Heat pipe type winding enhanced heat motor

A heat pipe type and winding technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of difficult and fast heat transfer, and achieve the effect of improving heat conduction efficiency, improving heat dissipation capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below.

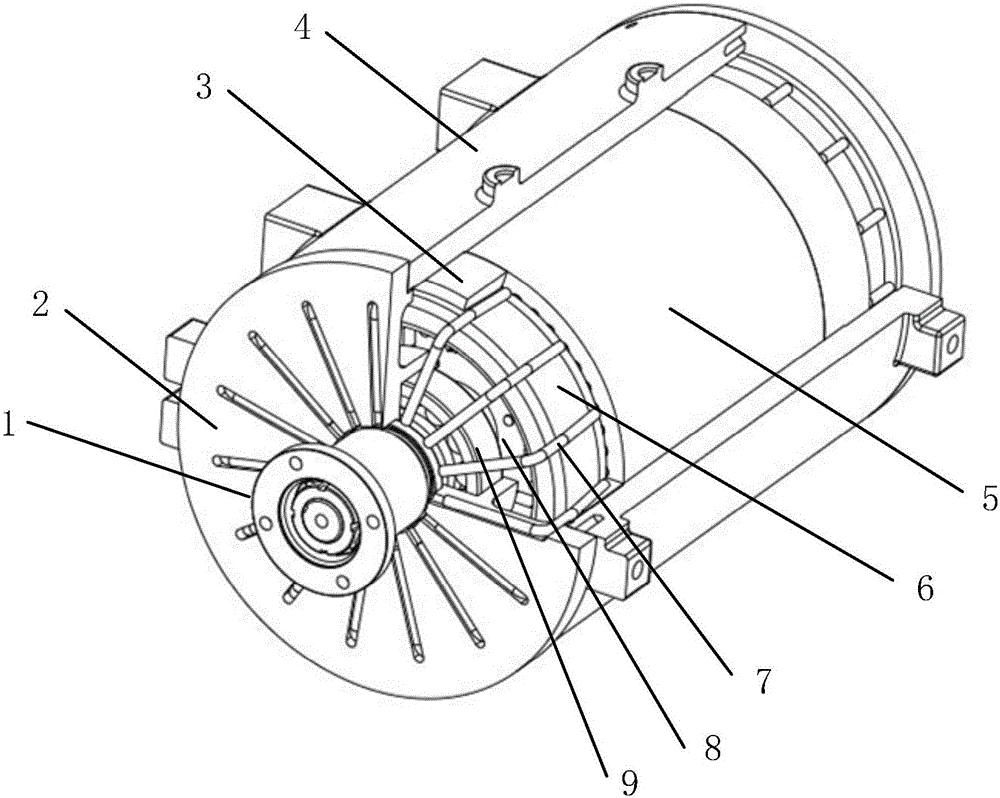

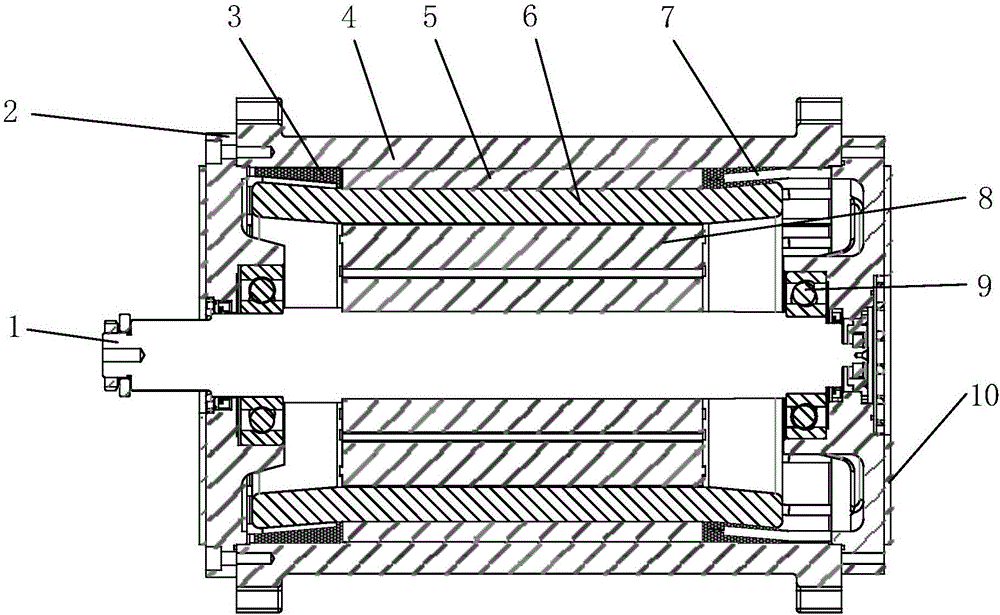

[0026] A heat pipe type winding enhanced heat dissipation motor adopts the existing permanent magnet synchronous motor structure, including a shaft and its fixing parts, two end covers, a water-cooled casing, a stator core, a stator winding, a rotor and magnetic steel, bearings, two A group of heat