Large-tonnage hydraulic mining vehicle braking system and method

A hydraulic braking, large-tonnage technology, applied in the direction of brakes, vehicle components, cooling brakes, etc., can solve the problems of separate control of the braking process, increase the damage of the braking system, waste energy, etc., to achieve intelligent cooling, guarantee Safety, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

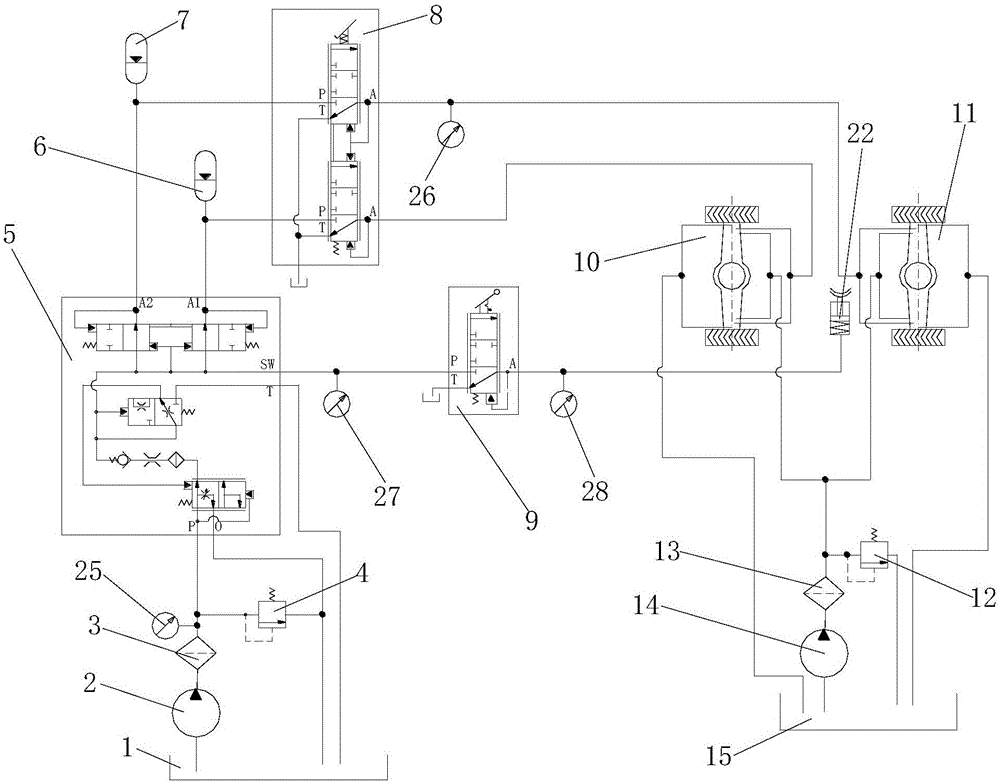

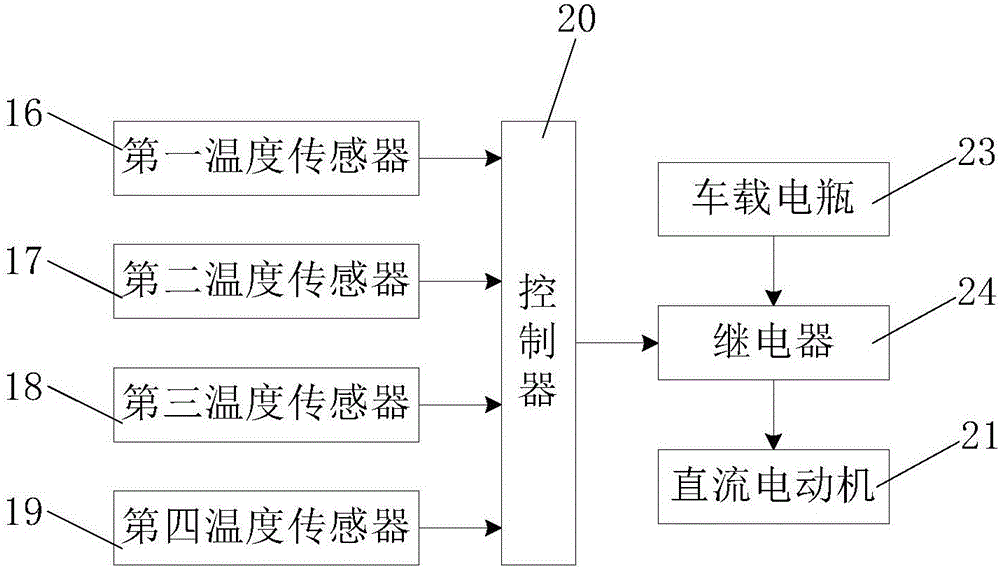

[0038] Such as figure 1 As shown, the large-tonnage mining vehicle hydraulic braking system of the present invention includes a hydraulic braking unit, a hydraulic cooling unit and a cooling control system. valve 8 and parking brake handle valve 9, a first hydraulic pump 2, a first filter 3 and a first overflow valve 4 are arranged between the hydraulic oil tank 1 and the two-way filling valve 5, and the first A hydraulic pump 2 is powered by the vehicle engine, the oil inlet of the first hydraulic pump 2 is connected to the hydraulic oil tank 1 through a pipeline, and the oil outlet of the first hydraulic pump 2 is connected to the inlet of the first filter 3 through a pipeline. The P port of the two-way filling valve 5 is connected to the oil outlet of the first filter 3 and the oil inlet of the first relief valve 4 through a three-way interface and a pipeline, and the two-way filling valve Both the T port and the O port of the liquid valve 5 are connected back to the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com