A method for accelerating the pickling of meat products using ultra-high pressure combined with protease

A protease and ultra-high pressure technology, which is applied in the field of food processing, can solve the problems of prolonging the storage period of cured meat products, high salt content in the pickling solution, and shortening the curing time, so as to shorten the curing time, reduce the amount of salt added, The effect of arranging the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Take the goose breast out of the refrigerator, defrost naturally, wash and cut into 6×6×2cm 3 blocky in size.

[0033] (2) According to the mass ratio of the solution and the meat piece, the papain solution with a concentration of 0.9mg / mL is evenly injected into the goose breast in the ratio of 1:100, then the goose breast is placed in a vacuum packaging bag, and Pour the pickling solution containing 5% salt in the vacuum packaging bag (the mass ratio of goose breast meat to the pickling solution is 1:3), and vacuum pack. Wherein, the solution for dissolving papain is a phosphate buffer solution with a concentration of 0.1 mol / L and a pH of 7.0.

[0034] (3) Place the packaged goose breast meat in an ultra-high pressure device for ultra-high pressure treatment, the pressure is 400MPa, and the time is 3min.

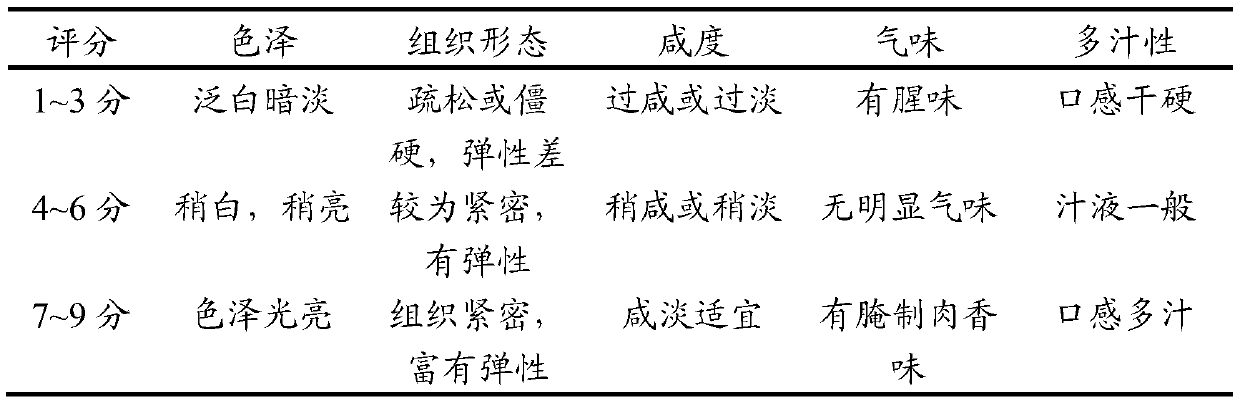

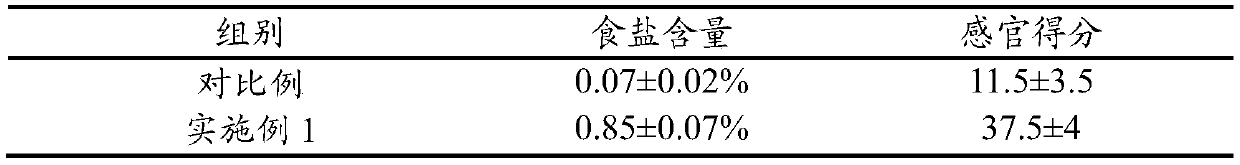

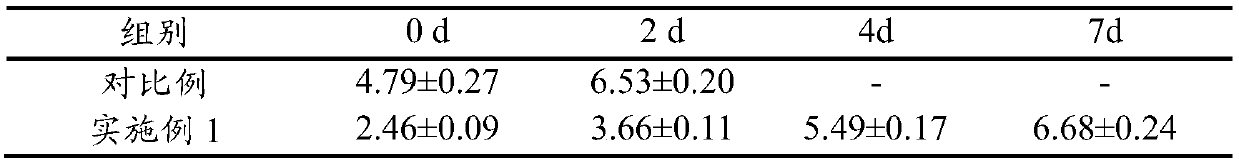

[0035] Effect test

[0036] The goose breast meat product in Example 1 is compared with the product obtained through the traditional pickling process. Under...

Embodiment 2

[0047](1) Take the beef out of the refrigerator, defrost naturally, wash and cut into 10×10×5cm 3 blocky in size.

[0048] (2) Evenly inject 0.8 mg / mL papain solution into the beef according to the mass ratio of the solution to the meat piece at a ratio of 1:110, place it in a vacuum packaging bag, and pour into the vacuum packaging bag containing The percentage concentration is the pickling solution of 9% table salt (the mass ratio of beef and pickling solution is 1:4), vacuum-pumped packing. Wherein, the solution for dissolving papain is a phosphate buffer solution with a concentration of 0.1 mol / L and a pH of 6.8.

[0049] (3) Put the packaged beef in an ultra-high pressure device for ultra-high pressure treatment, the pressure is 600MPa, and the time is 2min.

Embodiment 3

[0051] (1) Take the peeled rabbit meat out of the refrigerator, thaw it naturally, wash it, and cut it into 5×5×2cm 3 blocky in size.

[0052] (2) The bromelain solution of 1.5mg / mL is evenly injected into the rabbit meat according to the ratio of 1:120 by the mass ratio of the solution to the meat piece, placed in a vacuum packaging bag, and poured into the vacuum packaging bag containing The pickling solution (mass ratio of rabbit meat to pickling solution is 1:5) with a mass percent concentration of 12% salt is vacuum-packed. Wherein, the solution for dissolving bromelain is a phosphate buffer solution with a concentration of 0.1 mol / L and a pH of 7.2.

[0053] (3) Place the packaged rabbit meat in an ultra-high pressure device for ultra-high pressure treatment, the pressure is 300MPa, and the time is 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com