Fully-degradable compound non-woven for cleaning and manufacturing process thereof

A non-woven fabric and production process technology, which is applied in the field of fully degradable composite non-woven fabric for wiping and its production process, can solve the problems of severe chip shedding and low product strength, and achieve pollution-free, simple structure, and strong oil and water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A production process for fully degradable composite nonwovens for wiping, comprising the following steps:

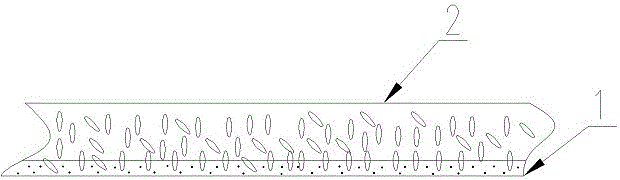

[0030] S1. Production of composite fiber layer 2: Use tencel with a length of 10mm and pulp fibers with a length of 2mm to form a cellulose fiber layer by using a wet-laid method in a ratio of 3:7, and then pump it under negative pressure Absorption and dehydration to obtain a gram weight of 40-45g / m 2 Composite fiber layer; when wet-laid, the concentration of the web-forming slurry is controlled at 1%-5%, and the web-forming speed is 200m / min; the output web curtain is dehydrated by 6 negative pressure suctions, and The efficiency of the negative pressure suction fan used for each negative pressure suction dehydration is controlled at 20%, 40%, 60%, 50%, 50%, 20% respectively.

[0031] S2. Production of spunbonded nonwoven fabric layer 1: Polylactic acid or chitosan is used as raw material, which is heated and melt-blown by a screw extruder, metered by a meterin...

Embodiment 2

[0037] A production process for fully degradable composite nonwovens for wiping, comprising the following steps:

[0038] S1. Production of composite fiber layer 2: Use tencel with a length of 10mm and pulp fibers with a length of 2mm to form a cellulose fiber layer by using a wet-laid method in a ratio of 4:6, and then pump it under negative pressure Absorption and dehydration to obtain a gram weight of 25-33g / m 2 Composite fiber layer; when wet-laid, the concentration of the web-forming slurry is controlled at 1%-5%, and the web-forming speed is 200m / min; the output web curtain is dehydrated by 6 negative pressure suctions, and The efficiency of the negative pressure suction fan used for each negative pressure suction dehydration is controlled at 20%, 30%, 50%, 50%, 40%, 20% respectively.

[0039] S2. Production of spun-bonded nonwoven fabric layer 1: Polylactic acid or chitosan is used as raw material, which is heated and melt-blown by a screw extruder, metered by a meteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com