Assembly type tank steel plate-concrete combined member and construction method thereof

A combined component and prefabricated technology, used in large-capacity bulk material storage, building types, buildings, etc., can solve the problems of adverse effects on overall mechanical performance, difficult construction, and high cost, and achieve integrity and airtight safety. The effect of improving the shear bearing capacity and the high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

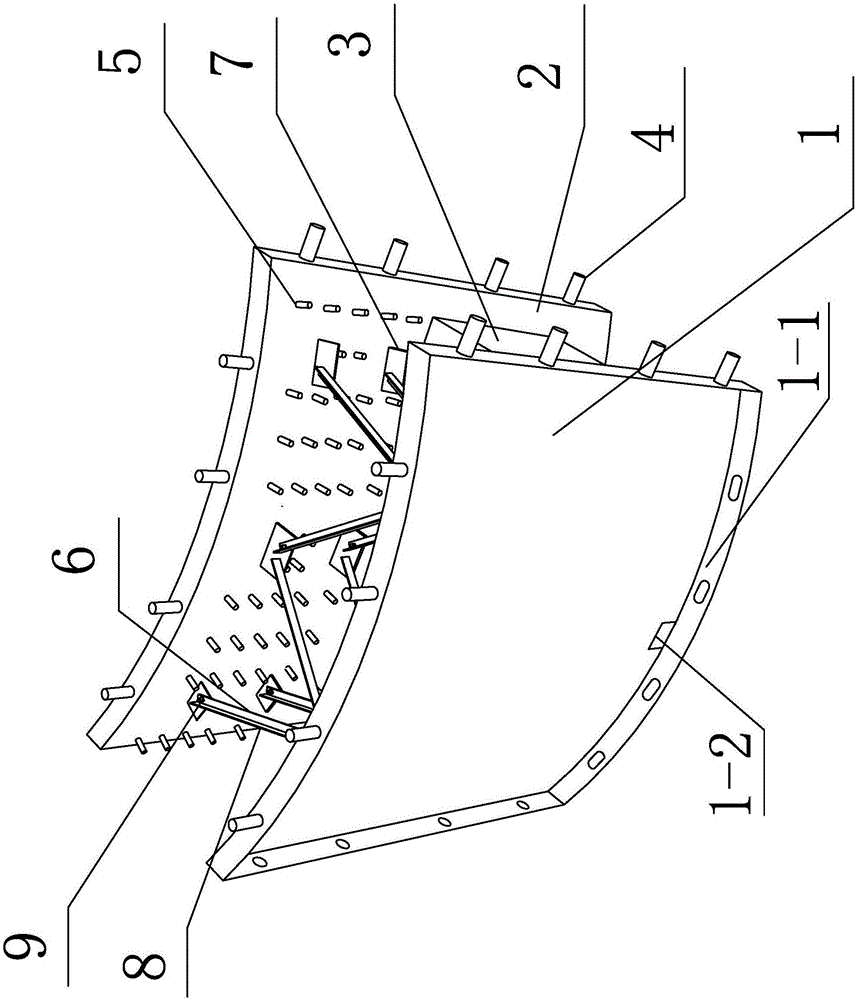

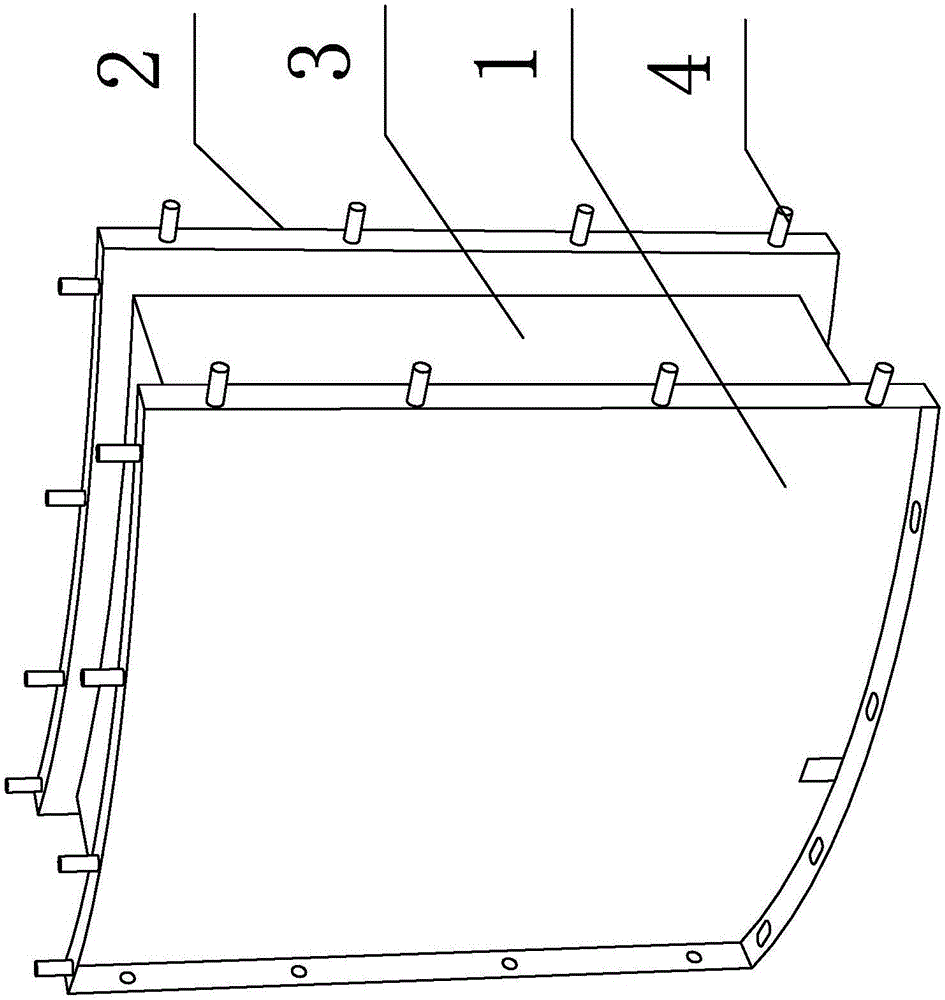

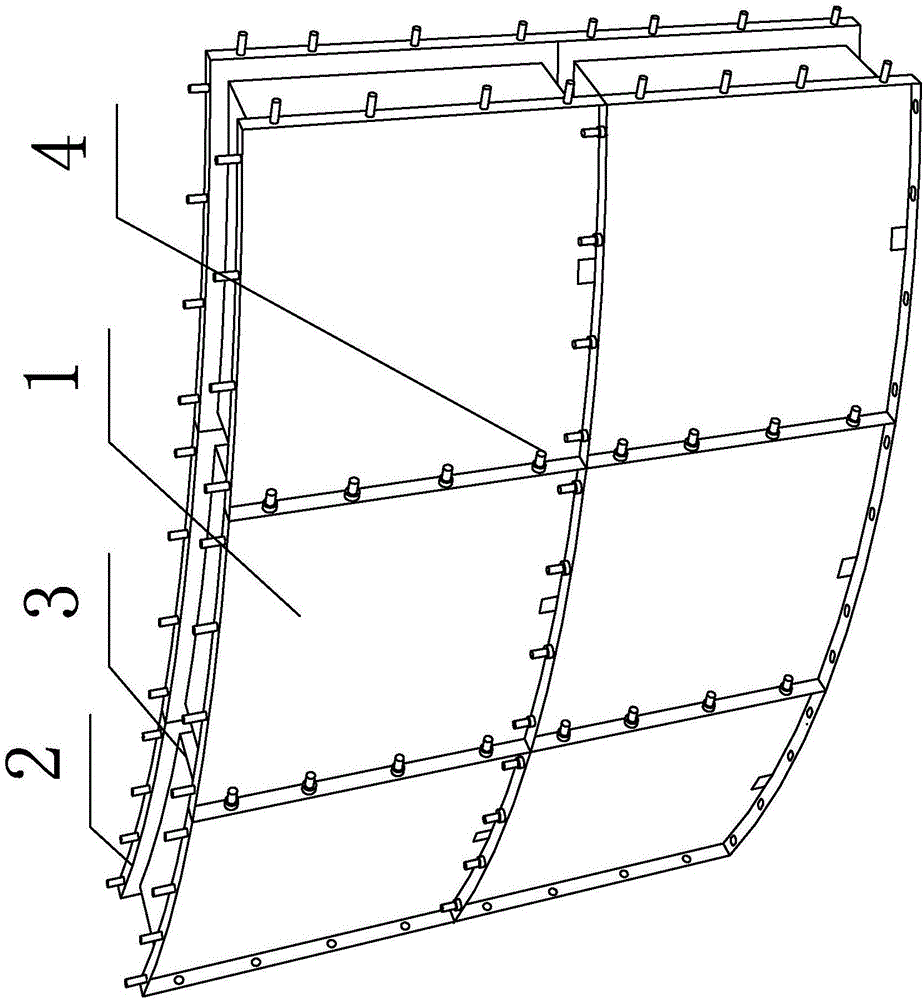

[0021] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment mode, an assembled tank steel plate-concrete composite member described in this embodiment mode, which includes an outer layer steel plate 1, an inner layer steel plate 2, a concrete block 3, a tie bar assembly 6, a plurality of fixing bolts 4 and a plurality of A stud 5, the outer steel plate 1 is an arc-shaped bent plate, the inner surface of the outer layer steel plate 1 is evenly distributed and fixed with a plurality of studs 5, the inner steel plate 2 is an arc-shaped bent plate, and the outer surface of the inner steel plate 2 A plurality of pegs 5 are evenly distributed and fixedly installed, and the edge of the outer surface of the outer layer steel plate 1 is fixedly installed with an outer layer steel plate edge slat 1-1, which is located on the upper end surface of the outer layer steel plate edge slat 1-1 above the outer layer steel plate 1 A plurality of fixing bolts 4 ar...