Electronic system self-radiating structure

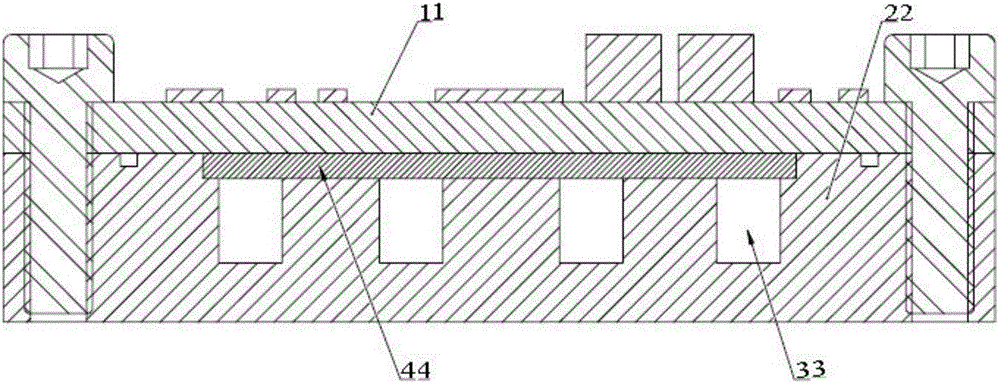

An electronic system and self-heating technology, which is applied to the structural parts of electrical equipment, electrical components, cooling/ventilation/heating renovation, etc., can solve the problems of the electronic system cooling plate 44 being unable to fit closely, affecting the thermal coupling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

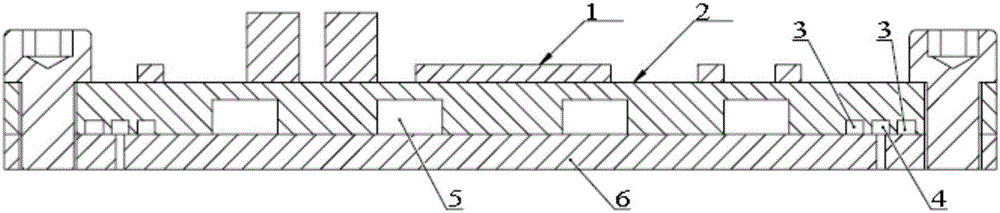

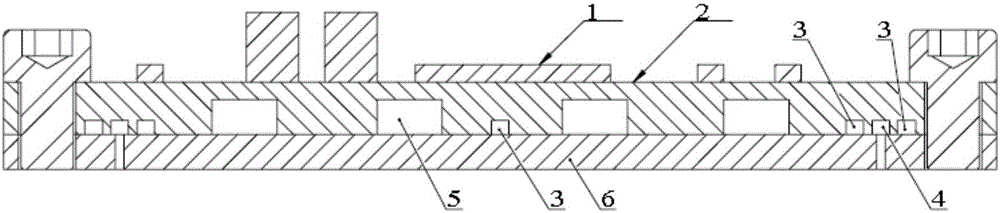

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0019] Such as figure 2 As shown, the present invention discloses a self-dissipating structure of an electronic system. A heat dissipation medium groove is processed on the electronic system substrate and filled with a circulating heat dissipation medium. The heat dissipation medium flows inside the electronic system and directly contacts the electronic system, providing Good cooling efficiency.

[0020] Among them, the electronic system 2 adopts a metal substrate. On the one hand, the thermal conductivity of the metal substrate is larger than that of the polymer substrate, and the thermal conductivity is better. seal. The thickness of the metal substrate depends on the strength of the substrate and the pressure of the cooling medium. It is recommended that the thickness of the metal substrate be greater than 4mm. Wiring on the upper surface of the metal sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com