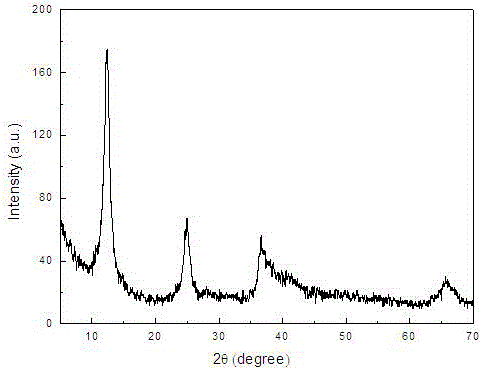

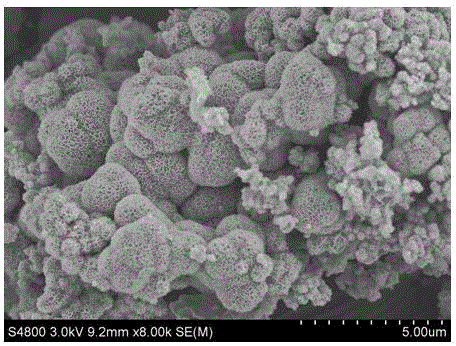

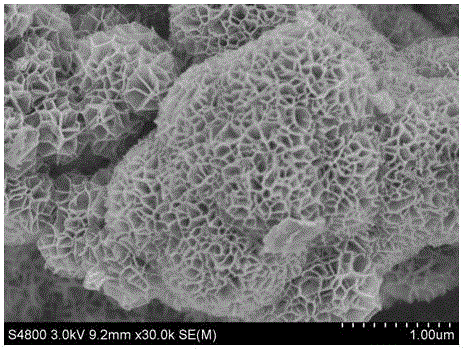

Coralline porous delta-MnO2 and preparation method thereof

A coral-like, mixed solution technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of long process flow, powder agglomeration, large product loss, etc., and achieve the effect of simple process, complete development and process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Coral-like porous δ-MnO 2 The preparation method comprises the following steps:

[0025] Step 1. Put 8×10 -4 mol KMnO 4 Add 20 mL of deionized water and stir to obtain a homogeneous solution;

[0026] Step 2. Put 2×10 -4 mol MnSO 4 Add 20 mL of deionized water and stir to obtain a homogeneous solution, which is mixed with the KMnO obtained in step 1 4 The solution is mixed evenly, in which KMnO 4 with MnSO 4 The molar ratio is 4:1;

[0027] Step 3, using 0.1M dilute hydrochloric acid to adjust the pH value of the mixed solution obtained in step 2 to 3.0;

[0028] Step 4, transfer the mixed solution whose pH value is 3.0 in step 3 to the autoclave, and the mixed solution volume is controlled at 70% of the reactor volume;

[0029] Step 5: After reacting at 140°C for 36 hours, cool down the temperature, wash the obtained product with distilled water to neutrality, then wash once with absolute ethanol, and finally dry it in an oven at 80°C to obtain coral-like poro...

Embodiment 2

[0031] Coral-like porous δ-MnO 2 The preparation method comprises the following steps:

[0032] Step 1. Put 1.2×10 -3 mol KMnO 4 Add 20 mL of deionized water and stir to obtain a homogeneous solution;

[0033] Step 2. Put 2×10 -4 mol MnSO 4 Add 20 mL of deionized water and stir to obtain a homogeneous solution, which is mixed with the KMnO obtained in step 1 4 The solution is mixed evenly, in which KMnO 4 with MnSO 4 The molar ratio is 6:1;

[0034] Step 3, using 0.1M dilute hydrochloric acid to adjust the pH value of the mixed solution obtained in step 2 to 4.0;

[0035] Step 4, transfer the mixed solution whose pH value is 4.0 in step 3 to the autoclave, and the volume of the mixed solution is controlled at 65% of the reactor volume;

[0036] Step 5. After reacting at 160°C for 24 hours, cool down the temperature, wash the obtained product with distilled water to neutrality, then wash once with absolute ethanol, and finally dry it in an oven at 80°C to obtain coral-...

Embodiment 3

[0038] Coral-like porous δ-MnO 2 The preparation method comprises the following steps:

[0039] Step 1. Put 1.6×10 -3 mol KMnO 4 Add 20 mL of deionized water and stir to obtain a homogeneous solution;

[0040] Step 2. Put 2×10 -4 mol MnSO 4 Add 20 mL of deionized water and stir to obtain a homogeneous solution, which is mixed with the KMnO obtained in step 1 4 The solution is mixed evenly, in which KMnO 4 with MnSO 4 The molar ratio is 8:1;

[0041] Step 3, using 0.1M dilute hydrochloric acid to adjust the pH value of the mixed solution obtained in step 2 to 5.0;

[0042] Step 4, transfer the mixed solution whose pH value is 5.0 in the step 3 to the autoclave, and the volume of the mixed solution is controlled at 60% of the reactor volume;

[0043] Step 5. After the reaction kettle was reacted at 180°C for 12 hours, the temperature was cooled, and the obtained product was washed with distilled water to neutrality and then washed once with absolute ethanol, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com