Preparation method of ferrous sulfate enteric-coated dropping pills

A ferrous sulfate enteric-coated dripping technology, applied in sugar-coated pills, pill delivery, pharmaceutical formulations, etc., can solve the problem of not producing ferrous sulfate enteric-coated dripping pills, etc., and achieves convenient taking and carrying, fast onset of action, and appearance. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for ferrous sulfate enteric-coated dripping pills, which comprises the following steps:

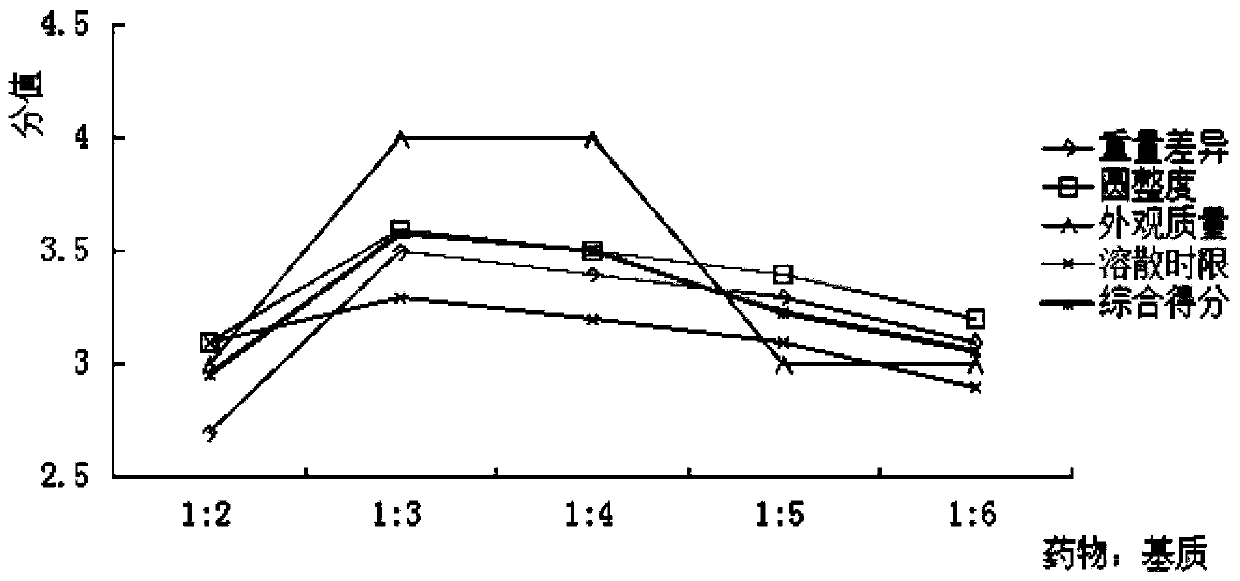

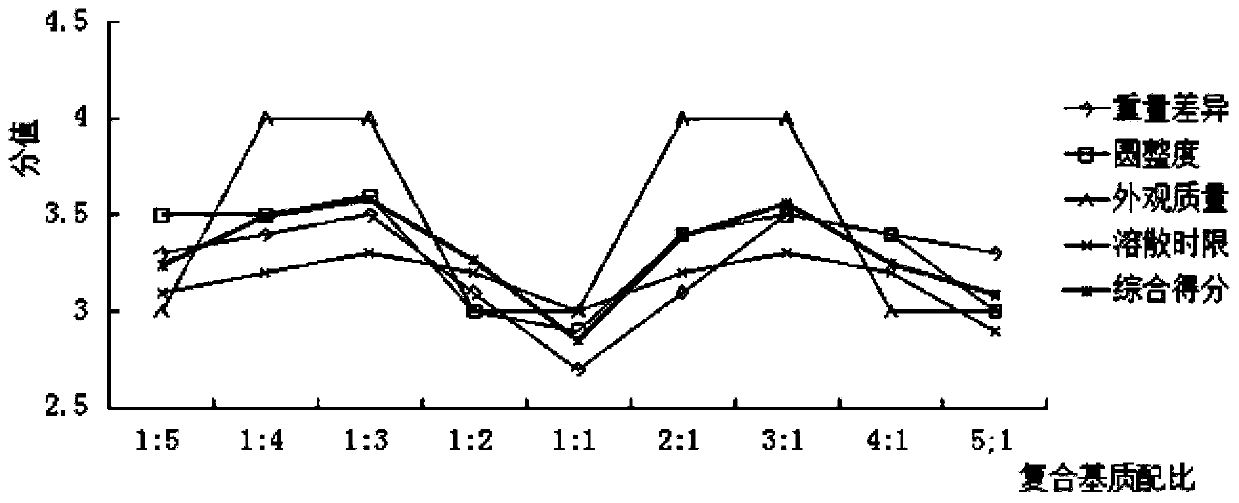

[0039] (1) Preparation of ball core: weigh the composite matrix and FeSO at a weight ratio of 3:1 4 ·7H 2 O, the composite matrix is a mixture of PEG6000 and PEG4000, the weight ratio of PEG6000 and PEG4000 is 1:4, mix PEG6000 and PEG4000 and heat to 70°C, then mix the composite matrix with FeSO 4 ·7H 2 O melts at this temperature, fully stirs, mixes evenly, obtains the medicinal liquid, keeps warm for 20min, then draws the medicinal liquid and drips it into the condensate under the conditions of a drop distance of 2cm and a drip speed of 10 drops / min, forms a pill, and stands for half a day. Take it out after one hour, wipe off the condensate, and dry it; the temperature of the lower half of the condensate is 0°C, and the condensate is paraffin;

[0040] (2) Preparation of enteric film coating solution: Soak acrylic resin No. II in an ethanol solution wit...

