Method for enhancing preservation and tenderness of sliced dried beef

A preservative and beef jerky technology, which is applied in meat/fish preservation, food preservation, meat/fish preservation with chemicals, etc. It can solve the problems of high hardness, weak product market competitiveness, and monotonous flavor, and achieve hardness reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

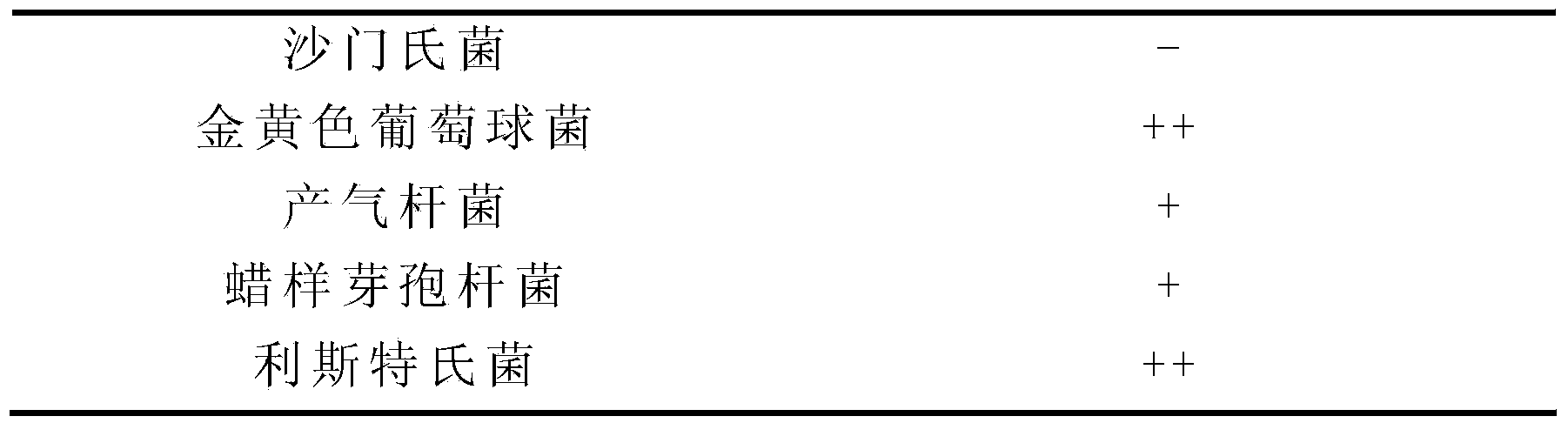

Embodiment 1

[0049] After the cattle are slaughtered and divided, the hind leg of the beef is selected as the raw material for processing, and the hind leg of the beef is divided into regular blocks with a weight of 2.5Kg. The cleaned beef block is pre-cooked at 100°C for 1 hour, cooled, and mechanically cut into beef with a thickness of 1.2cm. Slices, beef slices were boiled at 100°C for 5 minutes, taken out, drained, and weighed after cooling; add 4.5% salt, 2.5% sugar, 1.5% honey, 0.4% beef powder, chili powder according to the weight of the weighed beef slices 0.4%, 1.2% monosodium glutamate, 1.2% chicken essence, 0.12% maltol, 1.3% compound spices, 1.0% arowana oil, after rolling for 4 minutes, add 4% lactic acid bacteria-producing plant milk according to the weight of the weighed beef slices The fermented concentrate of Lact.chili.6, mixed evenly, sealed, and fermented at room temperature for 8 hours; the fermented beef slices were baked at 80°C for 4 hours until the water activity of...

Embodiment 2

[0053] After the cattle are slaughtered and divided, the hind leg of the beef is selected as the raw material for processing, and the hind leg of the beef is divided into regular blocks with a weight of 3.0Kg. The cleaned beef block is pre-cooked at 100°C for 1.2 hours, cooled, and mechanically cut into 1.5cm thick pieces. Beef slices, boil the beef slices at 100°C for 5 minutes, take them out, drain, and weigh after cooling; add 5% salt, 3.5% sugar, 2.0% honey, 0.35% beef powder, and chili pepper according to the weight of the weighed beef slices. 0.45% powder, 1.0% monosodium glutamate, 1% chicken essence, 0.1% maltol, 1.2% compound spices, 1.0% arowana oil, after rolling for 6 minutes, add 5% lactic acid bacteria-producing plants according to the weight of the weighed beef slices The fermented concentrate of Lactobacillus Lact.chili.6, mixed evenly, sealed, and fermented at room temperature for 8 hours; the fermented beef slices were baked at 90°C for 3 hours until the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com