A kind of one-pot method prepares the method for levulinic acid and sulfonated carbon catalyst

A technology of levulinic acid and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low sugar carbon utilization efficiency and resource waste , to achieve the effect of solving low sugar carbon utilization efficiency, high carbon utilization efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The concrete steps that present embodiment utilizes glucose and p-toluenesulfonic acid to prepare levulinic acid and sulfonated carbon catalyst are as follows:

[0028] (1) Mix glucose and p-toluenesulfonic acid with equal mass and put them into the reaction tank evenly, add water, the mass ratio of the water and p-toluenesulfonic acid is 0.7:1; The temperature was raised to 170 degrees, and the temperature was kept at 170 degrees for 7 hours; after the reaction, the water was cooled to room temperature to obtain a solid-liquid mixed product;

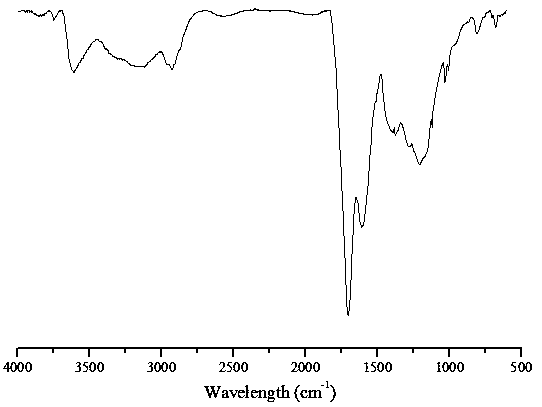

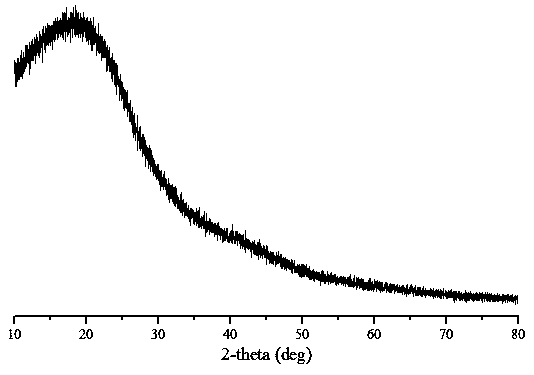

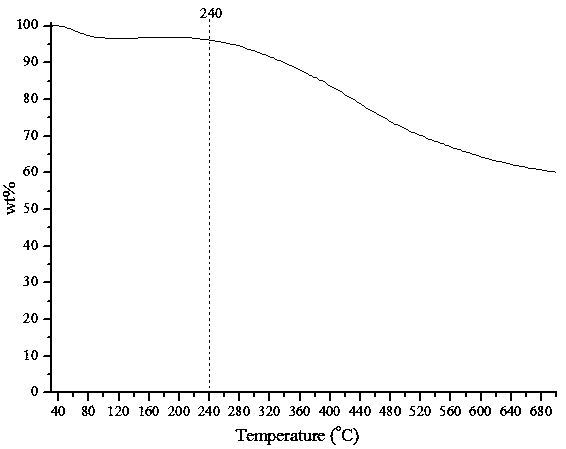

[0029] (2) The solid-liquid mixed product obtained in step (1) is washed and separated by suction filtration to obtain a liquid phase product and a solid phase product; the liquid phase product is mainly levulinic acid and p-toluenesulfonic acid; the solid phase product is at 110 degrees and dried to constant weight to obtain a sulfonated carbon catalyst.

[0030] In this example, the influence of water content on the recovery r...

Embodiment 2

[0035] The concrete steps that present embodiment utilizes glucose and p-toluenesulfonic acid to prepare levulinic acid and sulfonated carbon catalyst are as follows:

[0036] (1) Put glucose and p-toluenesulfonic acid with equal mass into the reaction tank evenly, add water, the mass ratio of water and p-toluenesulfonic acid is 0.1:1; The temperature was raised to 170 degrees, and the temperature was kept at 170 degrees for 7 hours; after the reaction, the water was cooled to room temperature to obtain a solid-liquid mixed product;

[0037] (2) The solid-liquid mixed product obtained in step (1) is washed with water and separated by suction filtration to obtain a liquid phase product and a solid phase product; the liquid phase product is mainly levulinic acid and p-toluenesulfonic acid; the solid phase product is obtained at 110 degrees and dried to constant weight to obtain a sulfonated carbon catalyst.

[0038] In this example, the influence of water content on the recover...

Embodiment 3

[0040] The concrete steps that present embodiment utilizes glucose and p-toluenesulfonic acid to prepare levulinic acid and sulfonated carbon catalyst are as follows:

[0041] (1) Put glucose and p-toluenesulfonic acid with equal mass into the reaction tank evenly, add water, the mass ratio of water and p-toluenesulfonic acid is 0.45:1; The temperature was raised to 170 degrees, and the temperature was kept at 170 degrees for 7 hours; after the reaction, the water was cooled to room temperature to obtain a solid-liquid mixed product;

[0042](2) The solid-liquid mixed product obtained in step (1) is washed and separated by suction filtration to obtain a liquid phase product and a solid phase product; the liquid phase product is mainly levulinic acid and p-toluenesulfonic acid; the solid phase product is at 110 degrees and dried to constant weight to obtain a sulfonated carbon catalyst.

[0043] In the present embodiment, water content is to the rate of recovery of toluenesulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com