Preparation method of color roof tile

A roof tile and color technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems affecting human life, polluting the environment, wasting tailings resources, etc., to reduce production costs and simple operation , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

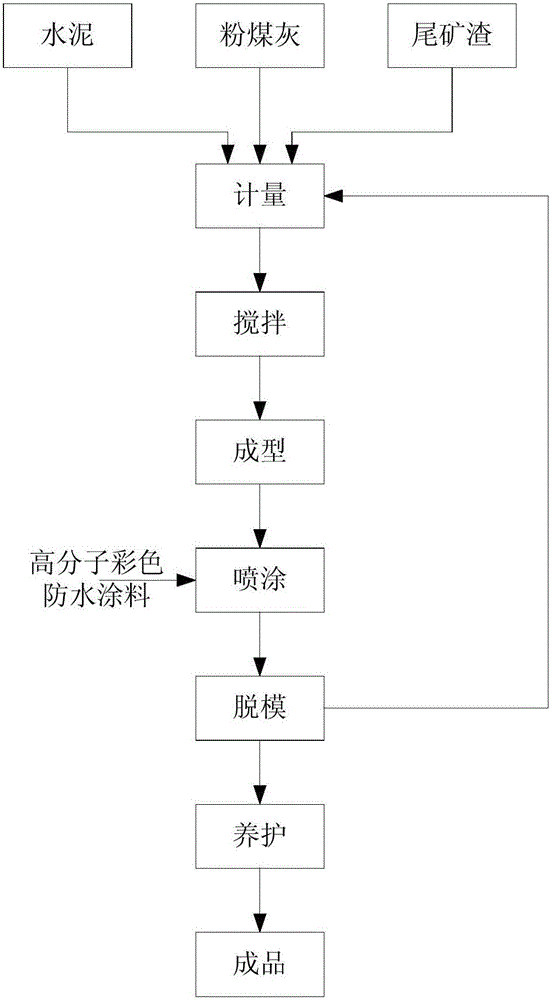

[0018] A method for preparing colored roof tiles, comprising the following steps:

[0019] 1) Raw material measurement: select cement, fly ash, and tailings slag, wherein the ratio of raw materials is 45 parts of cement, 20 parts of fly ash, and 35 parts of tailings slag;

[0020] 2) Stirring: Put the measured cement, fly ash and tailings slag into the concrete mixer for mixing;

[0021] 3) Molding: The mixed raw materials that have been stirred are dropped onto the bottom mold of the forming mold through a quantitative feeder, and are formed by a compression molding machine at one time, and pressed into a tile blank of a certain shape;

[0022] 4) Spraying: Use a spraying machine to spray waterproof paint on the surface of the formed tile blank. The waterproof paint is a polymer cement tile color waterproof paint. The polymer cement tile color waterproof paint includes metal oxides, chemical enhancers and acrylate waterproofing agents;

[0023] 5) Post-processing: the spraye...

Embodiment 2

[0025] A method for preparing colored roof tiles, comprising the following steps:

[0026] 1) Raw material measurement: select cement, fly ash, and tailings slag, wherein the ratio of raw materials is 40 parts of cement, 30 parts of fly ash, and 30 parts of tailings slag;

[0027] 2) Stirring: Put the measured cement, fly ash and tailings slag into the concrete mixer for mixing;

[0028] 3) Molding: The mixed raw materials that have been stirred are dropped onto the bottom mold of the forming mold through a quantitative feeder, and are formed by a compression molding machine at one time, and pressed into a tile blank of a certain shape;

[0029] 4) Spraying: Use a spraying machine to spray waterproof paint on the surface of the formed tile blank. The waterproof paint is a polymer cement tile color waterproof paint. The polymer cement tile color waterproof paint includes metal oxides, chemical enhancers and acrylate waterproofing agents;

[0030] 5) Post-processing: the spraye...

Embodiment 3

[0032] A method for preparing colored roof tiles, comprising the following steps:

[0033] 1) Raw material measurement: select cement, fly ash, and tailings slag, wherein the ratio of raw materials is 50 parts of cement, 10 parts of fly ash, and 40 parts of tailings slag;

[0034] 2) Stirring: Put the measured cement, fly ash and tailings slag into the concrete mixer for mixing;

[0035] 3) Molding: The mixed raw materials that have been stirred are dropped onto the bottom mold of the forming mold through a quantitative feeder, and are formed by a compression molding machine at one time, and pressed into a tile blank of a certain shape;

[0036] 4) Spraying: Use a spraying machine to spray waterproof paint on the surface of the formed tile blank. The waterproof paint is a polymer cement tile color waterproof paint. The polymer cement tile color waterproof paint includes metal oxides, chemical enhancers and acrylate waterproofing agents;

[0037] 5) Post-processing: the spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com