Negative pressure heat pump drying device and working method thereof

A heat pump drying and negative pressure technology, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of energy loss, large energy consumption, etc., and achieve convenient operation, low energy consumption and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

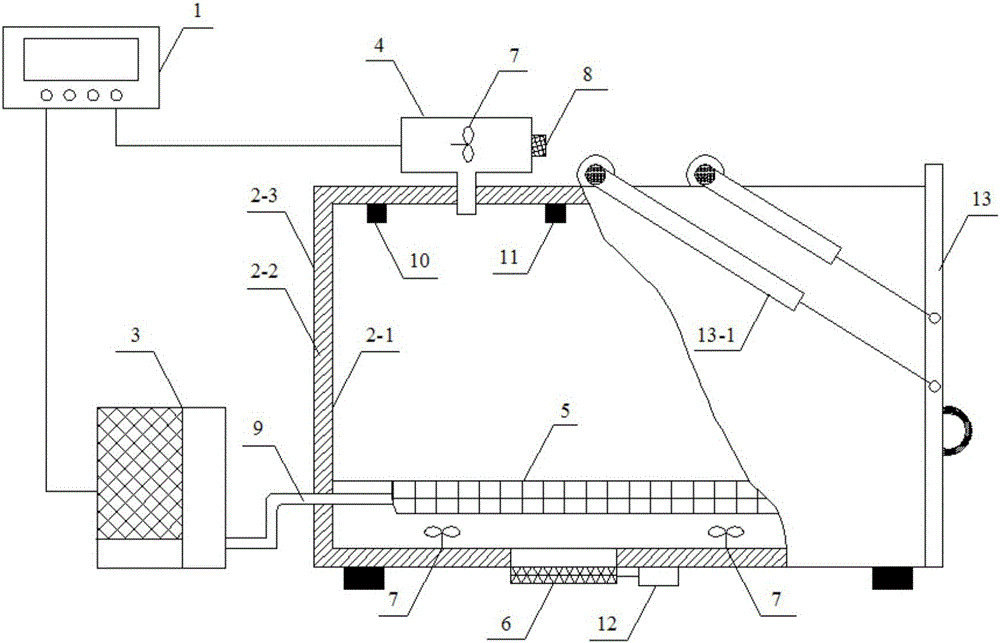

[0024] Such as figure 1 As shown, this embodiment discloses a negative pressure heat pump drying device and its working method, including a microcomputer controller 1, a drying room 2, a heat pump host 3, an air extractor 4, a condenser 5, an air inlet door 6, and an air inlet door Motor 12, three circulation fans 7, pressure sensor 10 and temperature sensor 11.

[0025] Drying room 2 is made up of three-sided drying room body and dodge door 13, and drying room body is made up of a box-type box body by inner layer 2-1, insulation layer 2-2 and outer layer 2-3, and dodge door 13 is included on it The provided spring pull rod 13-1. The heat pump host 3 is arranged outside the drying room 2, and the heat pump host 3 is connected to the condenser 5 arranged inside the drying room 2 through the refrigerant circulation pipe 9, and the condenser 5 is arranged at the lower half of the inside of the drying room 2; the air inlet door 6 is set At the bottom of the drying room 2, two ci...

Embodiment 2

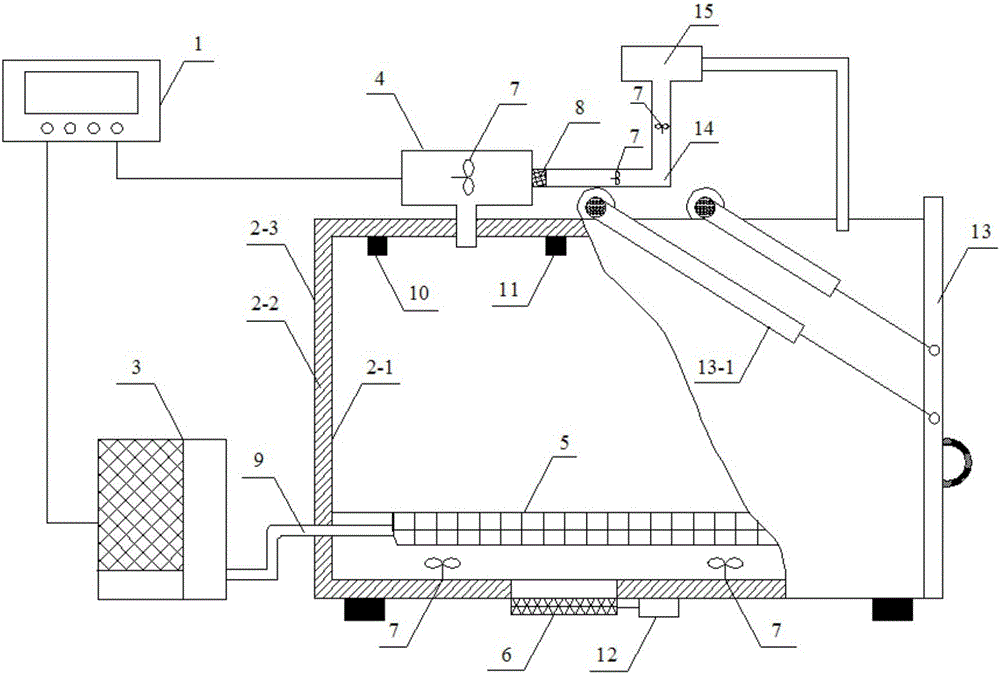

[0033] Such as figure 2 As shown, different from Embodiment 1, this embodiment also includes an exhaust pipe 14 and an evaporator 15, one end of the exhaust pipe 14 is connected to the exhaust port 8, and two circulating fans are arranged in the exhaust pipe 14 7. The circulation fan 7 is electrically connected to the microcomputer controller 1, the evaporator 15 is connected to the other end of the exhaust pipe 14, and the evaporator 15 is connected to the drying room 2. The exhaust pipe 14 is connected to the exhaust port 8, and the exhaust pipe 14, under the action of the circulating fan 7, introduces the high-temperature water vapor discharged from the drying room 2 into the evaporator 15, and the evaporator 15 releases heat from the high-temperature water vapor Liquefied into liquid and discharged, and at the same time, the heat released by liquefaction is introduced into the drying room 2 for heating, so as to maximize energy utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com