Silver and black composite film and white film spaced mulch

A composite film, silver-black technology, used in synthetic resin layered products, plant protection, applications, etc., can solve the problem of low elongation at break of low-density polyethylene, unavoidable weeds and insect pests, and reducing the scope of application of crops, etc. problem, to achieve the effect of improving moisturizing, beneficial to crop growth, improving photosynthesis and insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

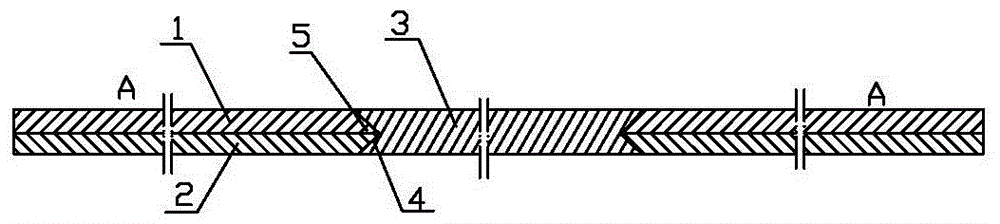

[0018] figure 1 A first embodiment of the present invention is given. refer to figure 1 The present invention is further described.

[0019] The silver-black composite film and the white film are arranged at intervals, and are composed of a silver layer film 1, a black layer film 2 and a white film 3, and it is characterized in that: the silver layer film 1 and the black layer film 2 are combined into a silver-black composite film Section A, silver-black composite film section A is divided into left and right sections, with a width of 600 mm, and the silver layer film 1 is on the upper layer, and the black layer film 2 is on the lower layer. The reflective effect is improved through the silver layer film 1. The silver reflective film is suitable for crops The opposite side increases photosynthesis, and the reflection is not suitable for the growth of insects. Insects like dark and dark places, which increases the yield of crops and reduces pests and diseases; the heat absorp...

Embodiment 2

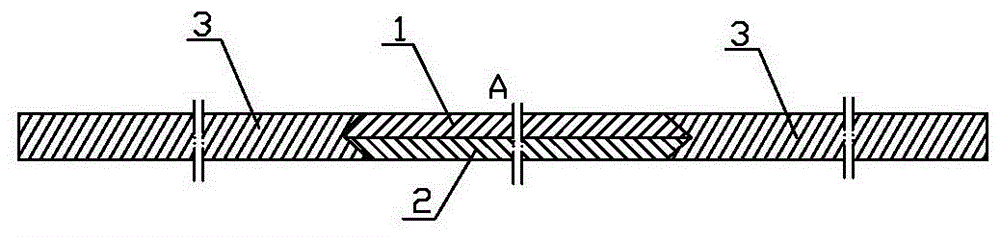

[0026] figure 2 A second embodiment of the present invention is given. refer to figure 2 The present invention is further described. The silver-black composite film and the white film are arranged at intervals, wherein the silver layer film 1, the black layer film 2 and the white film 3, and the silver layer film 1 and the black layer film 2 are composited into a silver-black composite film segment A, all the same as in Example 1 ; The white film 3 is divided into two sections, left and right, with a width of 800mm, and the silver-black composite film section A is separated in the middle, with a width of 800mm.

[0027] Its thickness and raw material proportioning are with embodiment 1.

Embodiment 3

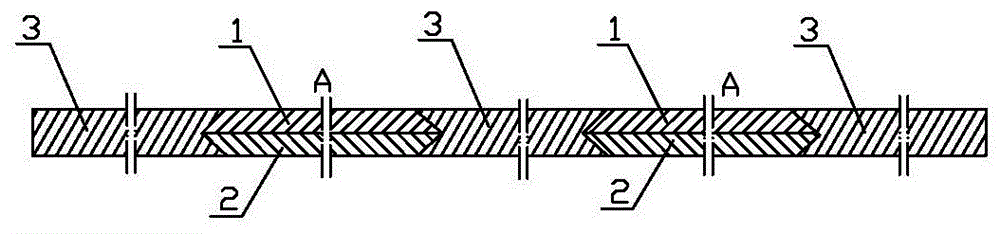

[0029] image 3 A third embodiment of the present invention is given. refer to image 3 The present invention is further described. The silver-black composite film and the white film are arranged at intervals, wherein the silver layer film 1, the black layer film 2 and the white film 3, and the silver layer film 1 and the black layer film 2 are composited into a silver-black composite film segment A, all the same as in Example 1 The white film 3 is divided into three sections, each of which has a width of 3000mm, and the adjacent white films 3 are separated by a silver-black composite film section A, with a width of 3000mm.

[0030] Its thickness and raw material proportioning are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com