Double-face polishing machine for large-caliber optical element

A technology for double-sided polishing machines and optical components, which is applied in surface polishing machine tools, optical surface grinders, grinding/polishing equipment, etc. To meet the requirements of double-sided polishing of optical components and other issues, to achieve the effect of improving double-sided polishing accuracy and production efficiency, improving service life and system beam quality, and increasing adjustable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is further described.

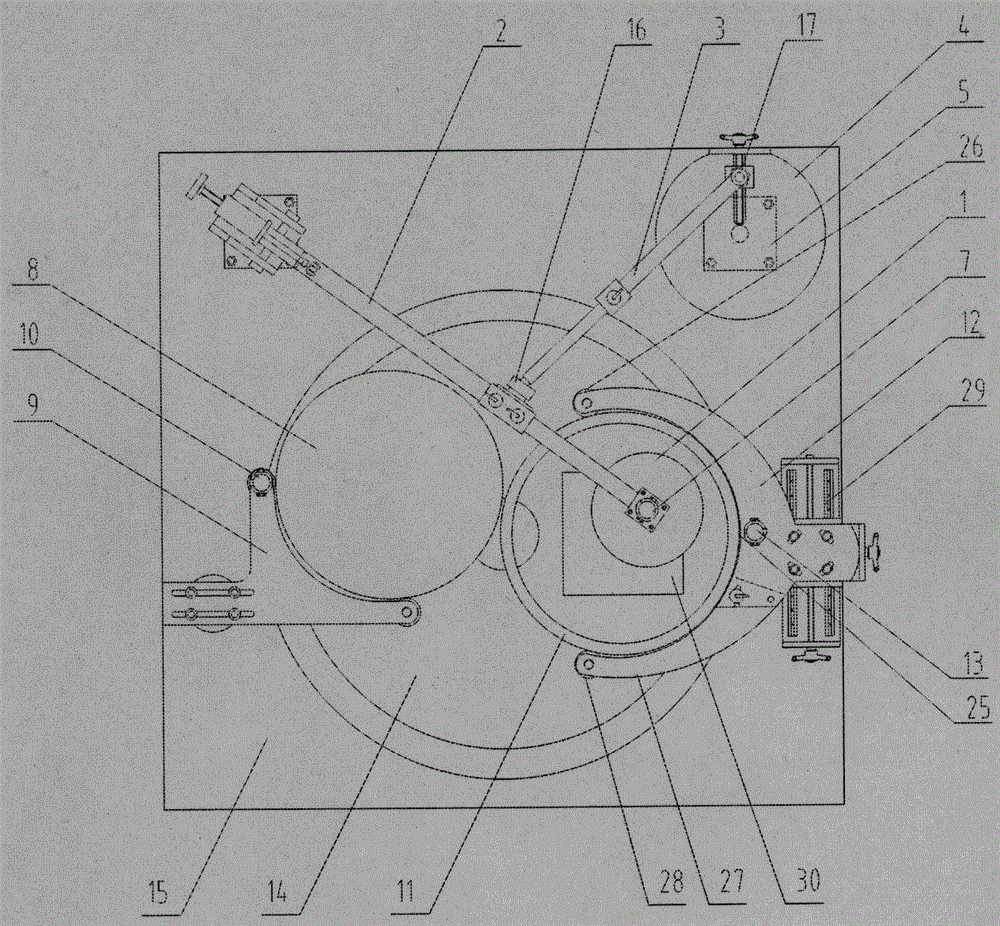

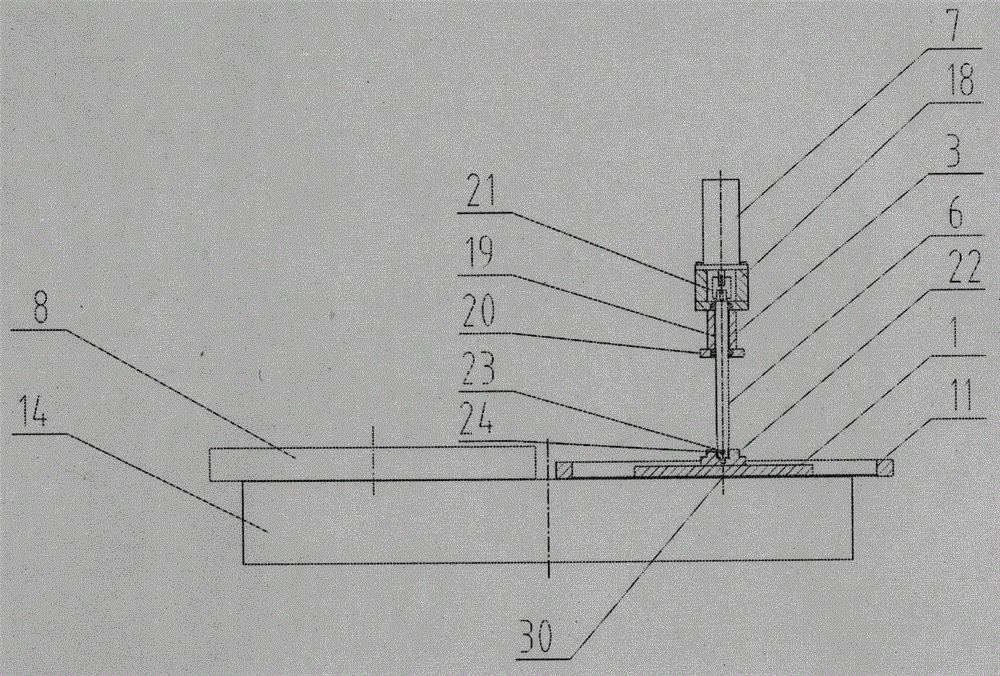

[0017] Such as Figure 1-2 , a double-sided polishing machine for large-diameter optical components, comprising: an upper polishing disc 1, a main swing rod 2, an auxiliary swing rod 3, an eccentric wheel 4, an eccentric wheel base 5, an upper polishing disc rotation shaft 6, and an upper polishing disc driving motor 7. Calibration disc 8, calibration disc caliper 9, calibration disc drive motor 10, workpiece ring 11, workpiece ring caliper 12, workpiece ring drive motor 13, lower polishing disc 14, main base 15; among them, main pendulum 2, auxiliary pendulum Rod 3, eccentric wheel 4, and eccentric wheel base 5 form the swing structure of the upper polishing disc to provide swinging motion for the upper polishing disc; one end of the main swing rod 2 is provided with the rotation axis 6 of the upper polishing disc, the driving motor 7 of the upper polishing disc, and the upper polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com