Pumping speed limiting method and device in fabrication of negative electrode of photomultiplier

A technology for photomultiplier tubes and cathodes, which is applied to electrode devices of multiple dynodes, manufacturing of light-emitting cathodes, manufacturing of secondary emitter electrodes, etc., can solve the problems of high price and difficult cleaning, and achieves convenient operation, low cost, and low cost. Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below with reference to accompanying drawing and embodiment:

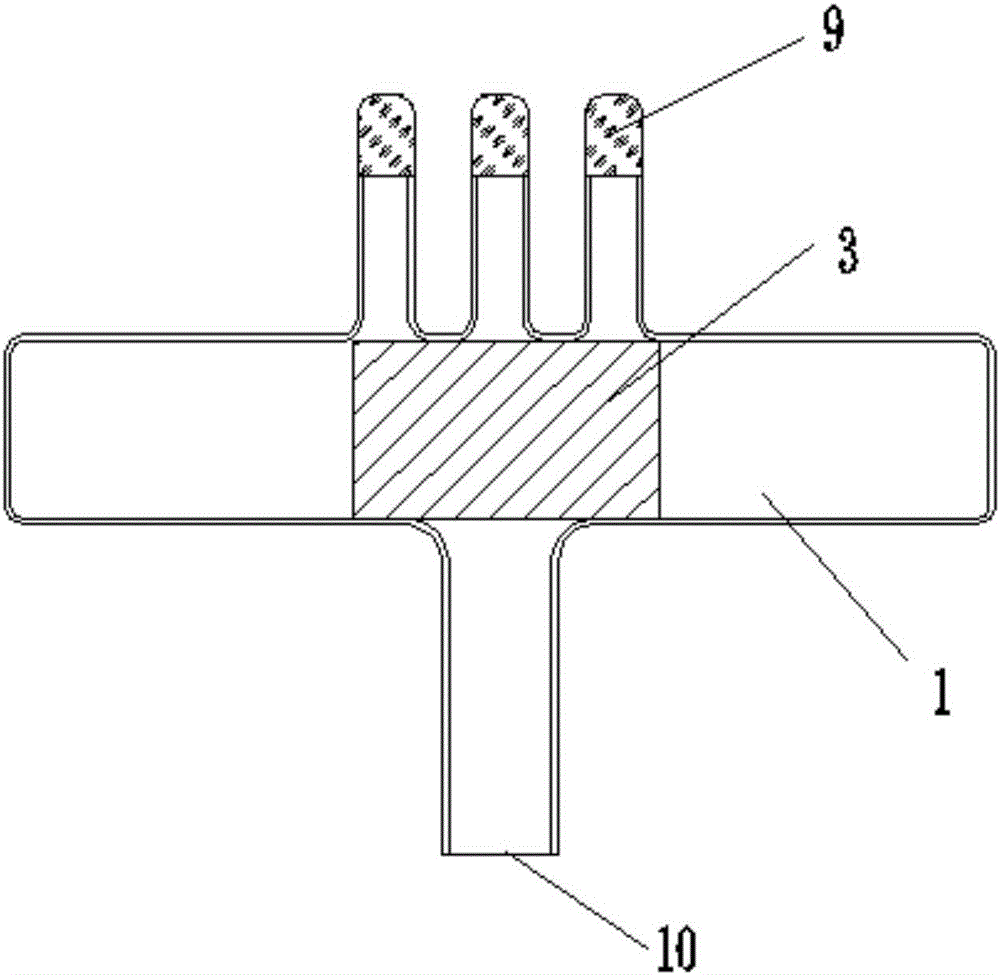

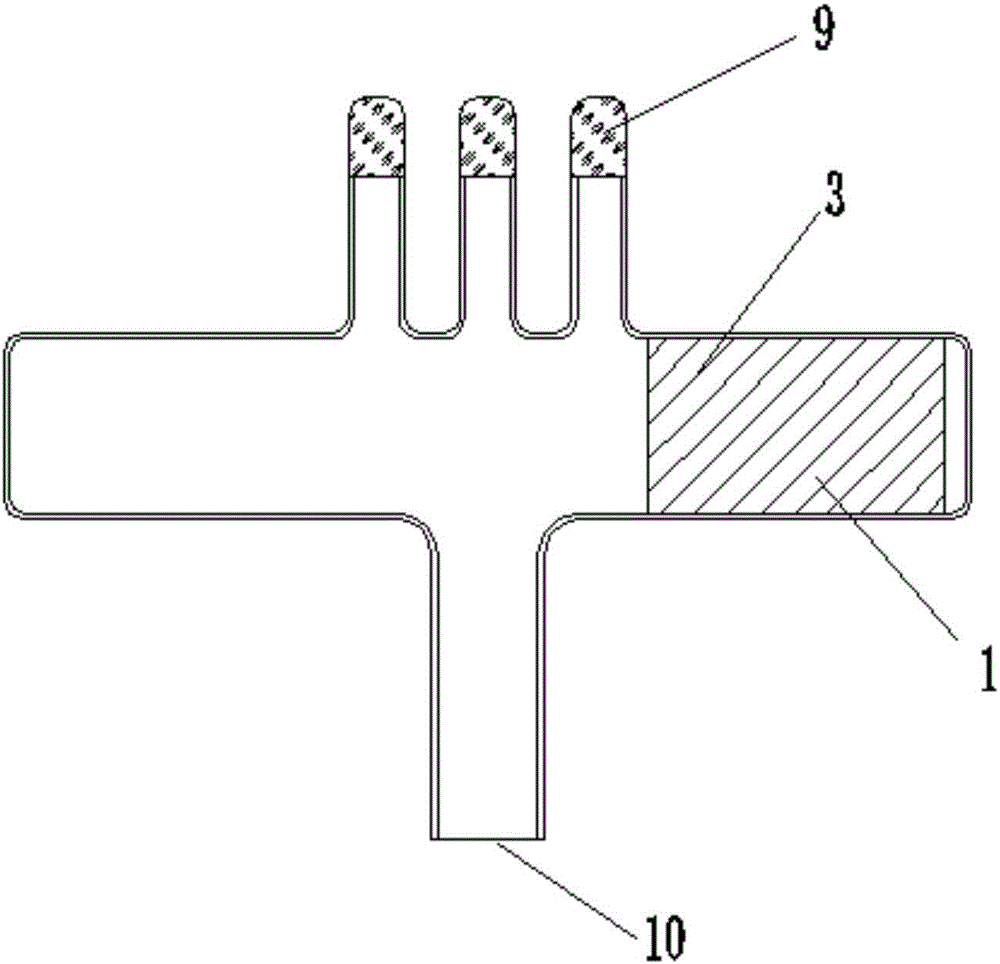

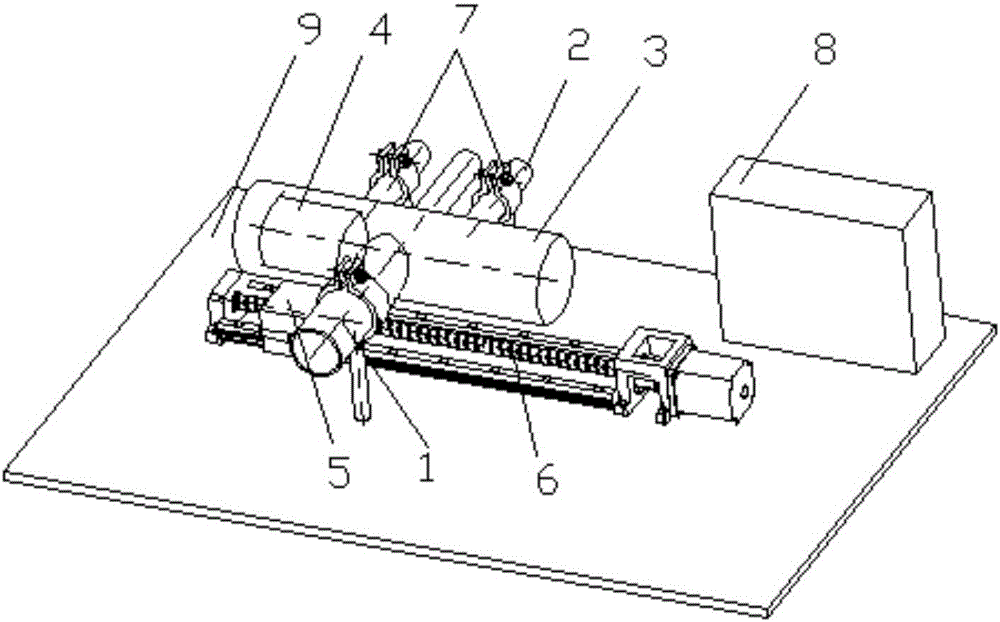

[0038] attached Figure 1-3 It can be seen that a limiting pumping speed device in the manufacture of the cathode of a photomultiplier tube comprises: a photomultiplier tube 9 and a vacuum tube 1, the photomultiplier tube is connected with one end of the vacuum tube 1 through a connecting tube 2; the other end of the vacuum tube 1 is connected to the vacuum tube 1 The devices are connected; a horizontal glass tube 3 is arranged between the connecting pipe 2 and the vacuum tube 1; the axis of the horizontal glass tube 3 is perpendicular to the axis of the vacuum tube 1; the horizontal glass tube 3 is provided with an air inlet for sealing the vacuum tube 1 The slider 4; the outside of the transverse glass tube 3 is provided with an electromagnet 5.

[0039] The diameter of the transverse glass tube is 20mm.

[0040] The slide block is a columnar slide block; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com