Ultrasonic hydrophone sensitivity multi-frequency point absolute calibration method

An absolute calibration, hydrophone technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, instruments, measurement of vibration, etc., can solve the problems of long time consumption, cumbersome calibration process, low calibration efficiency, etc., to improve the signal-to-noise ratio, Improve calibration efficiency and reduce the effect of distance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

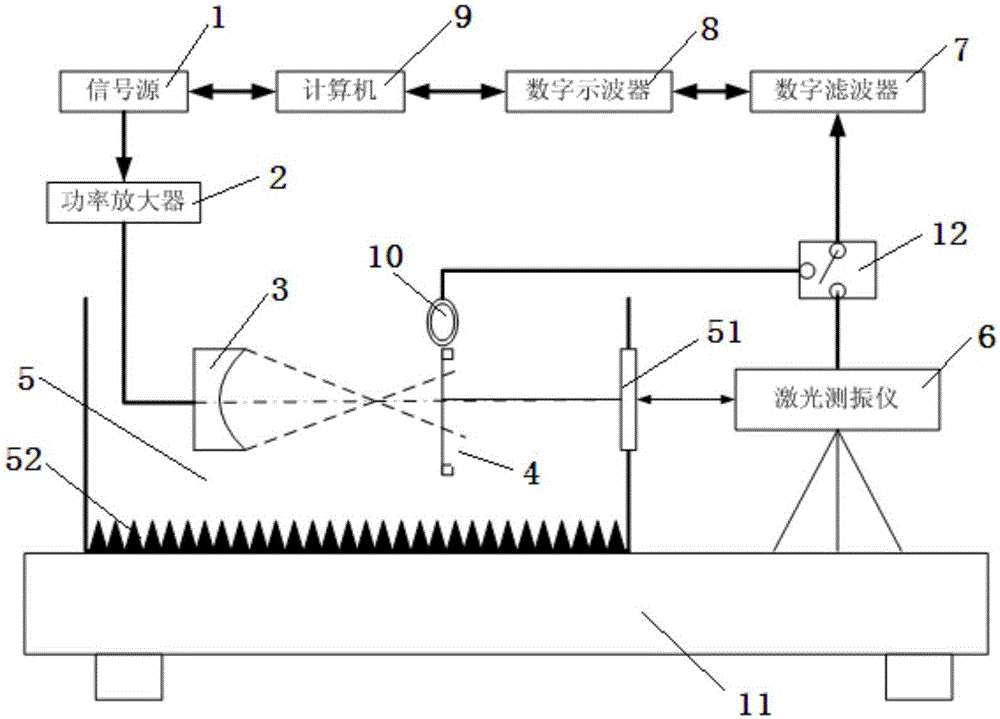

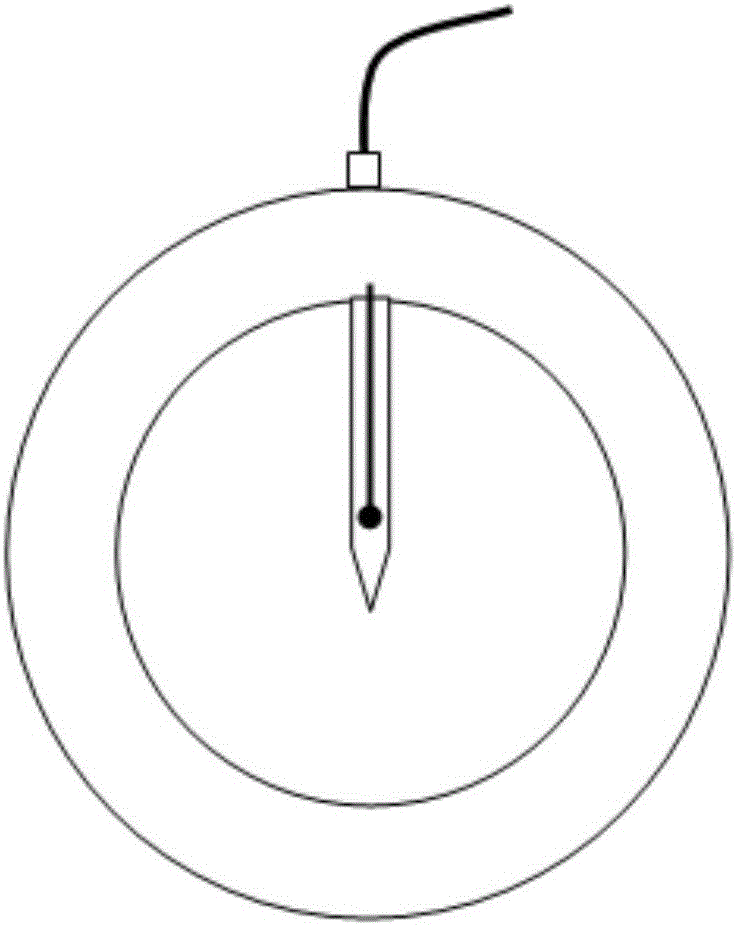

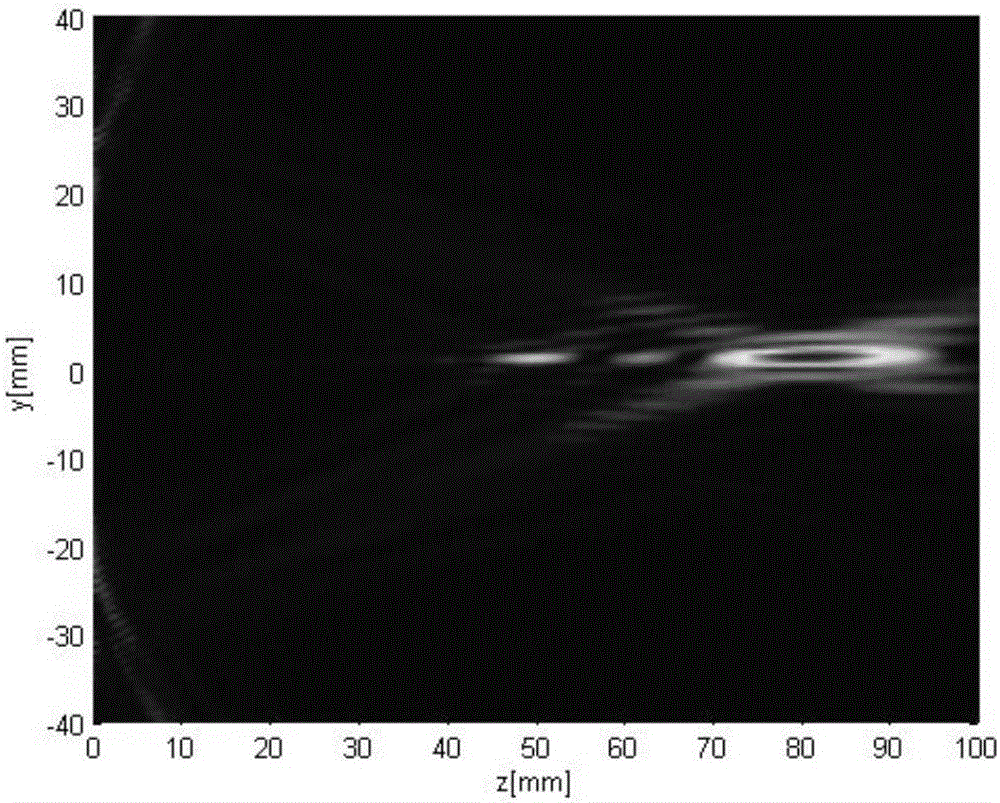

[0023] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, including signal source 1, power amplifier 2, focusing transducer 3, reflective diaphragm 4, laser vibrometer 6, digital filter 7, digital oscilloscope 8, control computer 9, measuring tank 5, hydrophone to be calibrated device 10, positioning mechanism 12 and optical vibration isolation platform 11. In that, 1), the signal source 1 generates a sinusoidal filling pulse wave signal, and after being amplified by the power amplifier 2, it drives the focusing transducer 3 to radiate sound waves into the water medium, and the focusing transducer 3 gathers the sound waves in its focal area through energy convergence The reflective diaphragm 4 is placed in the measuring tank 5, after the reflective diaphragm 4 is in the acoustic focus of the focusing transducer 3, the laser beam sent by the laser vibrometer 6 passes through the light-transmitting window 51 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com