Method for producing sodium tripolyphosphate by utilization of crude sodium pyrophosphate

A technology of sodium tripolyphosphate and crude sodium pyrophosphate, which is applied in the refining process field of crude sodium pyrophosphate, to realize the recovery of side waste resources, high crystal purity, and improve the effect of refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

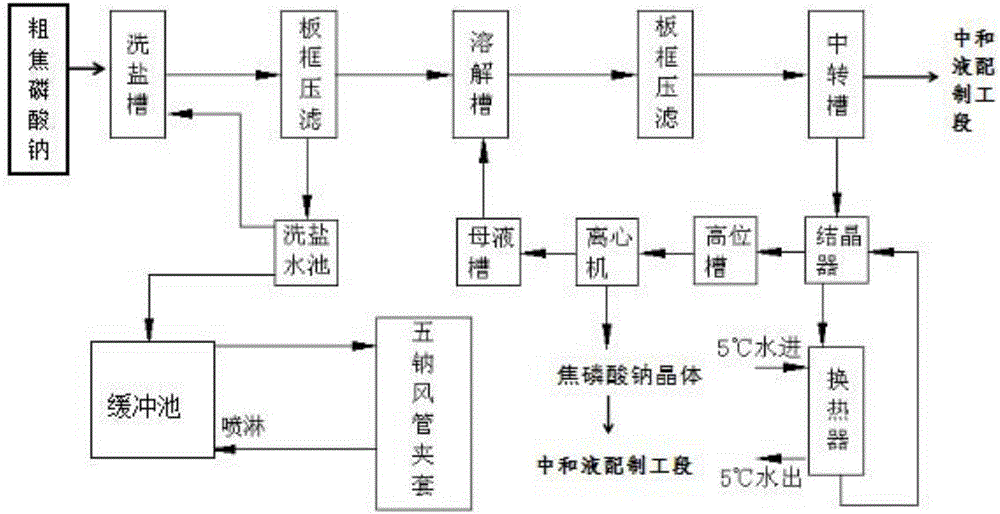

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, the crude sodium pyrophosphate first enters the salt washing tank to remove most of the sodium chloride through salt washing, and then enters the plate and frame filter press for a pressure filtration. The filter cake contains a large amount of sodium pyrophosphate, and the mass concentration of sodium chloride is less than 2.5%, then heat the solution to 85°C with steam in the dissolution tank for stirring and dissolving, add sodium sulfide to remove metal ions during dissolution, the insoluble matter is copper hydroxide and other impurities, and then carry out secondary pressure filtration, the filtrate is sodium pyrophosphate solution, add activated carbon to the filtrate to remove pigment, add phosphoric acid to acidify, accelerate dissolution, and finally add liquid caustic soda to adjust the pH value to 7.5-8.5 to prepare a refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com