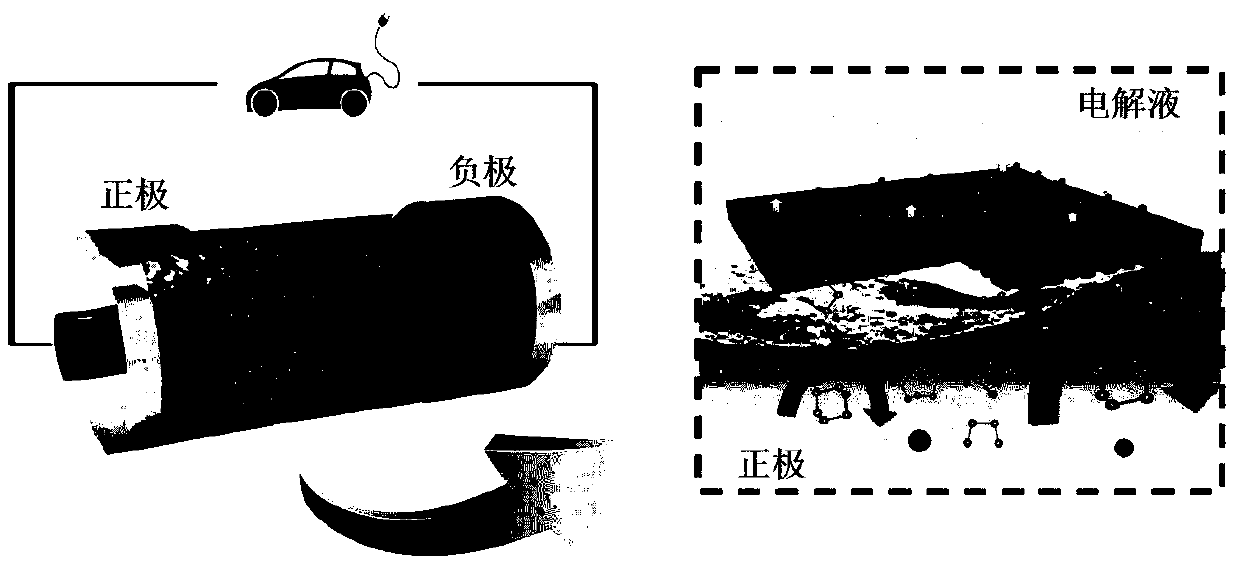

A method for constructing a stable solid-state interface on the cathode surface of sulfur-based and selenium-based batteries

A battery positive electrode, selenium-based technology, applied in secondary batteries, secondary battery repair/maintenance, secondary battery charging/discharging, etc., can solve battery capacity and coulombic efficiency decline, cycle life and coulombic efficiency decay Enough electrochemically active interface and other issues to achieve the effect of promoting cycle stability and improving charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the method for constructing a stable solid-state interface on the positive electrode surface of sulfur-based and selenium-based batteries includes the following steps:

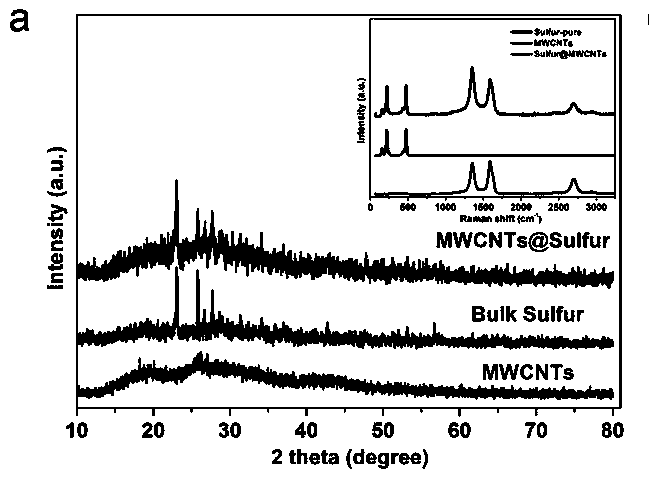

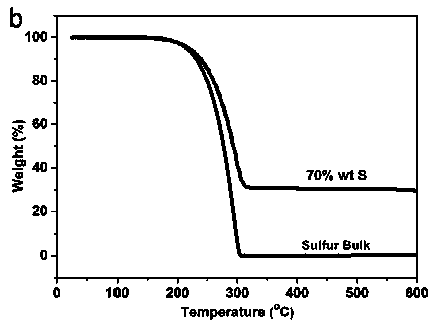

[0030] 1) Preparation of positive electrode material: the active material in the positive electrode material is elemental sulfur or selenium or sulfide or selenide; the positive electrode material can also contain conductive substances or substances with chemical polarization, and the conductive substance can be carbon materials , metal oxides or conductive polymers, substances with chemical polarization can use C 3 N 4 . The method for preparing the positive electrode material in this example is as follows: a. The multi-walled carbon nanotubes and the sulfur element are uniformly mixed according to the mass ratio of 3:7; b. The obtained sulfur-containing mixture is put into a closed container, and heated for 12 Hours; c. The electrode material after dissolving sulfur, carbon black...

Embodiment 2

[0037] In this embodiment, the method for constructing a stable solid-state interface on the positive electrode surface of sulfur-based and selenium-based batteries includes the following steps:

[0038] 1) Preparation of positive electrode material: the active material in the positive electrode material is elemental sulfur or selenium or sulfide or selenide; the positive electrode material can also contain conductive substances or substances with chemical polarization, and the conductive substance can be carbon materials , metal oxides or conductive polymers, substances with chemical polarization can use C 3 N 4 . The method for preparing the positive electrode material in this example is as follows: a. The multi-walled carbon nanotubes and the sulfur element are uniformly mixed according to the mass ratio of 3:7; b. The obtained sulfur-containing mixture is put into a closed container, and heated for 12 Hours; c. The electrode material after dissolving sulfur, carbon black...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com