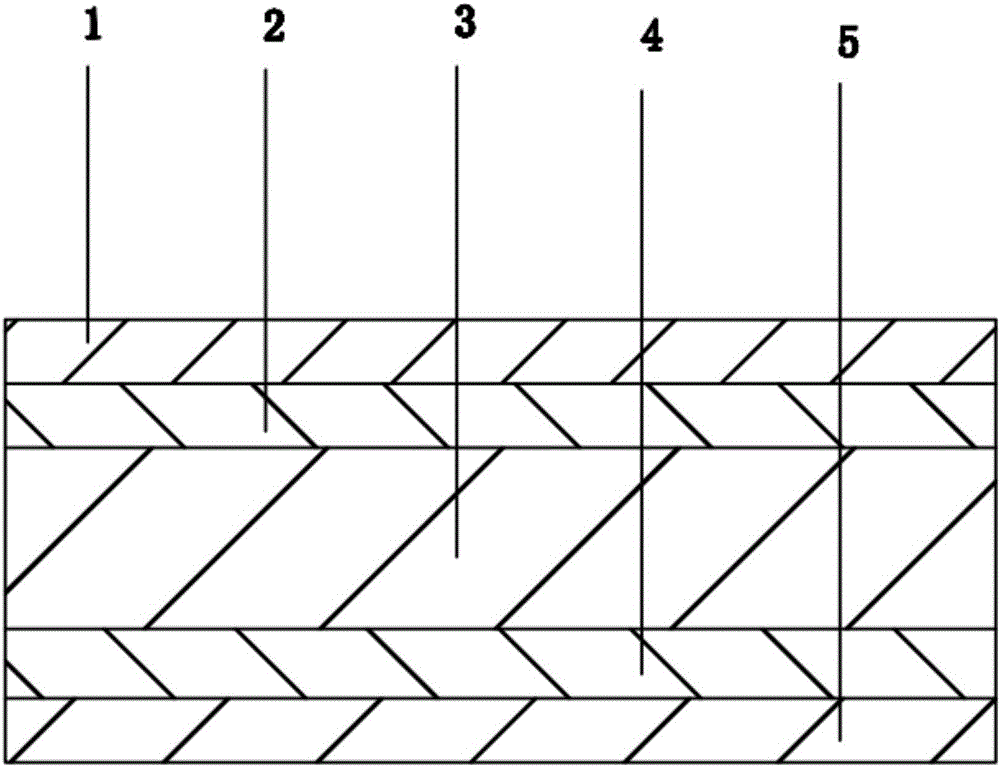

Semi-hard bamboo and wood fiber decorative base plate and preparation method and elastic self-adhesive floor

A bamboo fiber and semi-rigid technology, applied in the field of elastic self-adhesive flooring, can solve the problems of poor elasticity, easy shrinkage, and large limitations of use places of reinforced composite wood flooring, so as to increase toughness and stability, and increase surface resistance. Compressive strength, easy and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] Step 1: Mix 35kg of 80 mesh wood fiber powder, 25kg of 200 mesh calcium carbonate, 25kg of PVC resin, 5kg of EVA and 3kg of OBS organic base stabilizer (OBS organic base stabilizer is based on uracil as the basic chemical composition), DOTP paraphenylene Dioctyl diformate 7kg, mix and carry out high and low speed stirring, high speed stirring speed is 1000r / min, stirring time is 8min; Low speed stirring speed is 800r / min, stirring time is 3min; High and low speed stirring temperature is 70 ℃; After the high and low speed stirring is completed, the mixture is cooled and stirred for later use;

[0027] Step 2: Extrude the mixture obtained in step 1 through a single-screw extruder with a factory standard of 190, the temperature in the front section is 180°C, the temperature in the middle section is 170°C, the temperature in the back section is 180°C, and the extrusion speed is 180kg / hour , continuous tablet molding in the tablet machine, and then press and laminate, emboss...

