Method of starting microbial fuel cell by adding inoculum to treat cow dung fermentation biogas slurry

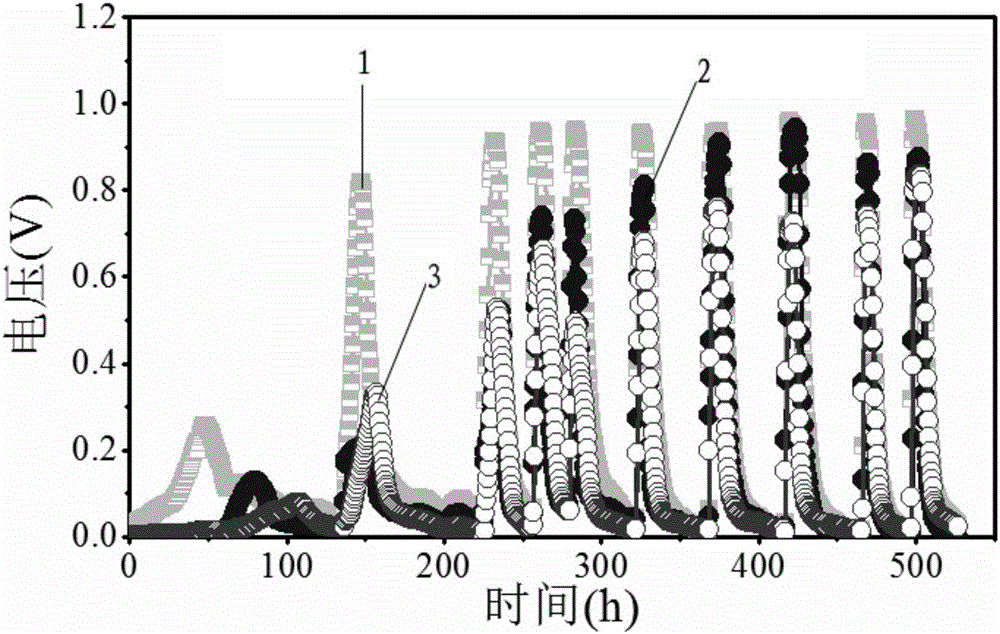

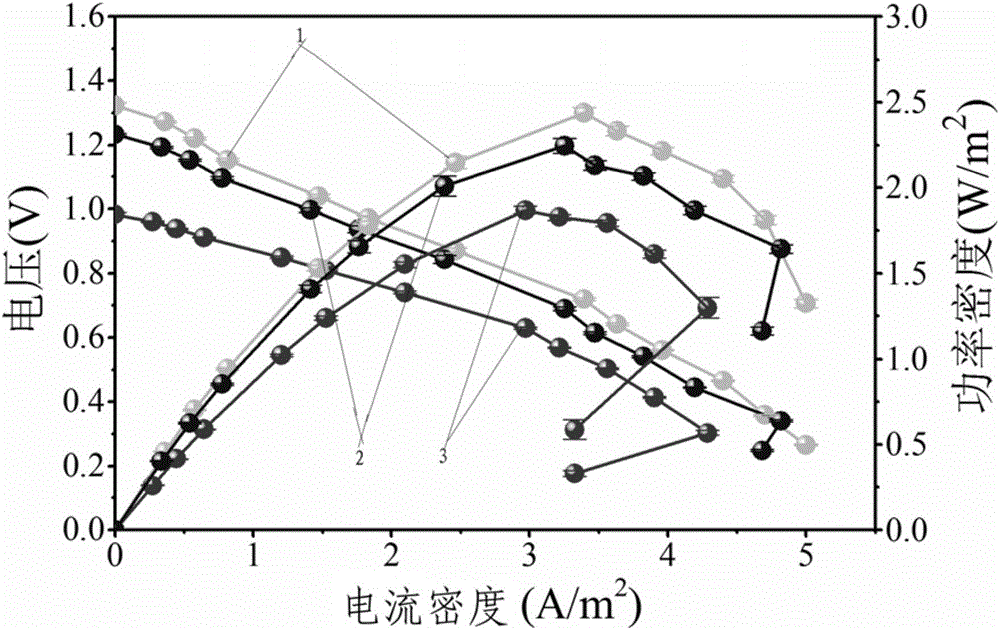

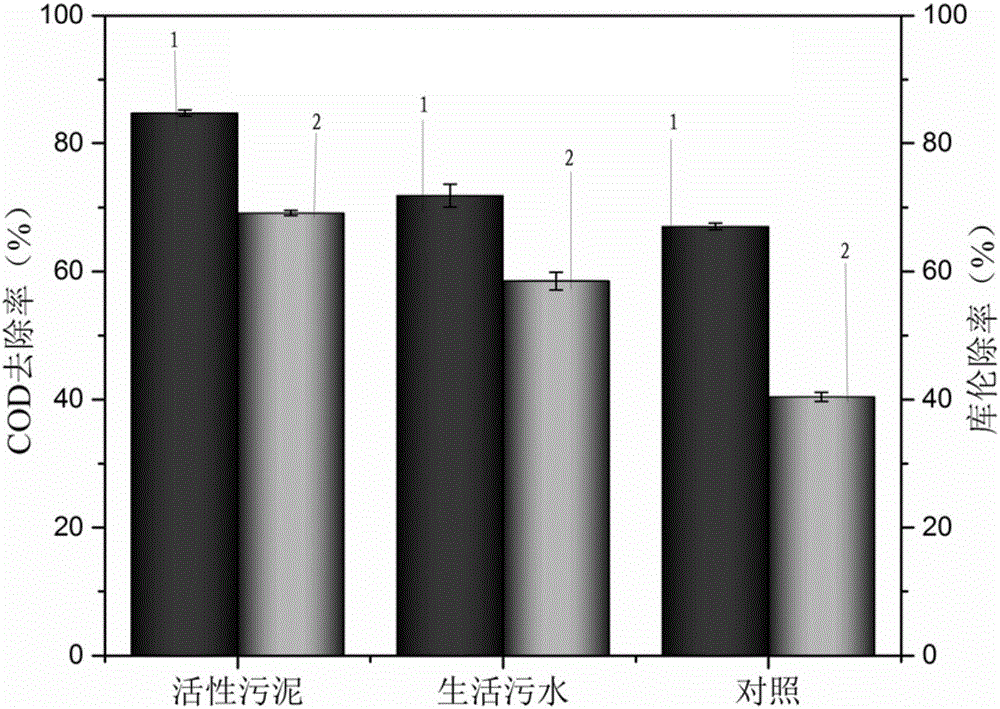

A fuel cell and microbial technology, applied in the environmental field, can solve the problems of microbial fuel cells such as long time, unsatisfactory treatment effect, unstable output voltage, etc., achieve short start-up reactor time, short start-up time, and increase output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the method for processing cow dung fermentation biogas slurry by adding inoculum to start the microbial fuel cell of the present embodiment is carried out according to the following steps:

[0024] 1. Prepare the culture medium for feeding into the microbial fuel cell reactor: add 0.1-10g / L sodium acetate, 0.1-10ml / L vitamin solution, 0.1-15ml / L mineral element solution and COD to 200-5000mg / L respectively The fermented biogas slurry of cow dung is added into the container according to the ratio of (30-50): (0.8-1.2): (2-3): (150-170) in parts by weight to obtain the prepared medium;

[0025] 2. Add the prepared medium into the microbial fuel cell reactor, and connect the reference electrode on the anode of the microbial fuel cell; at the initial stage of starting the microbial fuel cell, inoculate the inoculum at an inoculation amount of 1%-20%. In the reactor of microbial fuel cell;

[0026] 3. Use a wire to connect a 500-1000Ω resistor betwe...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that described in step one, respectively 2-8g / L sodium acetate, 2-8ml / L vitamin solution, 2-10ml / L mineral element solution and COD are 500-1500mg / L cow dung fermentation biogas slurry is added into the container at the ratio of 40:1:2.5:156.4 by weight to obtain the prepared medium. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the anode of the microbial fuel cell is a carbon brush made of carbon fibers; / cm 2 Pt catalyst. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com