A Method for Detection and Precise Location of Small Leakage Sources in Pressure Pipelines

A pressure pipeline and precise positioning technology, which is applied to the processing of detection response signals, instruments, and material analysis using acoustic wave emission technology. It can solve problems such as confusing positioning data and difficulty in locating leak sources, so as to achieve precise positioning and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

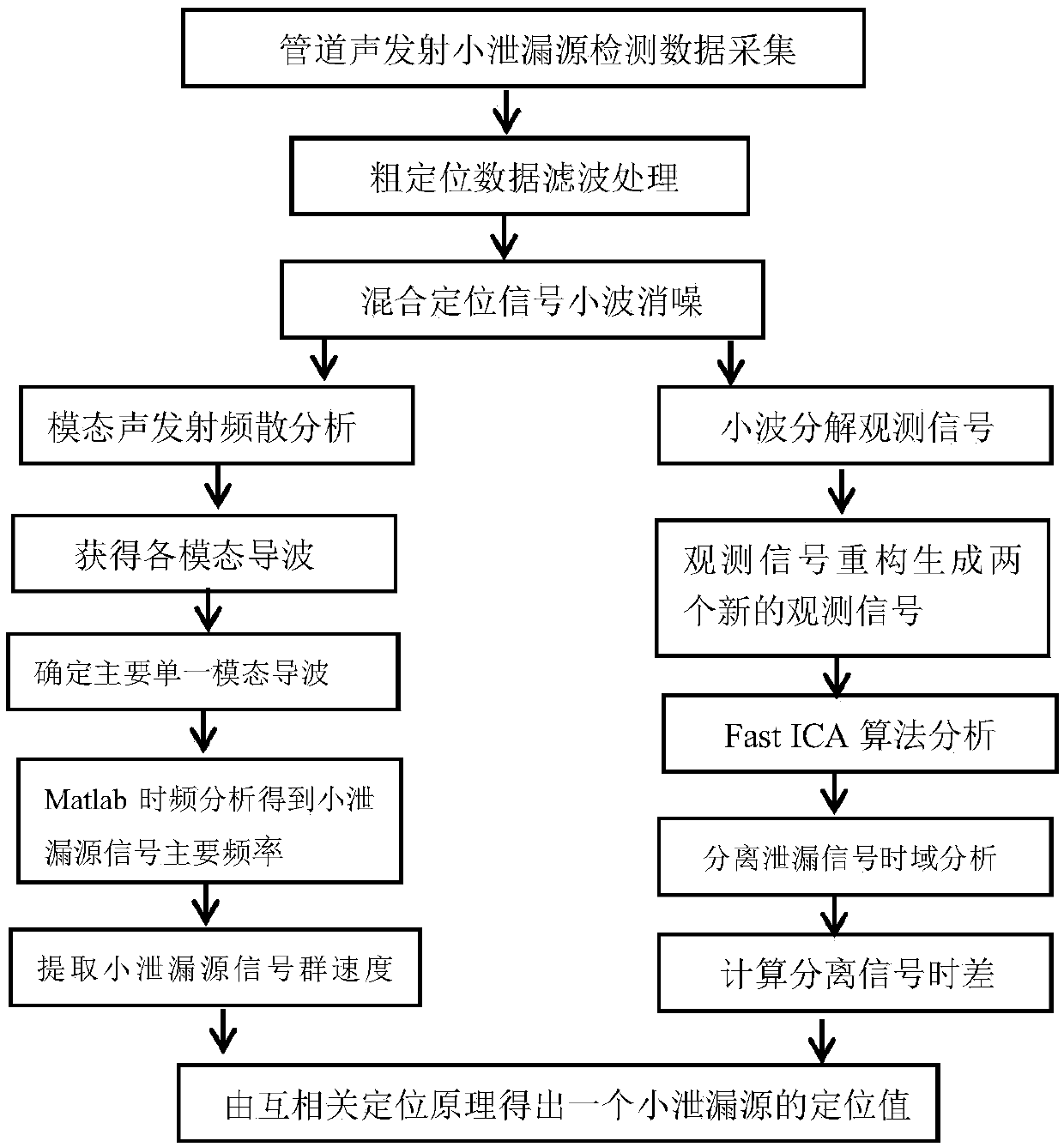

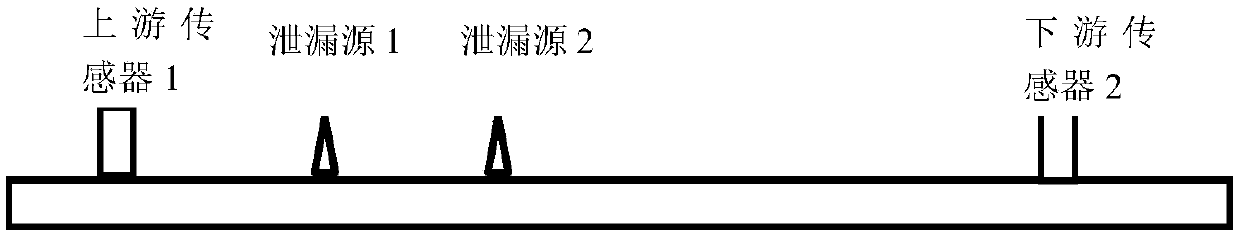

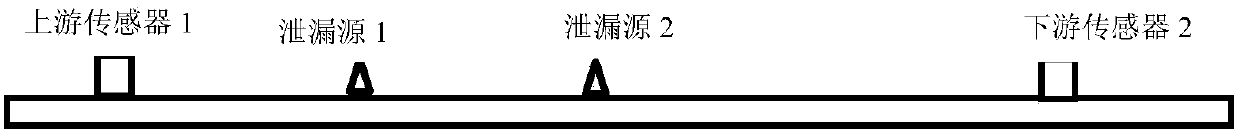

[0051] For the problem of mutual interference of small leakage source localization acoustic emission localization signals, under some specific assumptions, according to independent component analysis technology blind source separation theory, when the number of sensors is greater than or equal to the source signal, the source signal can be separated. According to this theory, the present invention locates the multi-point leakage source by adopting the cross-correlation positioning principle of pipeline acoustic emission leakage detection, and can effectively locate its different leakage positions. Therefore, combining the theory of acoustic emission with the theory of blind source separation, multiple leakage sources that have occurred or are occurring can be located.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com