Image sensor and manufacturing method thereof

An image sensor and wafer technology, applied in the field of image sensors, can solve problems such as poor performance of CMOS image sensors, and achieve the effects of improving quantum conversion efficiency, good absorption, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

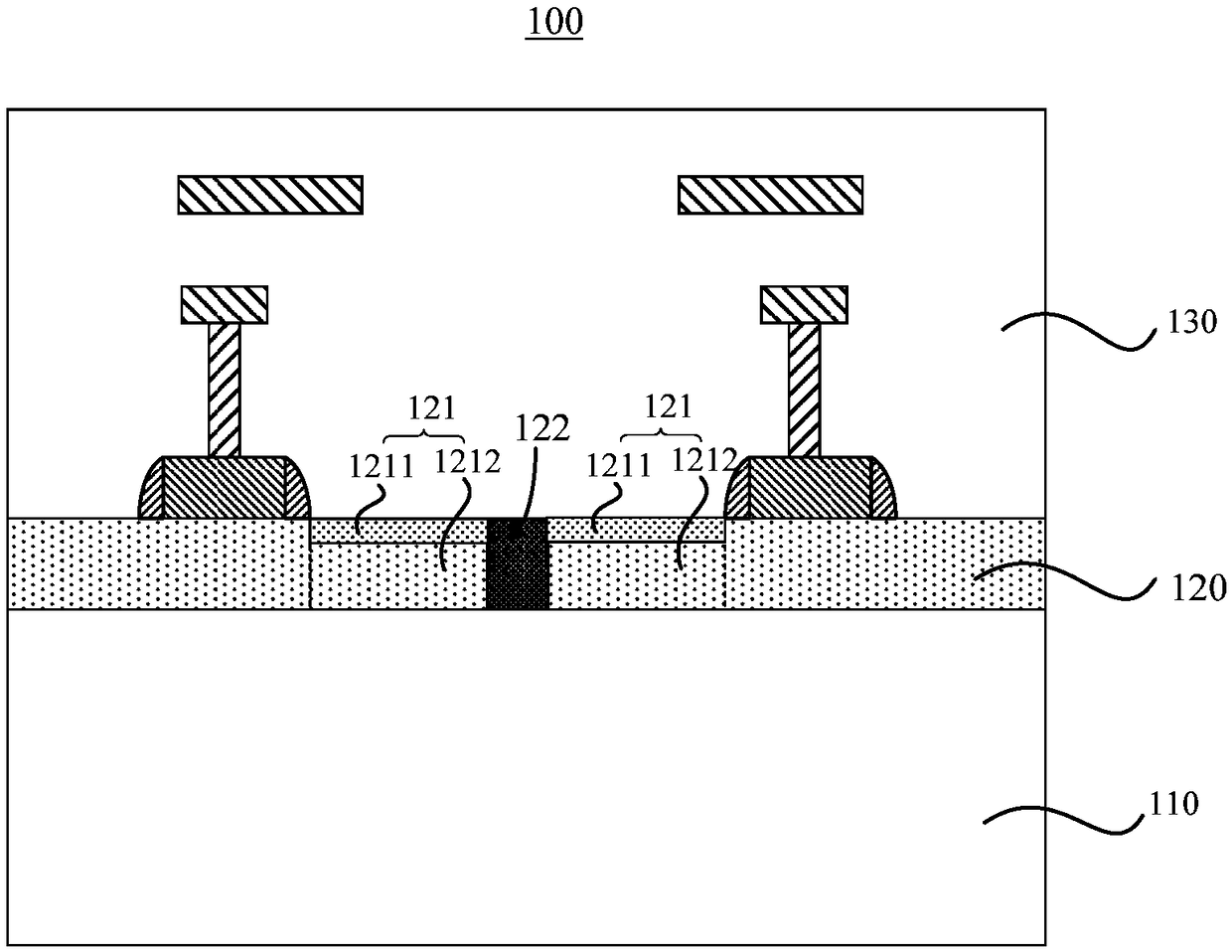

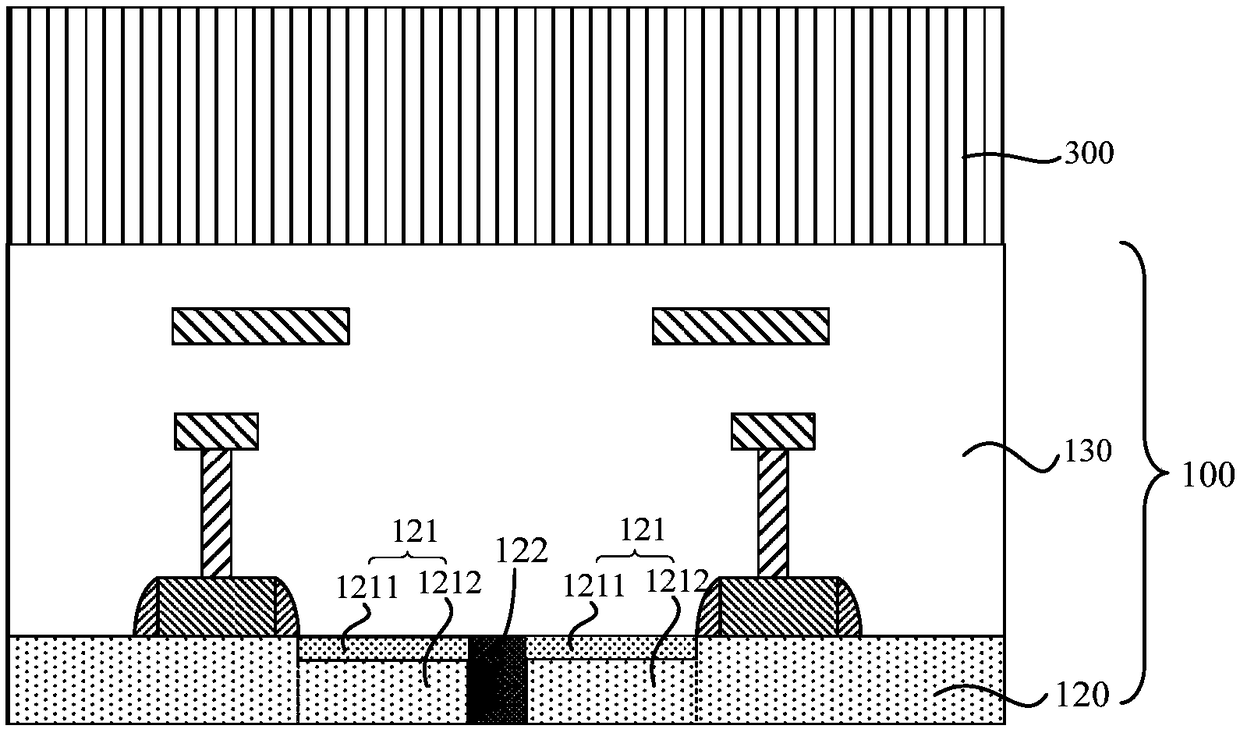

preparation example Construction

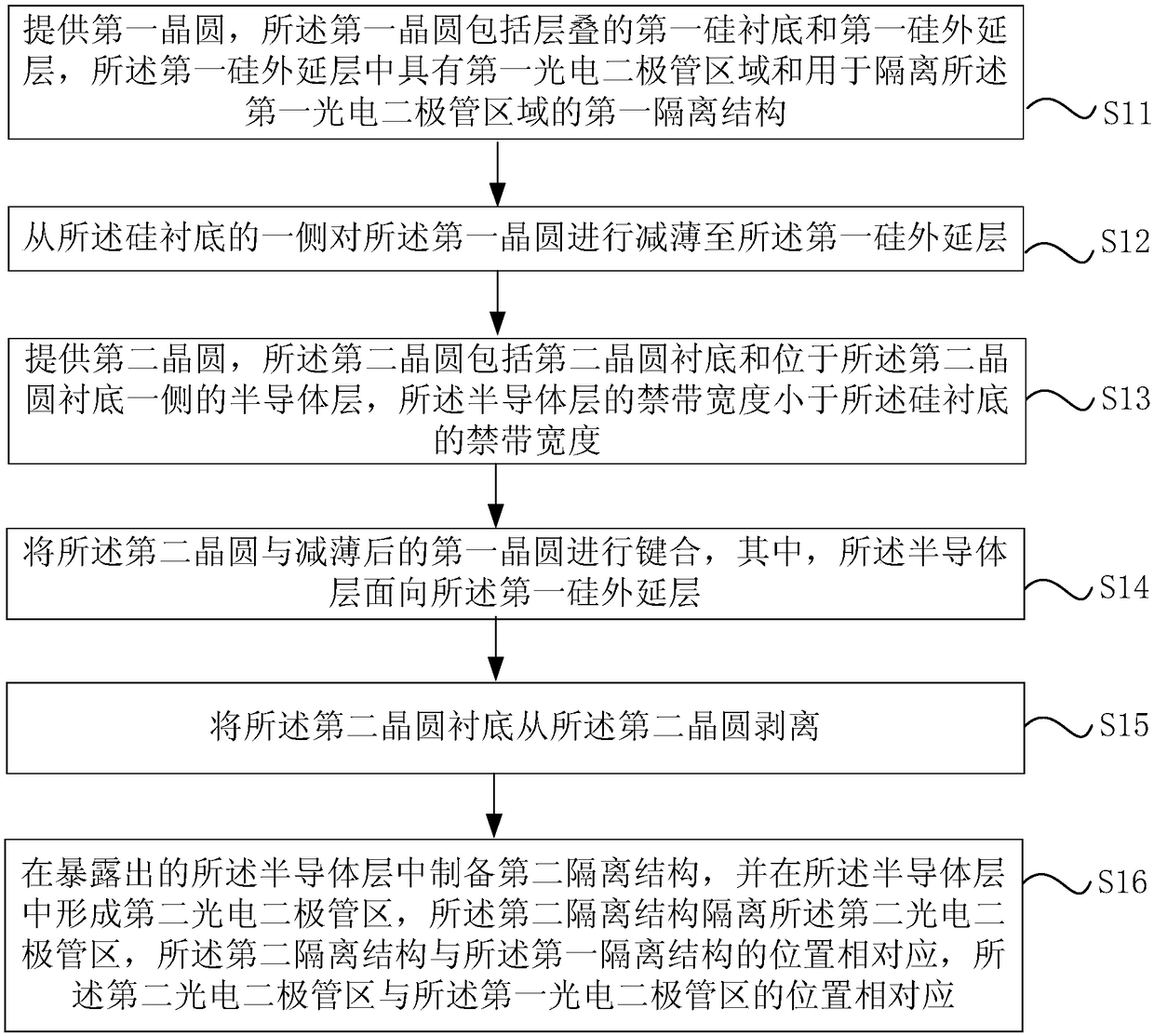

[0038] According to the above research, the present invention provides a method for preparing an image sensor, providing a method for preparing an image sensor, such as figure 1 shown, including the following steps:

[0039] Step S11, providing a first wafer, the first wafer includes a stacked first silicon substrate and a first silicon epitaxial layer, the first silicon epitaxial layer has a first photodiode region and is used to isolate the a first isolation structure for the first photodiode region;

[0040] Step S12, thinning the first wafer to the first silicon epitaxial layer from one side of the silicon substrate;

[0041] Step S13, providing a second wafer, the second wafer includes a second wafer substrate and a semiconductor layer on one side of the second wafer substrate, the semiconductor layer has a band gap smaller than that of the silicon The bandgap width of the substrate;

[0042] Step S14, bonding the second wafer to the thinned first wafer, wherein the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com