Elevator compensating rope

A technology for balancing cables and elevators, which is applied to elevators in buildings, transportation and packaging, and lifting equipment in mines, etc. It can solve the problems of high density of filler formulations, cancerous human cells, and inability to meet customer needs, so as to slow down aging. Speed, extended service life, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

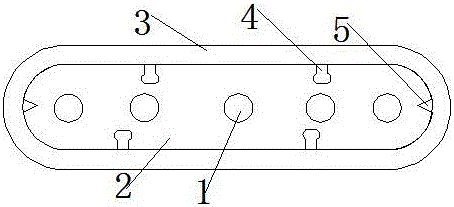

Image

Examples

Embodiment 1

[0016] Materials in the filler include: low-density calcium powder, barite powder, silicon micropowder, hard sandstone powder, fushan rock powder, stearic acid, plasticizer, desiccant, anti-aging agent, antifreeze agent, lubricant polyvinyl chloride Parts by weight are: 50 parts of low-density calcium powder, 20 parts of barite powder, 25 parts of silicon micropowder, 10 parts of hard sandstone powder, 13 parts of Fushan rock powder, 25 parts of stearic acid, 20 parts of plasticizer, and 3 parts of desiccant 4 parts, 4 parts of anti-aging agent, 3 parts of antifreeze, 6 parts of lubricant, 30 parts of polyvinyl chloride.

Embodiment 2

[0018] Materials in the filler include: low-density calcium powder, barite powder, silicon micropowder, hard sandstone powder, fushan rock powder, stearic acid, plasticizer, desiccant, anti-aging agent, antifreeze agent, lubricant polyvinyl chloride Parts by weight are: 55 parts of low-density calcium powder, 25 parts of barite powder, 30 parts of silicon micropowder, 13 parts of hard sandstone powder, 15 parts of Fushan rock powder, 30 parts of stearic acid, 25 parts of plasticizer, and 4 parts of desiccant 5 parts, anti-aging agent 5 parts, antifreeze 4 parts, lubricant 8 parts, polyvinyl chloride 50 parts.

[0019] The invention has simple structure and reasonable design, not only has the advantages of low density, high strength, high elasticity, etc., but also prolongs the service life and slows down the aging speed of the outer plastic layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com