Cooling method for rectification vacuum pump in ketene dimer production

A technology of diketene essence and diketene, applied in pump components, variable capacity pump parts, liquid variable capacity machinery, etc., can solve problems such as large water consumption, waste of materials, environmental impact, etc., to save energy, reduce emissions, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

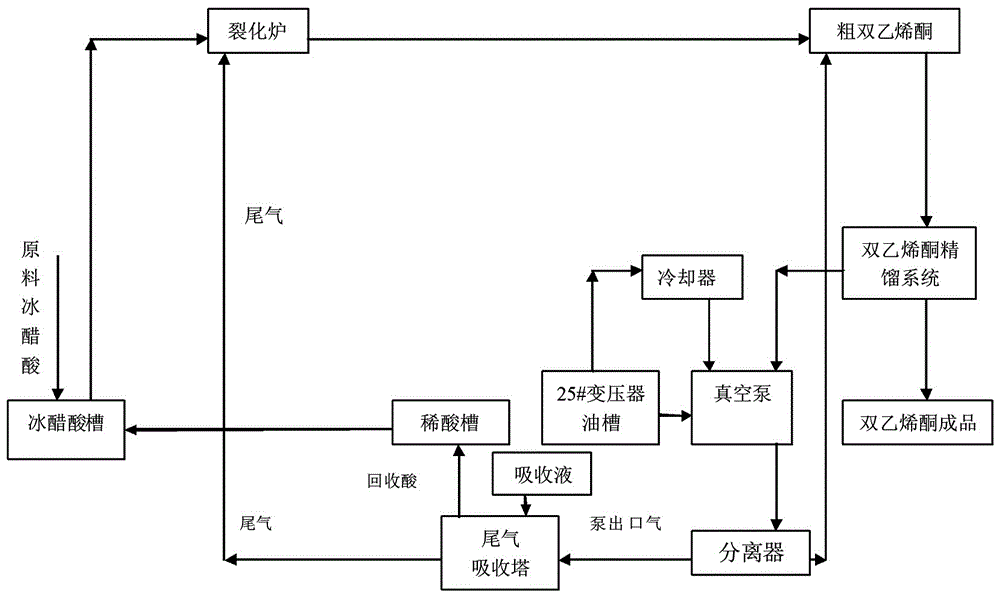

[0013] The rectification vacuum pump cooling method in diketene production comprises the following steps:

[0014] 1. After the crude diketene is produced, it is sent to the diketene rectification system and heated by a membrane evaporator. The rectification system is connected with a vacuum pump to maintain a certain negative pressure in the rectification system. Under negative pressure, the crude diketene becomes diketene vapor , through the packed tower for separation, decolorization, and further purification, and finally the gaseous diketene enters the condenser to condense into the finished product of diketene.

[0015] Put 25# transformer oil in the oil tank with cooling tubes, keep the liquid level above 200CM, 25# transformer oil overflows into the oil cooler, when the rectification vacuum pump is running, put 25# transformer oil from the oil cooler The medium is pumped into the pump body to play the role of cooling and sealing, and the oil circulation is maintained at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com