Novel annealing furnace

An annealing furnace, a new type of technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as uneven heating, long heating time, deformation of wire pipes, etc., achieve rapid heating and heat preservation, rapid and uniform temperature rise, and improve product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

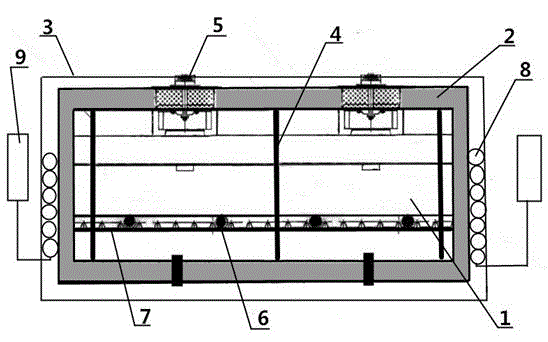

[0013] Embodiment one: a kind of novel annealing furnace

[0014] Such as figure 1 As shown, the present invention provides a novel annealing furnace, comprising a body of furnace 1, an insulation layer 2, a shell 3, and an electromagnetic heating system; The top of each heating chamber is provided with a hot air circulation fan 5, and the bottom of each heating chamber is provided with a furnace roller 6 and an electromagnetic heating plate 7, and the furnace roller 6 is arranged on the electromagnetic heating plate 7; There is an air duct underneath; the air duct is provided with a blowing port, and the blowing port is provided with a dust cover; the electromagnetic heating system includes multiple sets of magnetic loop wires 8 arranged on both sides of the shell and Electrically connected controller 9 . The heat insulation board 4 includes one layer of ceramic fiber board and two layers of stainless steel board. The furnace roller 6 is a ceramic furnace roller. A monito...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap