Hydrocolloid adhesive, related application and hydrocolloid dressing

A hydrocolloid and adhesive technology, applied in adhesive dressings, dressings, medical sciences, etc., can solve the problems of poor clinical effect and lack of absorption, and achieve a solution that is conducive to early recovery, maintains a happy mood, and has low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

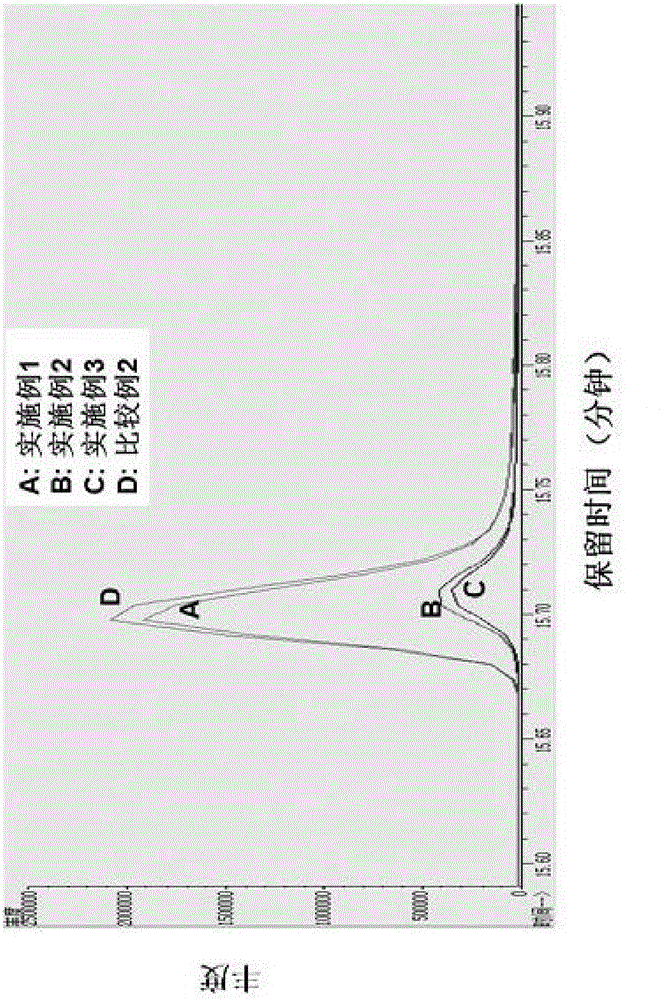

Image

Examples

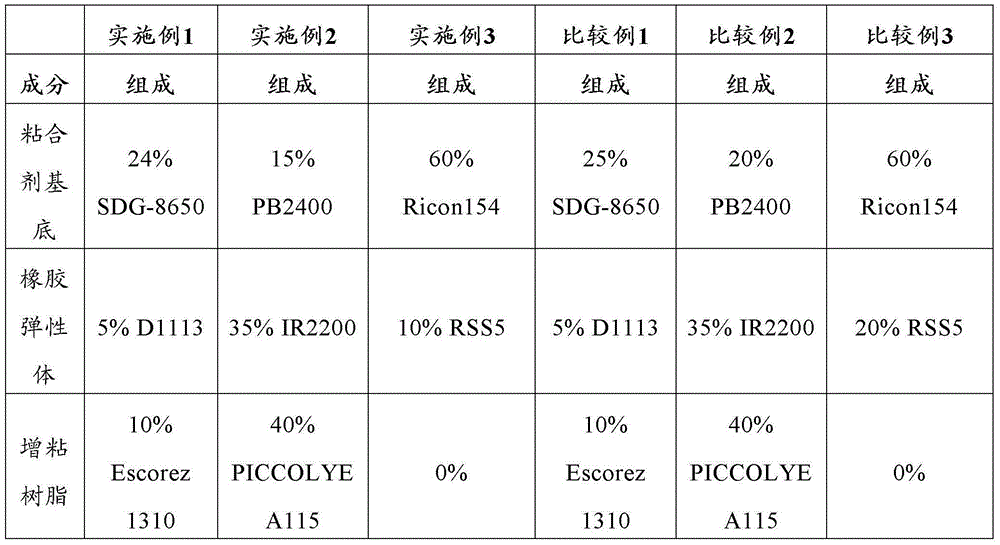

Embodiment 1-3、 comparative example 1-3

[0035]The adhesive base, rubber elastic body, and tackifying resin were put into a mixer (Rheomix 3000 Mixer from Thermofisher Company) according to the composition ratio in Table 1, and mixed at 160° C. and 40 rpm for 20 minutes. Then put zinc ricinoleate and hydrophilic polymer into the mixer according to the composition ratio in Table 1, and mix for 20 minutes at 120° C. and 30 rpm. Remove the mixture to a liner and cool to room temperature.

[0036] Among them, the adhesive substrate is SDG-8650 polyisobutylene from Hangzhou Shunda Plastic Co., Ltd. (China), PB2400 polybutene from Korea Daelim Company, and Ricon154 polybutadiene from Crayville (Guangzhou) Chemical Co., Ltd.;

[0037] The rubber elastic body is D1113 poly(styrene / isoprene / styrene) of Kraton Company, IR2200 polyisoprene of Zeon Company, and RSS5 natural rubber of Sinochem International Co., Ltd.;

[0038] Tackifying resin is Escorez 1310 tackifying resin of Exxon Mobil Corporation, PICCOLYEA115 of Hercules ...

Embodiment 4

[0044] Embodiment 4 is to the peel strength test of steel plate

[0045] Using a manual tablet press, the hydrocolloid adhesive prepared in Examples 1-3 and Comparative Examples 1-3 is pressed into a sheet with a thickness of 0.5 mm, and subsequently compounded with a polyurethane film with a thickness of 25 microns to obtain a hydrocolloid Dressing test samples.

