Preparation method and application of self-supporting Pd-Ag-Ni ternary metal catalyst

A ternary metal and catalyst technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve problems such as expensive equipment and non-compliance, and achieve the effect of simple operation, few steps, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of self-supporting Pd-Ag-Ni ternary metal catalyst (A)

[0036] The commercialized nickel foam was washed with acetone, 1mol / L HCl solution and ultrapure water in turn, and then used; the purified nickel foam was immersed in a solution containing 20mmol / L AgNO 3 In the solution of the precursor, take it out after standing for 10min, rinse it with enough ultrapure water for 3 times, dry it, and set aside; soak the Ag-substituted nickel foam in the solution containing 25mmol / L K 2 PdCl 4 In the solution of the precursor, take it out after standing for 5 minutes, rinse with sufficient ultrapure water for 3 times, dry at room temperature for 30 minutes, and set aside.

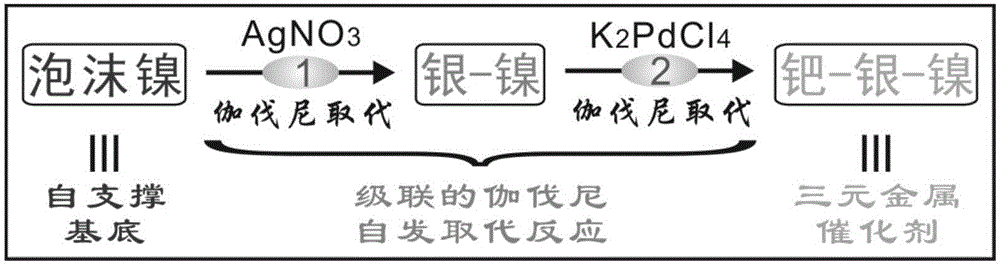

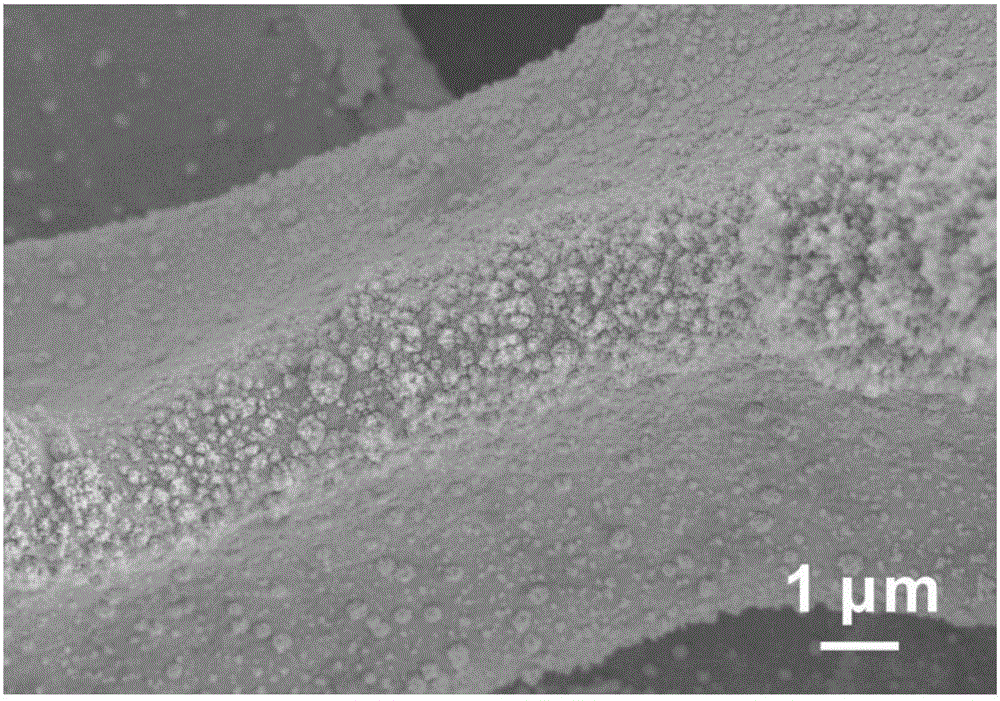

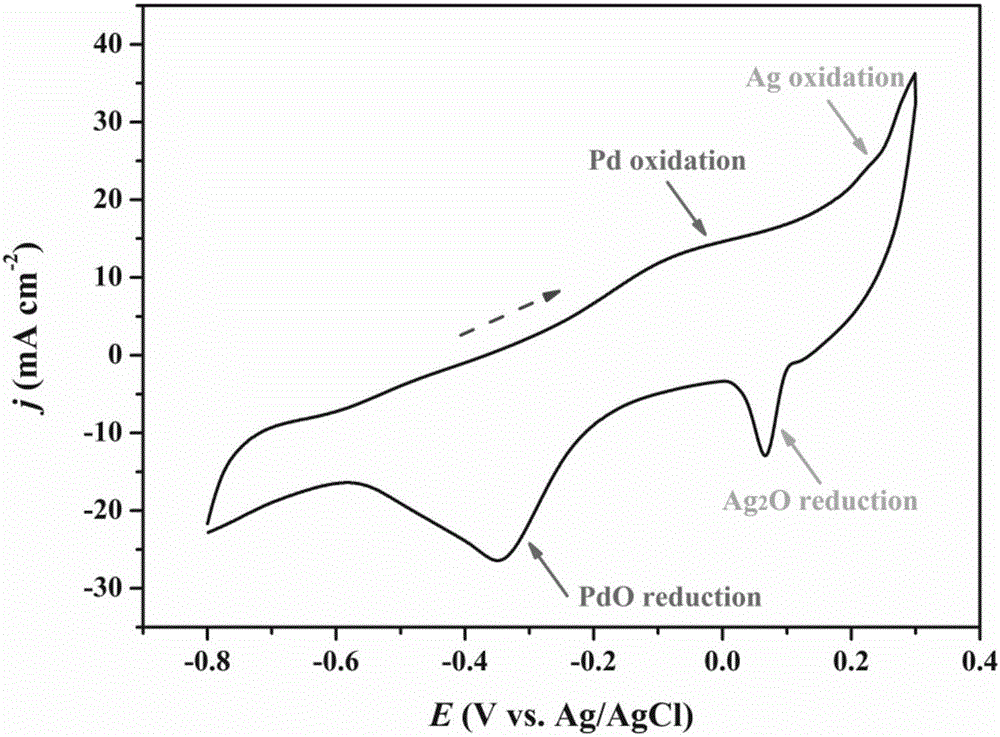

[0037] figure 1 It is a flow chart for the preparation of the Pd-Ag-Ni ternary metal catalyst proposed by the present invention. Using commercial porous nickel foam as a self-supporting substrate, the Ni and Ag + Replacement occurs, and then let the generated Ag and [PdCl 4 ] 2- A partia...

Embodiment 2

[0044] 1. Preparation of self-supporting Pd-Ag-Ni ternary metal catalyst (B)

