Wheel hub type recognition device and wheel hub identifier tracing management system

A management system and identification device technology, applied in character and pattern recognition, collaborative devices, data processing applications, etc., can solve problems such as high preventive maintenance and related costs, inability to prevent and control equipment failures, and inefficiency. The effect of reducing preventive maintenance and related costs, realizing the integration of automation and information, and eliminating the need for consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

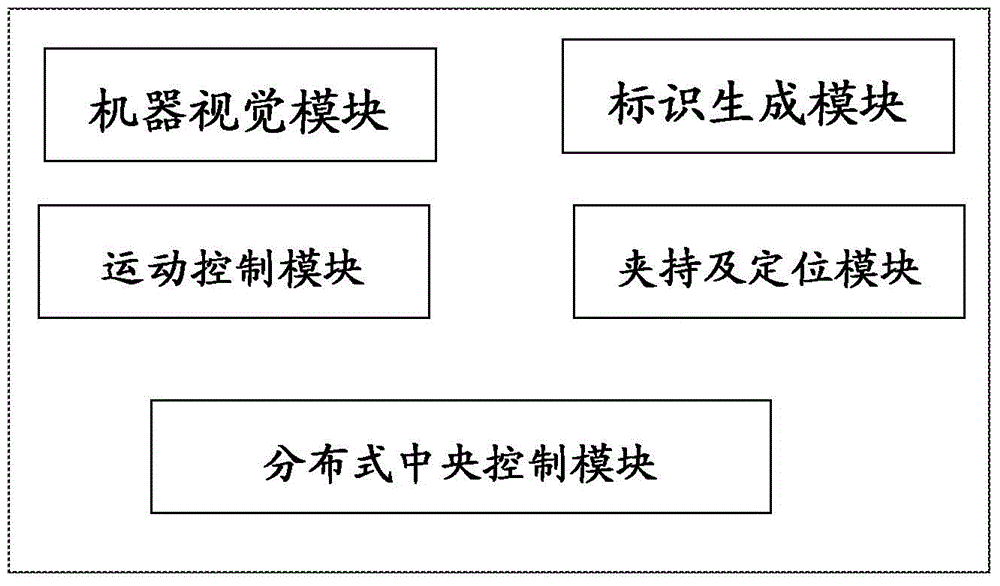

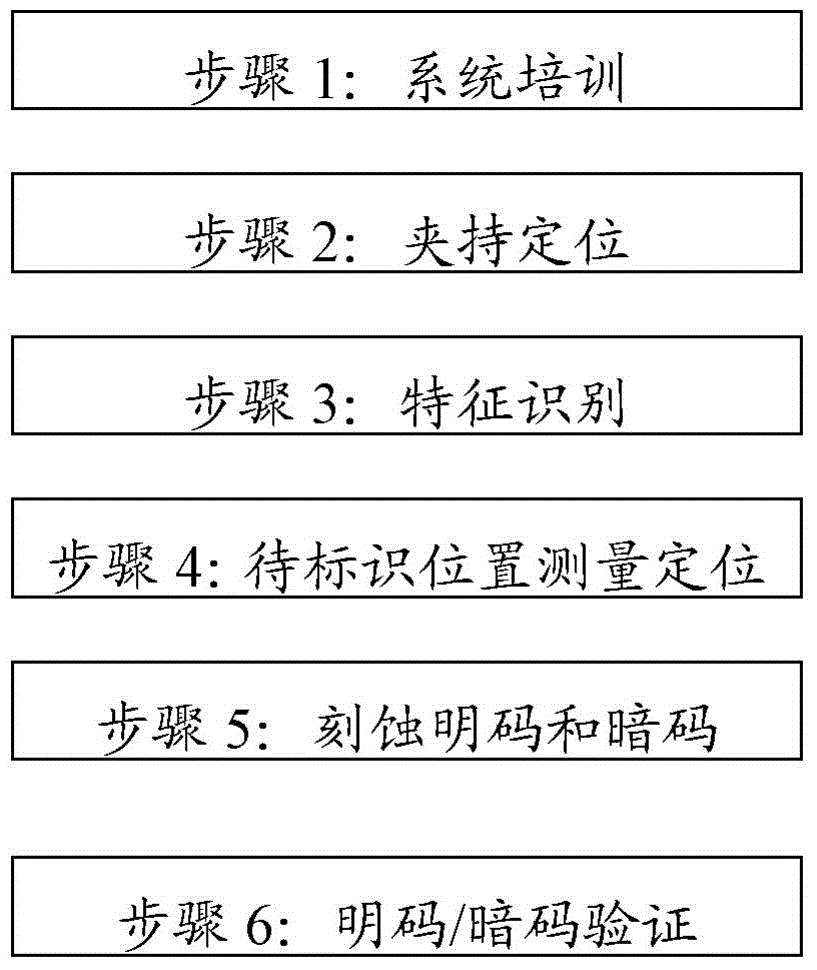

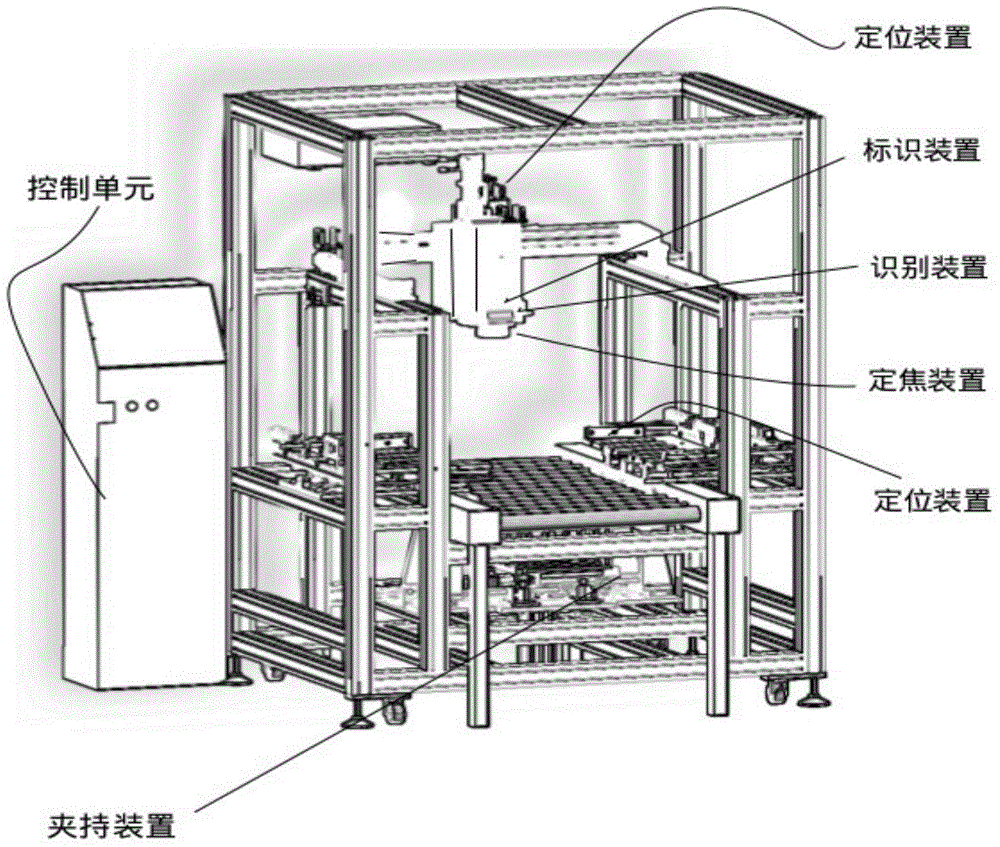

[0038] Hereinafter, preferred embodiments of the present invention are described in more detail with reference to the accompanying drawings so that those skilled in the art can easily implement the present invention. However, when it is considered that a detailed description of conventional functions and structures associated with the present invention may undesirably obscure the gist of the present invention, such detailed description is omitted. in, figure 1 It is a functional block diagram of the automobile wheel label traceability management system according to the present invention; figure 2 It is a work flow diagram of using the automobile wheel label traceability management system of the present invention to carry out wheel label; image 3 It is a structural schematic diagram of the automobile wheel label traceability management system according to the present invention.

[0039] First, refer to figure 1 To illustrate the main functions of the automobile wheel lab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com