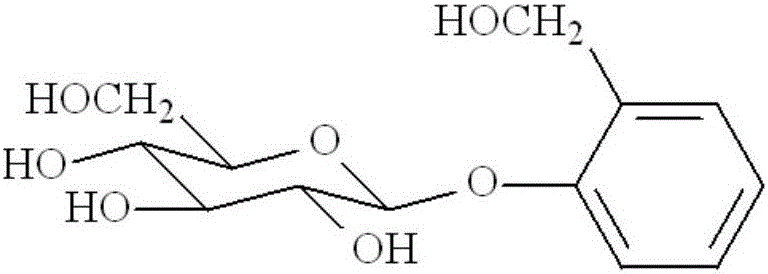

Process for processing byproducts of salicin production using Salix babylonica L. bark

A by-product, salicin technology, which is applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc., can solve the problem of waste of resources, achieve the effect of saving resources, requiring less equipment, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolution: Add 20 times the amount of hot water to dissolve the by-products, stir evenly, and let stand for 24 hours.

[0027] Filtration: Plate-and-frame filtration to remove insoluble matter and collect the clarified filtrate.

[0028] Column packing: 30 times the volume of macroporous resin, wash the impurities with ethanol, and wash with water until there is no alcohol.

[0029] Column loading: the filtrate is loaded onto the column, and is adsorbed to saturation by a macroporous resin. The macroporous resin used is LSD-21 macroporous resin, washed with water, and then eluted with ethanol with a concentration of 70-85% for analysis, and collected and eluted liquid, and concentrated under reduced pressure.

[0030] Decolorization: add a decolorizer to the concentrated solution, heat to about 70°C, stir for 30 minutes, filter with plate and frame, and collect the filtrate.

[0031] Crystallization: The filtrate was concentrated under reduced pressure at 0.08Mpa an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com