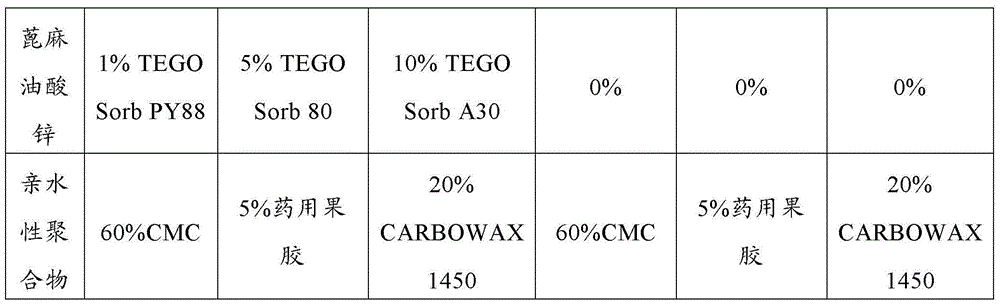

[0046] The hydrocolloid dressing test sample was cut into 25.4mm wide splines, the reinforced tape was laminated on the surface of the polyurethane film, and then the adhesive surface was laminated on the stainless steel plate. Use a pressing roller with a weight of 450 g to roll the sample back and forth once at a speed of 150 cm / min. After the sample was left to stand for 1 minute, it was tested using a tensile machine at a speed of 300mm / min and a peeling angle of 90°. The results are shown in Table 2. The test results showed that the addition of zinc ricinoleate did not significantly affect the tack of the hyd...

Embodiment 5

[0047] Embodiment 5 water absorption test

[0048] Take a 50mL glass reagent bottle with a cap diameter of 5.5cm, stick double-sided tape on the inside of the cap, and add 30mL of 0.9% NaCl solution into the bottle. The hydrocolloid dressing test sample (prepared according to the method in Example 4) was cut into a disc of the same size as the bottle cap, and weighed as W1. Stick the polyurethane film surface of the test sample on the inner side of the bottle cap, tighten the bottle cap and place the reagent bottle upside down in an oven at 37 degrees Celsius for 24 hours. The test sample was removed from the cap and weighed again as W2. The water absorption is calculated according to the following formula: water absorption (g / m 2 / 24h)=(W2-W1) / 0.002375, the results are shown in Table 2. The test results showed that the addition of zinc ricinoleate did not significantly affect the water absorption of the hydrocolloid adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com