Embodiment 2

[0043] A preparation method for ferrous sulfate enteric-coated dripping pills, which comprises the following steps:

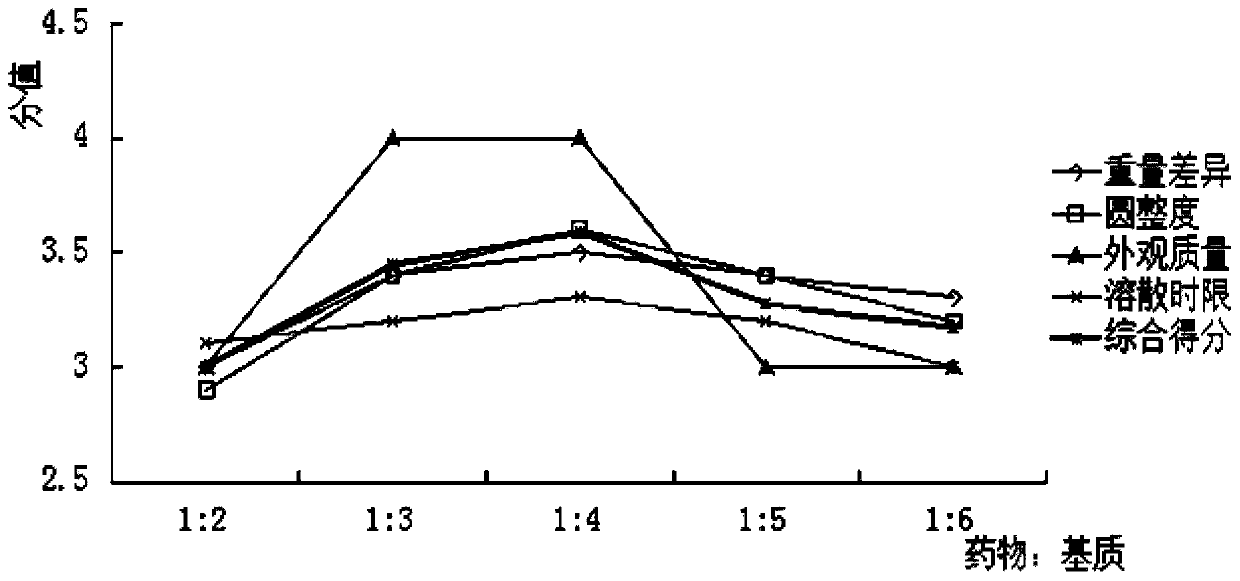

[0044] (1) Preparation of pellet core: weigh the composite matrix and FeSO at a weight ratio of 4:1 4 ·7H 2 O, the composite matrix is a mixture of PEG6000 and PEG4000, the weight ratio of PEG6000 and PEG4000 is 4:1, mix PEG6000 and PEG4000 and heat to 85 °C, then mix the composite matrix with FeSO 4 ·7H 2 O melts at this temperature, fully stirs, mixes evenly, obtains medicinal liquid, heat preservation 20min, draws medicinal liquid again and drips in the condensed liquid under the condition of drop distance 4cm, dripping speed 35 drops / min, forms pill, stands halfway Take it out after an hour, wipe off the condensate, and dry it; the temperature of the lower half of the condensate is 10°C, and the condensate is paraffin;

[0045] (2) Preparation of enteric film coating solution: Soak acrylic resin No. II in an ethanol solution with a mass content of 85% ...

Embodiment 3

[0048] A preparation method for ferrous sulfate enteric-coated dripping pills, which comprises the following steps:

[0049] (1) Preparation of pellet core: weigh the composite matrix and FeSO at a weight ratio of 5:1 4 ·7H 2 O, the composite matrix is a mixture of PEG6000 and PEG4000, the weight ratio of PEG6000 and PEG4000 is 2:1, mix PEG6000 and PEG4000 and heat to 90 °C, then mix the composite matrix with FeSO 4 ·7H 2 O melts at this temperature, fully stirs, mixes evenly, obtains medicinal liquid, heat preservation 20min, draws medicinal liquid again and drips in the condensed liquid under the condition of drop distance 6cm, dripping speed 50 drops / min, forms pill, stands for half Take it out after an hour, wipe off the condensate, and dry it to get it; the temperature of the lower half of the condensate is 20°C, and the condensate is paraffin;

[0050] (2) Preparation of enteric film coating solution: Soak acrylic resin No. II in an ethanol solution with a mass cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com