specific Embodiment 2

[0031] Step 1: Mix 30kg of 90-mesh bamboo fiber powder, 30kg of 200-mesh calcium carbonate, 20kg of PVC resin, 10kg of EVA, 4kg of calcium-zinc composite stabilizer, and 6kg of DINP diisononyl phthalate and stir at high and low speeds. The stirring speed is 1000r / min, and the stirring time is 8min; the low-speed stirring speed is 800r / min, and the stirring time is 3min; the high and low speed stirring temperature is 70°C; after the high and low speed stirring, the mixture is cooled and stirred for later use;

[0032] Step 2: Extrude the mixture obtained in step 1 through a single-screw extruder with a factory standard of 190. The temperature in the front section is 190°C, the temperature in the middle section is 180°C, the temperature in the back section is 190°C, and the extrusion speed is 190kg / hour , continuous tablet molding in the tablet machine, and then press and laminate, emboss, cool, and cut into pieces to obtain the finished product.

specific Embodiment 3

[0034] Step 1: Mix 20kg of 120-mesh wood fiber powder, 45kg of 400-mesh calcium carbonate, 15kg of PVC resin, 10kg of EVA, 5kg of OBS organic base stabilizer, 5kg of DINP diisononyl phthalate and stir at high and low speeds, high speed stirring The speed is 1200r / min, and the stirring time is 10min; the low-speed stirring speed is 1000r / min, and the stirring time is 5min; the high and low speed stirring temperature is 80°C; after the high and low speed stirring, the mixture is cooled and stirred for later use;

[0035] Step 2: Extrude the mixture obtained in step 1 through a single-screw extruder with a factory standard of 190, the temperature in the front section is 200°C, the temperature in the middle section is 190°C, the temperature in the back section is 200°C, and the extrusion speed is 200kg / hour , continuous tablet molding in the tablet machine, and then press and laminate, emboss, cool, and cut into pieces to obtain the finished product.

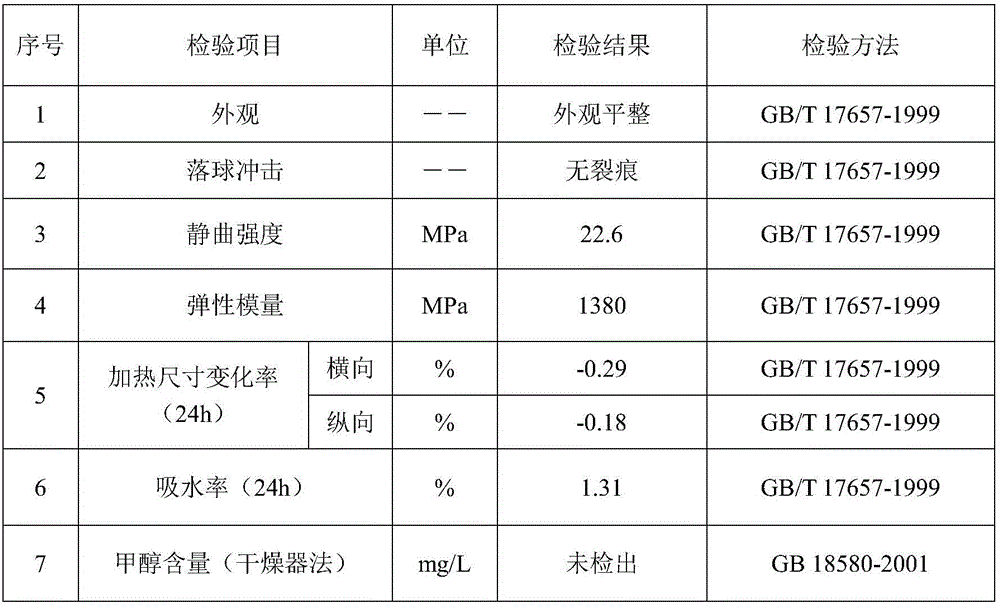

[0036] The performance detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com