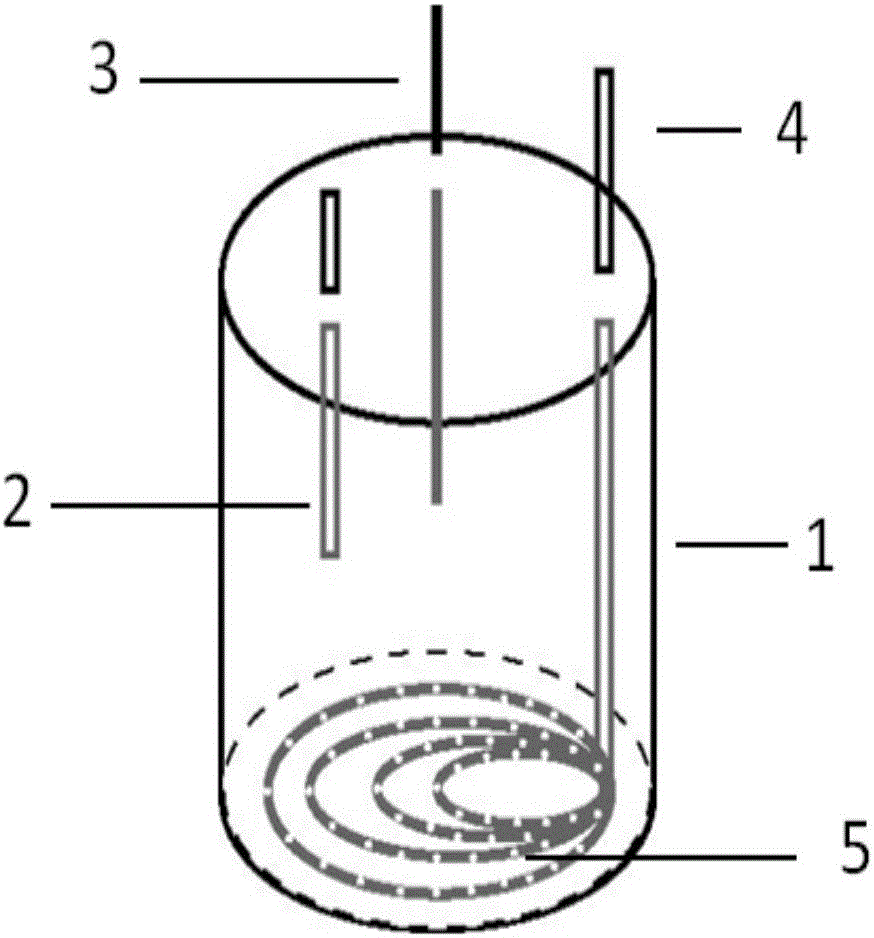

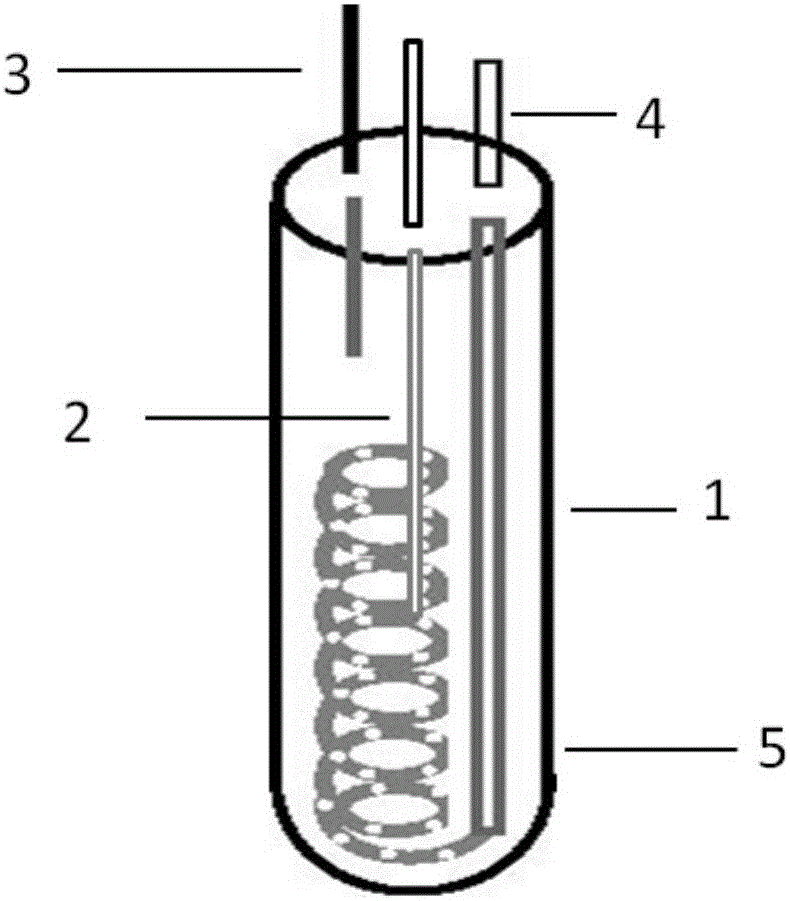

[0020] A calorimetric cell in which the mobile phase is uniformly added to the calorimetric device, such as figure 1 As shown, it includes reaction cell, reaction cell shell, temperature and pressure sensor probes, stationary phase injection port, mobile phase injection channel, porous disperser, and the top of the reaction cell is provided with a sleeve, and the temperature sensor probe is placed in the concave The pressure sensor probe is located in the gas phase space on the top of the reaction cell, the stationary phase injection port is located on the top of the reaction cell, the mobile phase injection channel is located on the top of the reaction cell, and extends into the reaction cell. One end is connected with a porous disperser, and the porous disperser is distributed at the bottom of the reaction pool in a flat manner or distributed in the space of the reaction pool in a spiral manner. The opening ratio of the porous disperser is 7%, and the porous disperser occupie...

Embodiment 2

[0042] According to the conditions and steps described in the examples, such as figure 2 As shown, the disperser is spread flatly at the bottom of the reaction pool, and the disperser is of the collar type. The shell of the reaction pool is thick-walled (such as ARC, C80), and the calorimetric equipment is the cumulative heat flow type. The porosity of the porous disperser is 5%, and the volume occupied by the porous disperser is 4% of the volume of the reaction tank.

Embodiment 3

[0044] According to the conditions and steps described in the examples, such as image 3 As shown, the disperser is spirally distributed in the space of the reaction pool, and the disperser is a ring type. The porosity of the porous disperser is 10%, and the volume occupied by the porous disperser is 5% of the volume of the reaction tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com