Sulfur measurement device for automatically weighing barium sulfate

An automatic weighing and barium sulfate technology, applied in measuring devices, material weighing, instruments, etc., can solve the problems of low difficulty and efficiency of barium sulfate sulfur content testing, insufficient consideration of details, and high labor intensity of workers. Excellent reliability and efficiency, simple structure and working principle, low level of personnel participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

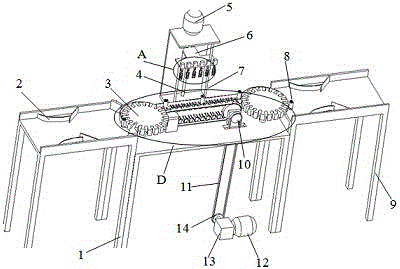

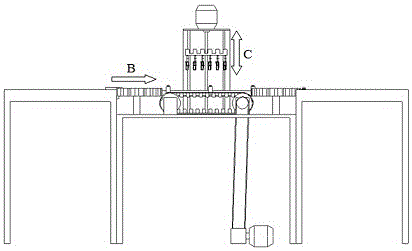

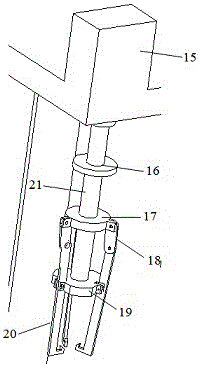

[0018] Compare below Figure 1 to Figure 4 To explain, because the device has relatively high requirements for motion timing, the connection of each component should be checked before the device works, especially the connection between the servo motor 12 and the reducer, the connection between the reclaiming turntable and the feeding turntable and the toggle The relative positional relationship of the chain ensures that the parts are reliably connected to avoid safety accidents where parts fall and hurt people. Then start the servo motor 12 and the lifting motor 5, and the reducer 3 drives the driven pulley 10 to rotate. Check Whether the sliding plate 6 moves downward when the weighing bottle 8 is transported to the clamping weighing mechanism by the chain 23, the device has completed the preparatory work so far.

[0019] When the device is working, after making the Ehrlich sample, it is placed on the combustion furnace 30 for calcination, so that the non-barium sulfate subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com