Foam light soil automatic control, feeding and stirring system

A technology of foam light soil and mixing system, which is applied in the direction of control devices, clay preparation devices, mixing operation control, etc., can solve the problems that foam light soil light materials cannot be realized, reduce labor costs and improve work efficiency efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

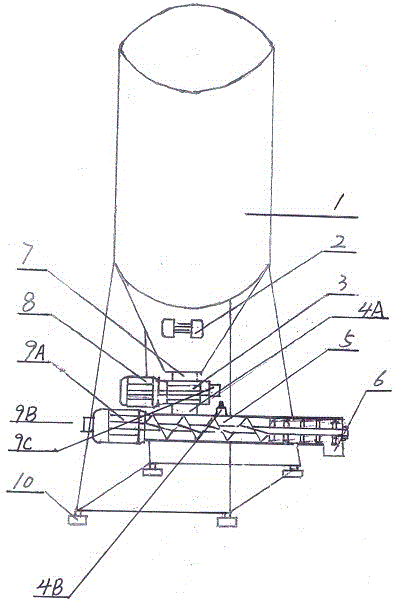

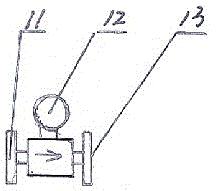

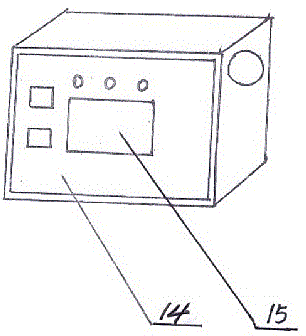

[0035] Such as Figure 1 to Figure 5 As shown: the present invention provides a foam light soil automatic control feeding and stirring system, including a stirring unit, a control unit, a monitoring unit, a regulating unit and a communication unit, and the control unit is connected with the stirring unit, the monitoring unit, the regulating unit and the communication unit, The monitoring unit is connected with the mixing unit and the regulating unit respectively, the mixing unit includes the main mixer and the feeding device, the control unit includes the PLC controller and the data memory connected to it; the feeding device includes the bulk cement storage tank, the bulk cement storage tank Air blowing holes are set at the inverted cone at the bottom, and vibration motors are set at the air blowing holes; the main mixer is connected to the bulk cement storage tank through a star meter; the monitoring unit includes a speed sensor, an electronic weighing sensor, and an electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com