Temperature-sensitive tag and application thereof

A sensitive and labeling technology, applied in identification devices, instruments, optics, etc., can solve the problems of uncontrollable temperature response, unreliable recording effect, and high cost of temperature monitoring devices, achieving reliable recording effect, controllable temperature response, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 150 μm thick polyethylene terephthalate (PET) film is used as the base material, and a layer of indium tin oxide (ITO) is plated on its surface by magnetron sputtering as a transparent conductive layer, and then magnetron sputtered Method Coating a layer of tungsten trioxide (WO 3 ) thin film, as the electrochromic active layer, thereby constituting the electrochromic electrode.

[0040] Another PET film coated with ITO was used as the counter electrode.

[0041] Use polyethylene glycol (PEG400, melting point -3°C) with a molecular weight of 400 dissolved in 0.1 mol / L lithium bistrifluoromethanesulfonimide (LiTFSI) as the electrolyte, and use it to infiltrate the glass fiber separator to prepare the electrolyte layer.

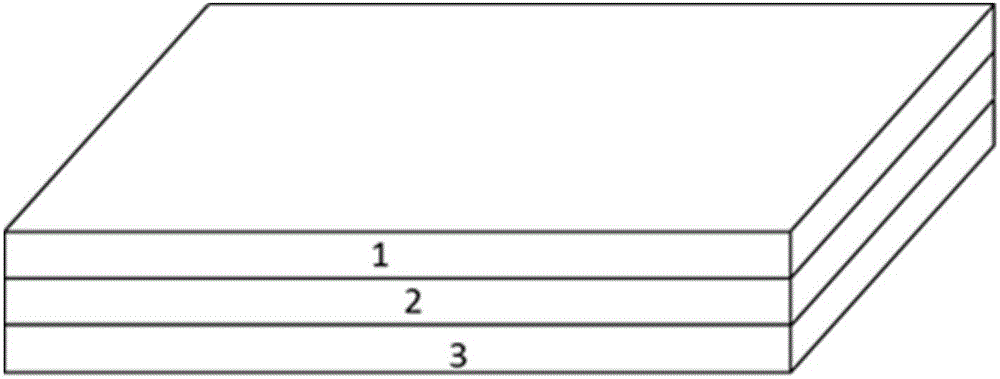

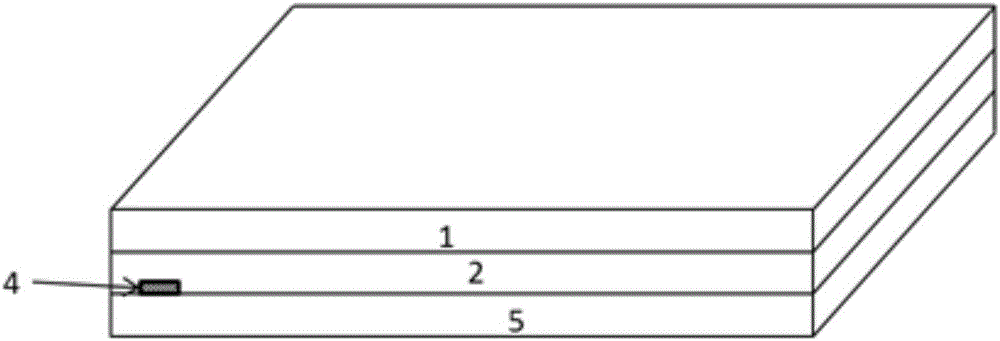

[0042] Cut the three layers of material into 2cm x 1cm squares and stack them together, as shown in the instruction manual figure 1 shown.

[0043] At a room temperature of 27°C, apply a voltage of 3.2V between the electrochromic electrode and the ...

Embodiment 2

[0045] If the PEG400 in Example 1 is changed to PEG600, the melting point of the electrolyte becomes 20°C, and the label can indicate whether the item has experienced a process higher than 20°C.

Embodiment 3

[0047] The concentration of LiTFSI in Example 1 was reduced to 0.001mol / l, the electrolyte diaphragm was changed to plant fiber paper, and the rest remained unchanged. Then, when the electrochromic electrode was in a dark blue state, at room temperature, the applied voltage was removed, and the electrochromic electrode was turned off. The time required for the chromic electrode to turn back to pale yellow was changed to 20 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com