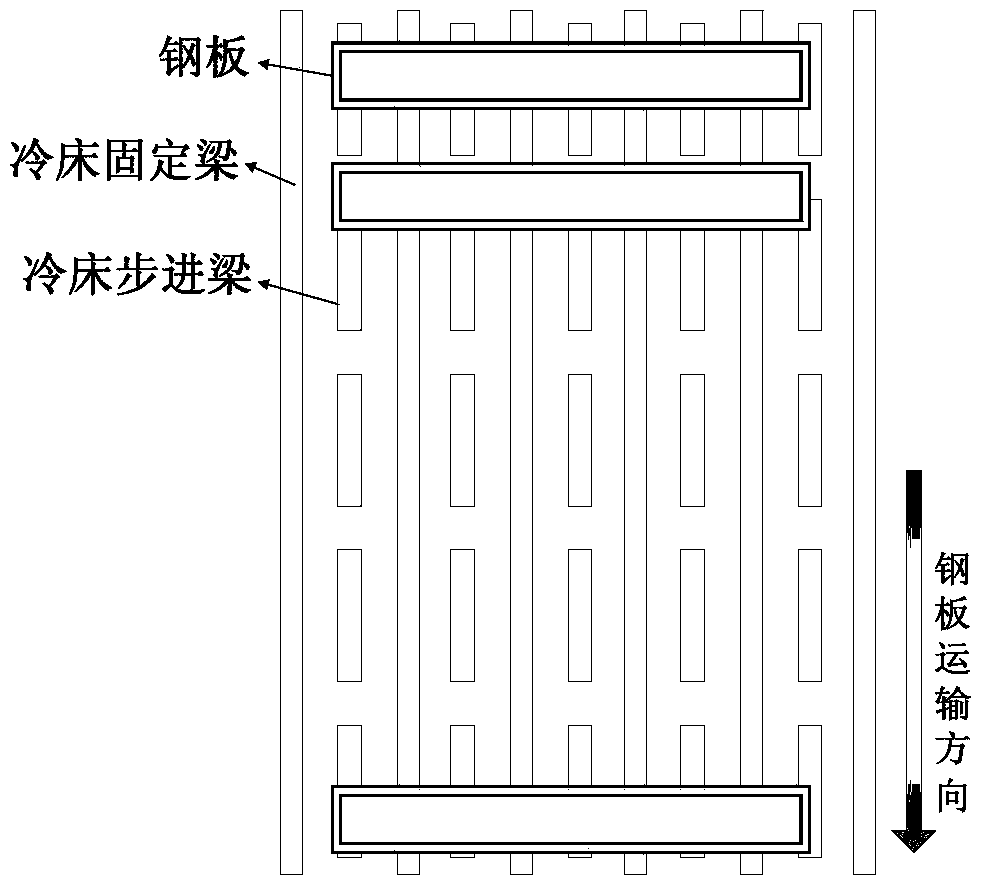

A method of independent partition control suitable for roller-disk cooling bed

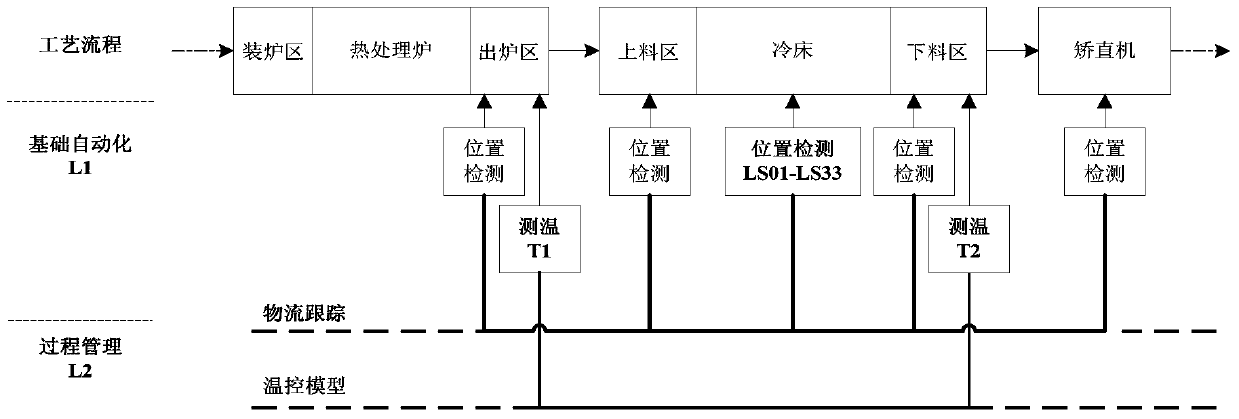

A partition control and cooling bed technology, applied in the field of control, can solve problems such as single transportation direction, uncontrollable cooling temperature, and inability to partition operation, etc., and achieve good ventilation performance, enhanced utilization rate, control flexibility, and compact equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

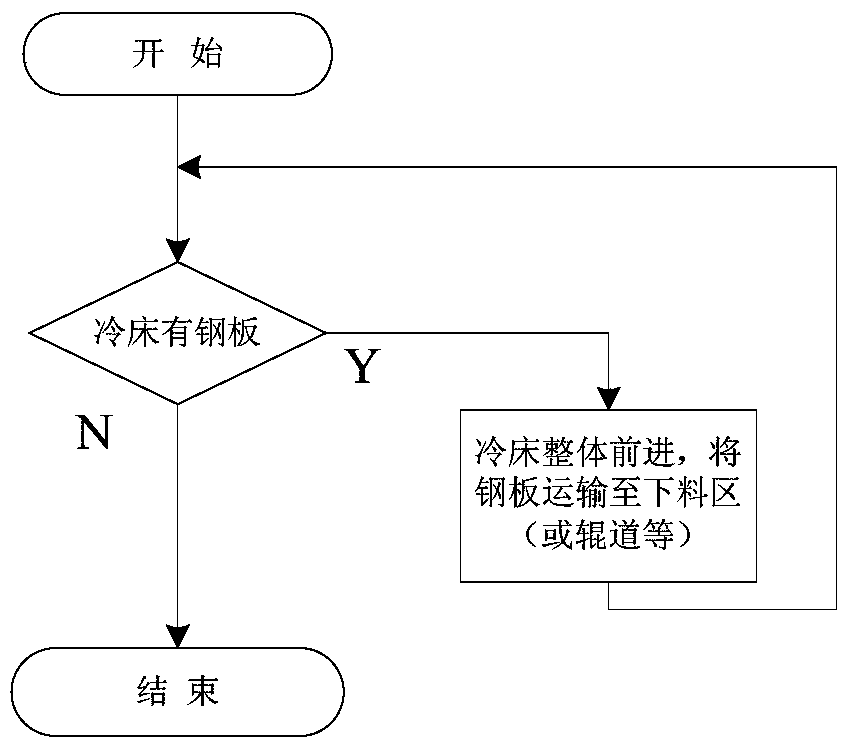

Method used

Image

Examples

Embodiment

[0089] Example: Steel plates of three specifications are produced by heat treatment. The specifications, initial temperature out of the furnace, target cooling temperature and cooling time set by the lower cooling bed are:

[0090]

[0091] According to the aforementioned steel plate temperature control model (also known as the air-cooling model), it can be seen that the cooling time required for three different specifications of steel plates A, B, and C on the cooling bed is not equal, and the relationship is satisfied: t 1 2 3 . Therefore, when using this technical solution, steel plates of three different specifications can be placed in different areas for independent cooling according to the aforementioned control flow chart.

[0092] 1. The transportation control of steel plate A on the independent partition cooling bed:

[0093] 1) When the first steel plate A completely enters the first area, it is judged that the specification of the next steel plate is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com