pipes, two heat pipe pressure tube plates. The rotor and magnetic steel are fixed on the shaft and its fixing parts. Bearings are installed between the shaft and its fixing parts and the end cover. The end covers are fixed on both ends of the water-cooled casing. And the magnetic steel is arranged sequentially from the outside to the inside.

[0027] The length of the stator core is shorter than that of the stator winding and the water-cooled casing, so that two annular cavities are formed between the three, and the electronic potting compound is filled in the cavities.

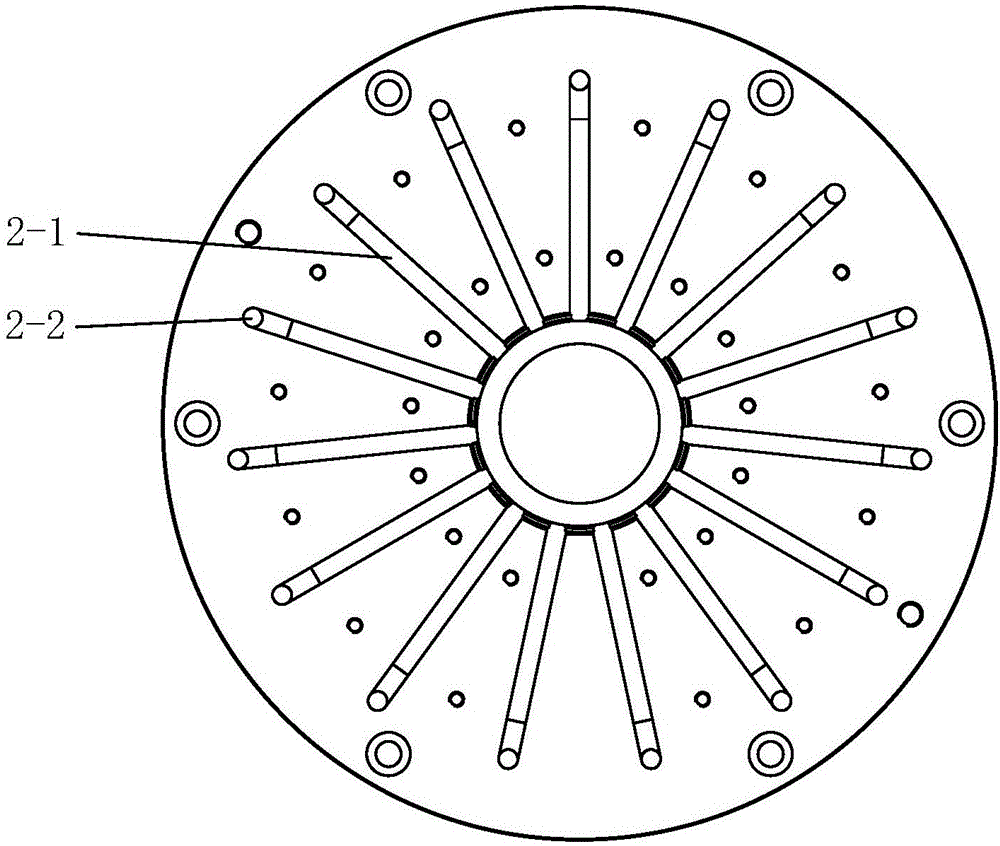

[0028] A plurality of pipe grooves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com