Temperature-insensitive magnetic field sensor based on magnetic fluid filling optical fiber microcavity

A magnetic field sensor and magnetic fluid technology, which is applied in the use of magneto-optical equipment for magnetic field measurement, the size/direction of the magnetic field, etc., can solve the problems of low sensor sensitivity, reduced temperature sensitivity, and inability to achieve complete temperature compensation. The effect of large measurement range, compact structure and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

[0041] An application example of the temperature-insensitive magnetic field sensor 100 based on the ferrofluid-filled fiber microcavity of the present invention is described below.

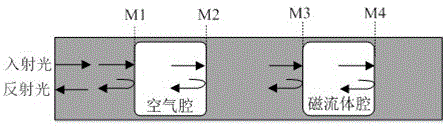

[0042] Under the action of a magnetic field, the magnetic fluid will produce a magnetorefractive effect, and its refractive index will change with the change of the magnetic field, which will lead to a change in the optical path of the fiber microcavity, thereby causing the interference spectrum of the fiber microcavity to translate. By detecting the interference spectrum The magnitude of the translation can obtain the magnitude of the measured magnetic field.

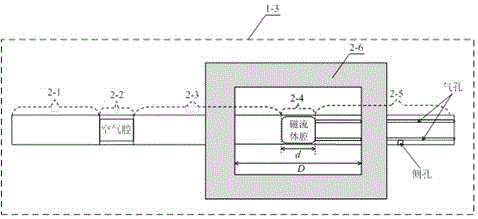

[0043] Broad-spectrum light source 1-1 adopts ASE light source, and its spectral range is 1300nm-1600nm. The broad-spectrum light emitted passes through 1×2 fiber coupler (as an example of fiber coupler 1-2) and then enters sensor head 1-3. (air cavity and magnetic fluid cavity), the optical signal reflected by the sensor head 1-3 enters t...

application example 2

[0051] The temperature compensation principle of the sensing head of the temperature-insensitive magnetic field sensor 100 based on the ferrofluid-filled fiber microcavity of the present invention will be described below.

[0052] The structure of the sensor head is as figure 2 shown. Both ends of the rectangular fiber holder are respectively fixed on the second single-mode fiber and the panda fiber, and both fixed ends are at a certain distance from the second hollow-core fiber.

[0053]The thermo-optic coefficient of ferrofluid is two orders of magnitude higher than that of quartz. Therefore, the magnetic field sensor based on ferrofluid cavity must consider the interference of temperature. This patent designs an optical fiber support structure, which uses the thermal expansion effect of the optical fiber support to offset the thermo-optical effect of the magnetic fluid. The principle of temperature compensation is analyzed as follows:

[0054] The change of the optical ...

application example 3

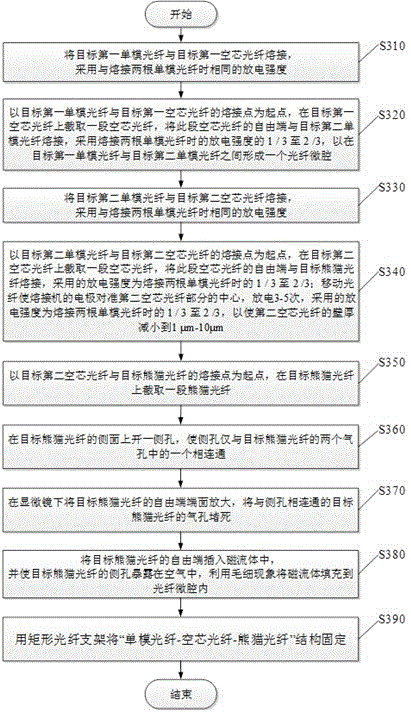

[0067] An application example for making a sensing head of the temperature-insensitive magnetic field sensor 100 based on ferrofluid-filled fiber microcavity of the present invention is described below.

[0068] First, splice common single-mode fiber (as an example of the target first single-mode fiber) with a hollow-core fiber (as an example of the target first hollow-core fiber), and the arc intensity used for fusion splicing is the same as that of splicing two common single-mode fibers under normal conditions. The strength of the fiber is the same.

[0069] Then, starting from the fusion point of ordinary single-mode fiber and hollow-core fiber, cut a section of hollow-core fiber with a length between 50 μm and 200 μm on the hollow-core fiber, and connect the free end of this section of hollow-core fiber to the ordinary single-mode fiber (Example as target second single-mode fiber) splicing. Starting from the fusion splicing point between the hollow core fiber and the ordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com