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, a kind of fabricated tank steel plate-concrete composite member described in this embodiment. The two ends of the tie rod 8 are respectively provided with angle steel tie bolts 9, and the outer surface of the inner steel plate 2 is arranged side by side with a plurality of lugs 7 from top right to bottom, and the lugs 7 are fixedly installed on the inner steel plate 2, and the outer steel plate The inner surface of 1 is provided with multiple lugs 7 side by side in sequence, and the lugs 7 are fixedly installed on the outer steel plate 1, and the multiple lugs 7 on the inner steel plate 2 and the multiple lugs 7 on the outer steel plate 1 are arranged alternately , and an ear plate 7 on the inner steel plate 2 is connected with two adjacent ear plates 7 on the outer layer steel plate 1 with an angle steel tie rod 8, and one end of the angle steel tie rod 8 is connected with the ea...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 1-Figure 3Describe this embodiment, the prefabricated tank steel plate-concrete composite member described in this embodiment, the outer steel plate 1 is processed with a reserved hole 1 for the outer steel plate near the edge 1-1 of the outer steel plate at the bottom end -2. During on-site installation, the concrete can fill the horizontal cavity and vertical cavity between adjacent steel plate-concrete composite component modules. After the concrete is filled, the outer layer is reserved on each outer steel plate 1 by laser arc welding The reserved holes 1-2 of the steel plate are welded and plugged with steel plates, and other compositions and connections are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com