Method for making stainless steel texture component in building landscape model by 3D printing

A 3D printing and landscape model technology, applied in the field of 3D printing, can solve the problems of low proportion and size accuracy, low degree of simulation, poor overall effect, etc., and achieve the effect of low cost, low temperature and strong texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

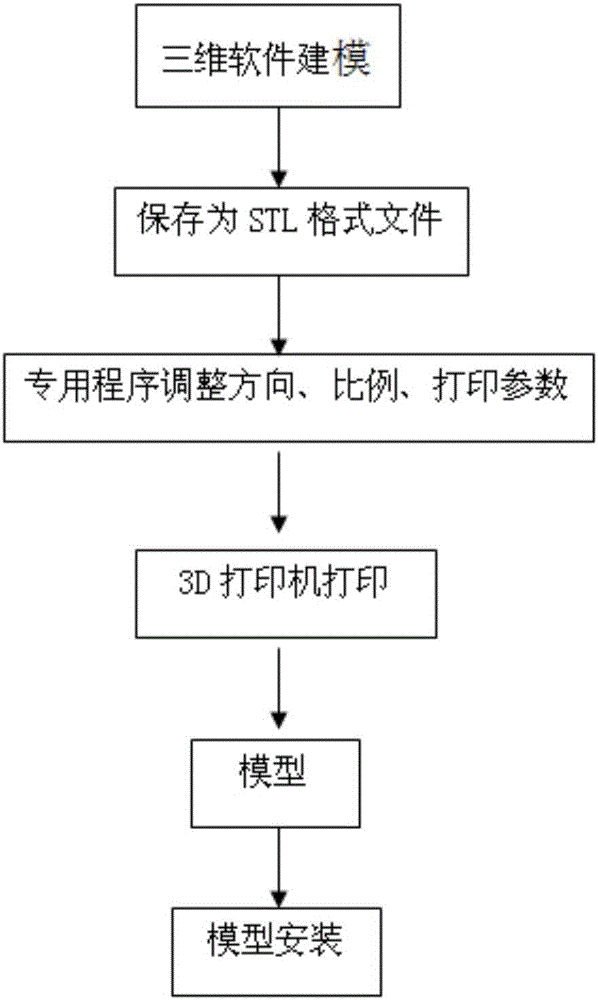

[0018] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0019] In this embodiment, to make stainless-steel railings, first use various three-dimensional software to design three-dimensional models of various buildings, components, and decorations in the architectural environment design model, save them in stl format, import them into a 3D printer, and use polylactic acid-ferrochrome powder The composite 3D printing wire is used as the raw material, and the fused deposition 3D printing machine quickly prints out the stainless steel-like texture components.

[0020] Specifically, first, the 3D printing wire needs to be prepared:

[0021] Select ferrochrome powder with a particle size of 200-800 mesh and a moisture content below 1%, and use a coupling agent for surface treatment. The coupling agent is titanate coupling agent or aluminate coupling agent, and the dosage is the mass of ferrochrome powder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com