[0045] The commercialized nickel foam was washed with acetone, 1mol / L HCl solution and ultrapure water in turn, and then used; the purified nickel foam was immersed in a solution containing 20mmol / L AgNO 3 In the solution of the precursor, take it out after standing for 10min, rinse it with enough ultrapure water for 3 times, dry it, and set aside; soak the Ag-substituted nickel foam in the solution containing 25mmol / L K 2 PdCl 4 In the solution of the precursor, take it out after standing for 2 minutes, rinse with sufficient ultrapure water for 3 times, dry at room temperature for 30 minutes, and set aside. As determined by ICP-OES, the atomic ratio of Pd to Ag on the Ni surface is 24:76, denoted as Pd 0.24 -Ag 0.76 -Ni.

[0046] 2. Electrocatalytic oxidation of methanol in alkaline environment

[0047] Self-supporting Pd prepared by 0.24 -Ag 0.76 -Ni ternary metal catalyst directly as the w...

Embodiment 3

[0049] 1. Preparation of self-supporting Pd-Ag-Ni ternary metal catalyst (C)

[0050] The commercialized nickel foam was washed with acetone, 1mol / L HCl solution and ultrapure water in turn, and then used; the purified nickel foam was immersed in a solution containing 20mmol / L AgNO 3 In the solution of the precursor, take it out after standing for 10min, rinse it with enough ultrapure water for 3 times, dry it, and set aside; soak the Ag-substituted nickel foam in the solution containing 25mmol / L K 2 PdCl 4 In the solution of the precursor, take it out after standing for 10 minutes, rinse it with enough ultrapure water for 3 times, dry it at room temperature for 30 minutes, and set it aside. As determined by ICP-OES, the atomic ratio of Pd to Ag on the Ni surface is 72:28, denoted as Pd 0.72 -Ag 0.28 -Ni.

[0051] 2. Electrocatalytic oxidation of methanol in alkaline environment

[0052] Self-supporting Pd prepared by 0.72 -Ag 0.28 -Ni ternary metal catalyst directly as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com