PU (polyurethane) coated skin and preparation method thereof

A production method and polyurethane technology, applied in the field of chemical products, can solve the problems of increasing the production cost of PU skin, high price, and restricting industrial application, etc., and achieve good physical properties and economic performance, clear texture, and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

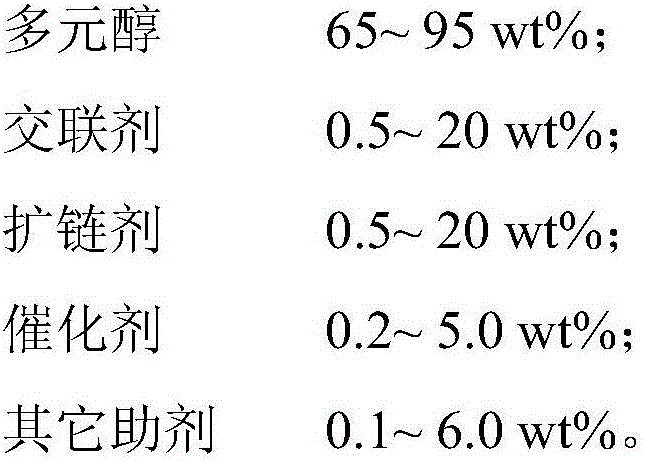

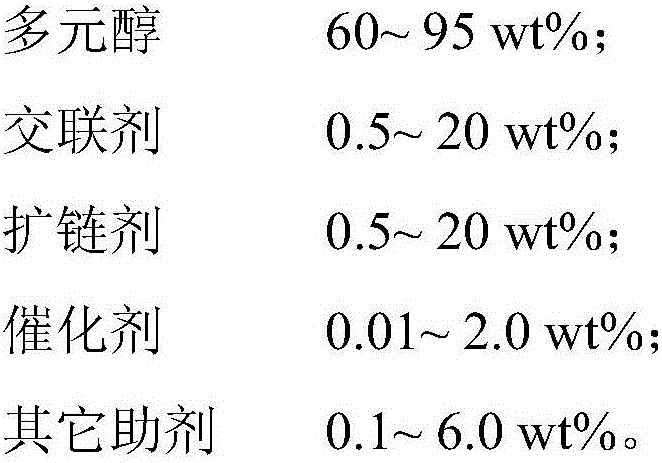

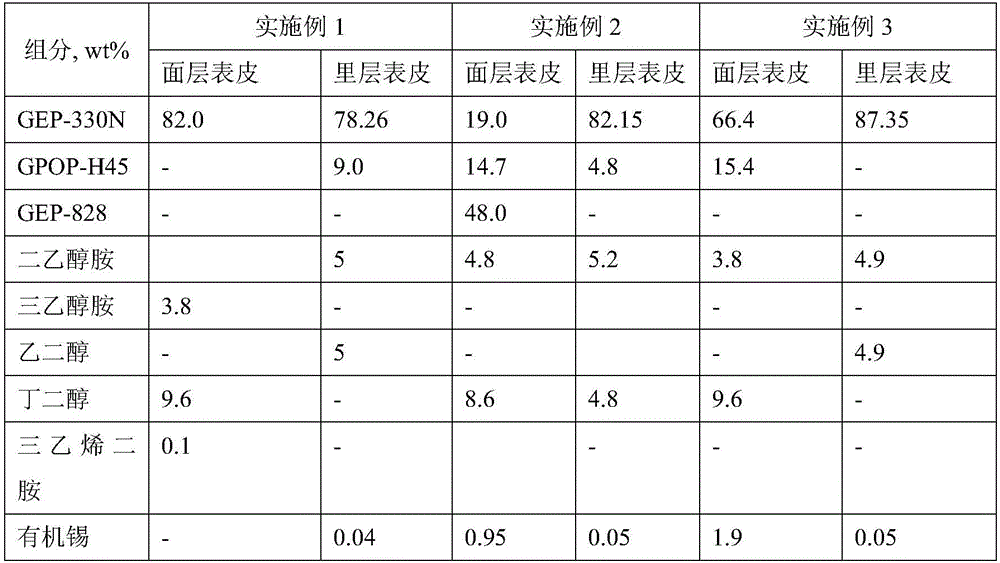

[0034] The formula of product is as shown in table 1:

[0035] Table 1

[0036]

[0037]

[0038] The raw materials stated in the table are:

[0039] GEP-330N: Highly active polyether polyol, hydroxyl value 35mg KOH / g, functionality 3, Sinopec Shanghai Gaoqiao Branch;

[0040] GPOP-H45: Highly active polymer polyether polyol, hydroxyl value 21mg KOH / g, functionality 3, Sinopec Shanghai Gaoqiao Branch;

[0041] GEP-828: Highly active polyether polyol, hydroxyl value 28mg KOH / g, functionality 3, Sinopec Shanghai Gaoqiao Branch;

[0042] Diethanolamine: commercially available;

[0043] Triethanolamine: commercially available;

[0044] Ethylene glycol: commercially available;

[0045] Butanediol: commercially available;

[0046] Triethylenediamine: American Air Products Company;

[0047] Organotin catalyst: American Momentive Company;

[0048] Organobismuth / zinc catalyst: Shepherd Chemical Company;

[0049] Other additives: surfactants, antioxidants, light stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com