Manufacturing method for perovskite solar cell with compound electronic transmission layer structure

A technology for solar cells and electron transport layers, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

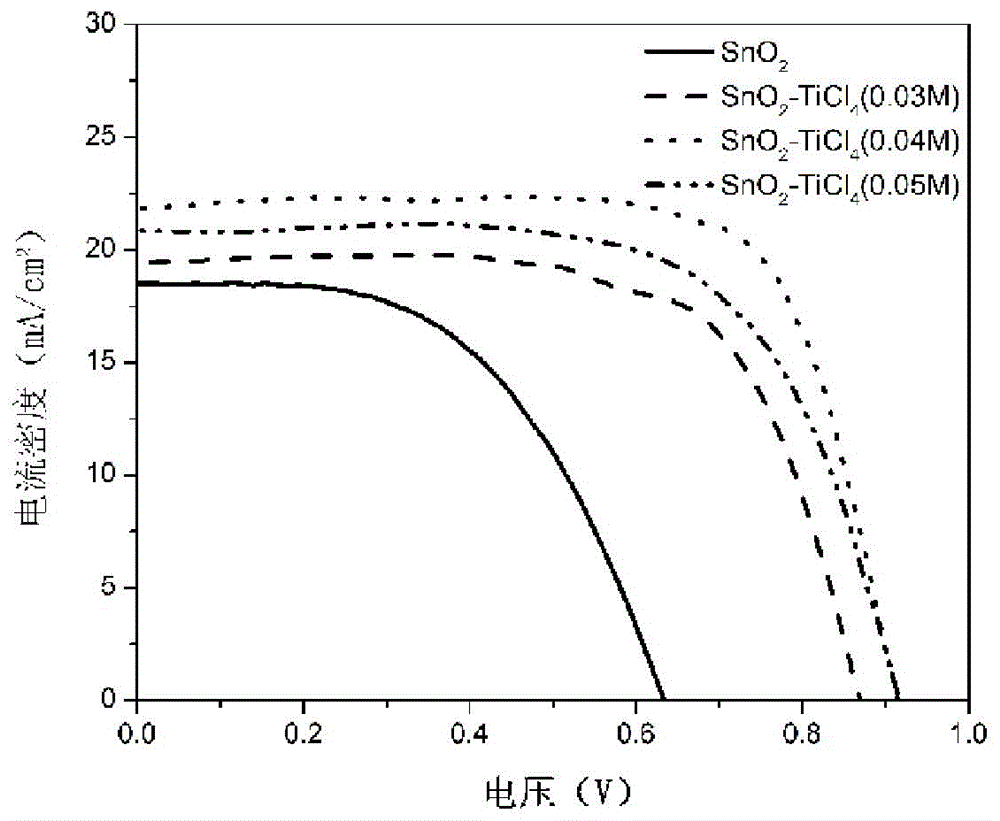

Image

Examples

Embodiment 1

[0024] The conductive glass layer, the composite electron transport layer, the perovskite polycrystalline film, the hole transport material layer and the evaporated silver electrode layer are arranged in sequence. The structure effectively conducts electrons, the conductive glass layer is used as the substrate of the perovskite solar cell, and the energy levels of the perovskite polycrystalline film, the hole transport material layer and the evaporated silver electrode layer are matched, which can effectively conduct photoelectrons.

[0025] Preferably, the perovskite polycrystalline film is made of methylamine lead iodine polycrystalline film. The synthesis and preparation of methylamine lead iodine polycrystalline film in perovskite polycrystalline film is relatively mature and simple. At the same time, the stability in air is relatively high, and the cost is low, which is conducive to mass production.

[0026] Preferably, spiro-OMeTAD is selected as the hole transport mater...

Embodiment 2

[0035] The conductive glass layer, the composite electron transport layer, the perovskite polycrystalline film, the hole transport material layer and the evaporated silver electrode layer are arranged in sequence. The structure effectively conducts electrons, the conductive glass layer is used as the substrate of the perovskite solar cell, and the energy levels of the perovskite polycrystalline film, the hole transport material layer and the evaporated silver electrode layer are matched, which can effectively conduct photoelectrons.

[0036] Preferably, the perovskite polycrystalline film is made of methylamine lead iodine polycrystalline film. The synthesis and preparation of methylamine lead iodine polycrystalline film in perovskite polycrystalline film is relatively mature and simple. At the same time, the stability in air is relatively high, and the cost is low, which is conducive to mass production.

[0037] Preferably, spiro-OMeTAD is selected as the hole transport mater...

Embodiment 3

[0046] The conductive glass layer, the composite electron transport layer, the perovskite polycrystalline film, the hole transport material layer and the evaporated silver electrode layer are arranged in sequence. The structure effectively conducts electrons, the conductive glass layer is used as the substrate of the perovskite solar cell, and the energy levels of the perovskite polycrystalline film, the hole transport material layer and the evaporated silver electrode layer are matched, which can effectively conduct photoelectrons.

[0047] Preferably, the perovskite polycrystalline film is made of methylamine lead iodine polycrystalline film. The synthesis and preparation of methylamine lead iodine polycrystalline film in perovskite polycrystalline film is relatively mature and simple. At the same time, the stability in air is relatively high, and the cost is low, which is conducive to mass production.

[0048] Preferably, spiro-OMeTAD is selected as the hole transport mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com